8

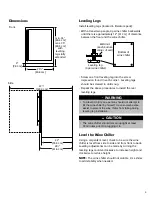

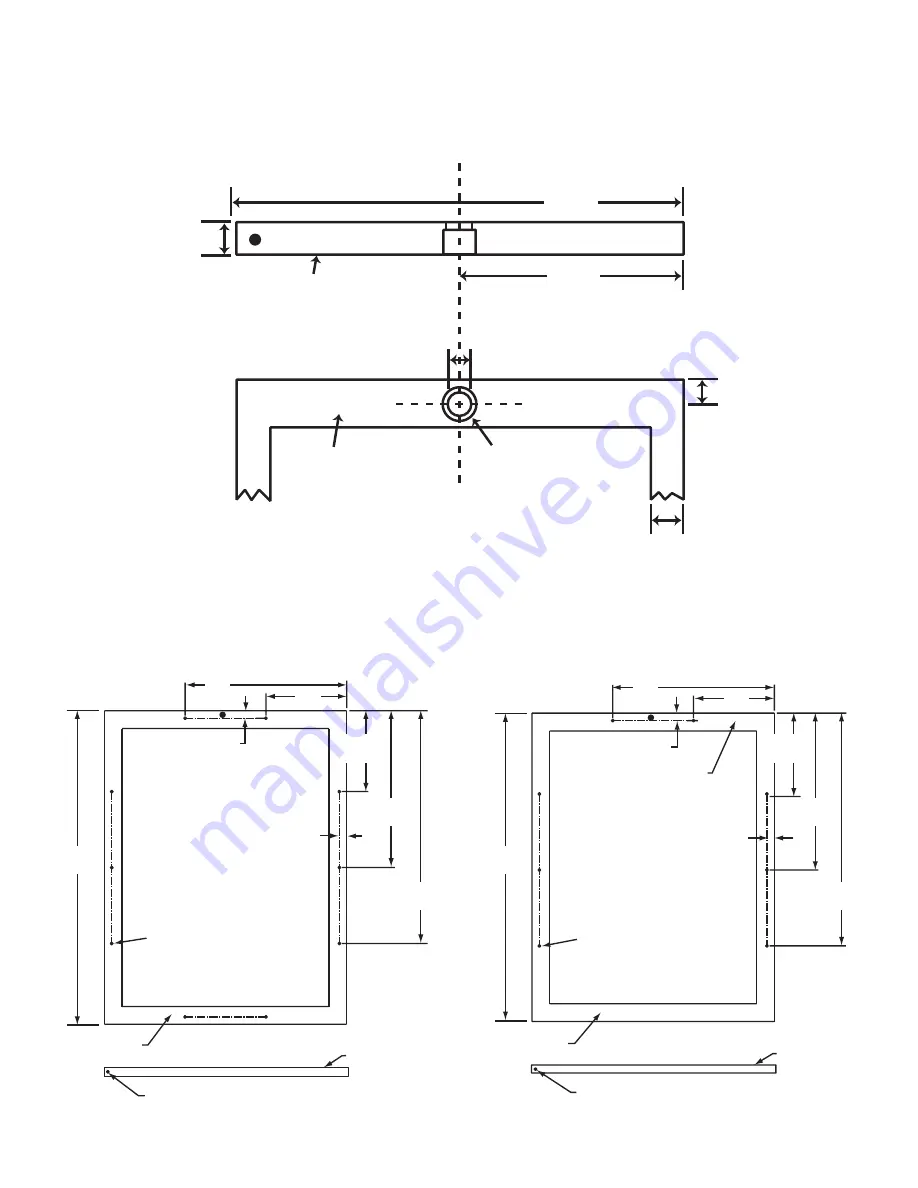

Prepare the Wood Frame

Lock Hole Detail

For a 3

1

⁄

2

" (8.9 cm) toe kick

(covers the entire door extrusion)

Optional for a 4" (10.2 cm) toe kick

(to match existing cabinetry toe kick height)

1

⁄

4

" (0.6 cm) x

3

⁄

8

" (1.0 cm) deep hinge screw clearance

hole. Locate and drill using door hinge hole after the

door has been aligned to the wine chiller and when

the wood is positioned on door.

Mounting surface

(non-face) side

Mounting surface

(non-face) side

1

⁄

4

" (0.6 cm) x

3

⁄

8

" (1.0 cm) deep hinge screw clearance

hole. Locate and drill using door hinge hole after the

door has been aligned to the wine chiller and when

the wood is positioned on door.

Mounting surface

(non-face) side

Mounting surface

(non-face) side

Pre-drilled pilot holes

10 places do not drill

through wood frame

Back side of door

Back view

Pre-drilled pilot holes

8 places do not drill

through wood frame

Back view

30

5

⁄

16

"

(77.0 cm)

29

13

⁄

16

"

(75.7 cm)

22

1

⁄

2

"

(57.1 cm)

22

1

⁄

2

"

(57.1 cm)

15

5

⁄

32

"

(38.5 cm)

7

13

⁄

16

"

(19.8 cm)

15

5

⁄

32

"

(38.5 cm)

7

13

⁄

16

"

(19.8 cm)

23

⁄

32

"

(1.8 cm)

23

⁄

32

"

(1.8 cm)

23

⁄

32

"

(1.8 cm)

23

⁄

32

"

(1.8 cm)

15

5

⁄

8

"

(39.7 cm)

7

13

⁄

16

"

(19.8 cm)

15

5

⁄

8

"

(39.7 cm)

7

13

⁄

16

"

(19.8 cm)

11

23

⁄

32

"

(29.8 cm)

23

7

⁄

16

"

(59.5 cm)

Thickness:

5

⁄

8

" to

3

⁄

4

"

(1.6 to 1.9 cm)

15

⁄

32

" (1.2 cm)

diameter through hole

Mounting surface

(non-face) side of

wood frame

Back view of overlay

wood frame panel

Center Line

13

⁄

16

" (2.1 cm)

diameter counterbore

7

⁄

16

" (1.1 cm) deep

1

23

⁄

32

" (4.4 cm)

width to cover

door extrusion

15

⁄

32

" (1.2 cm)