50

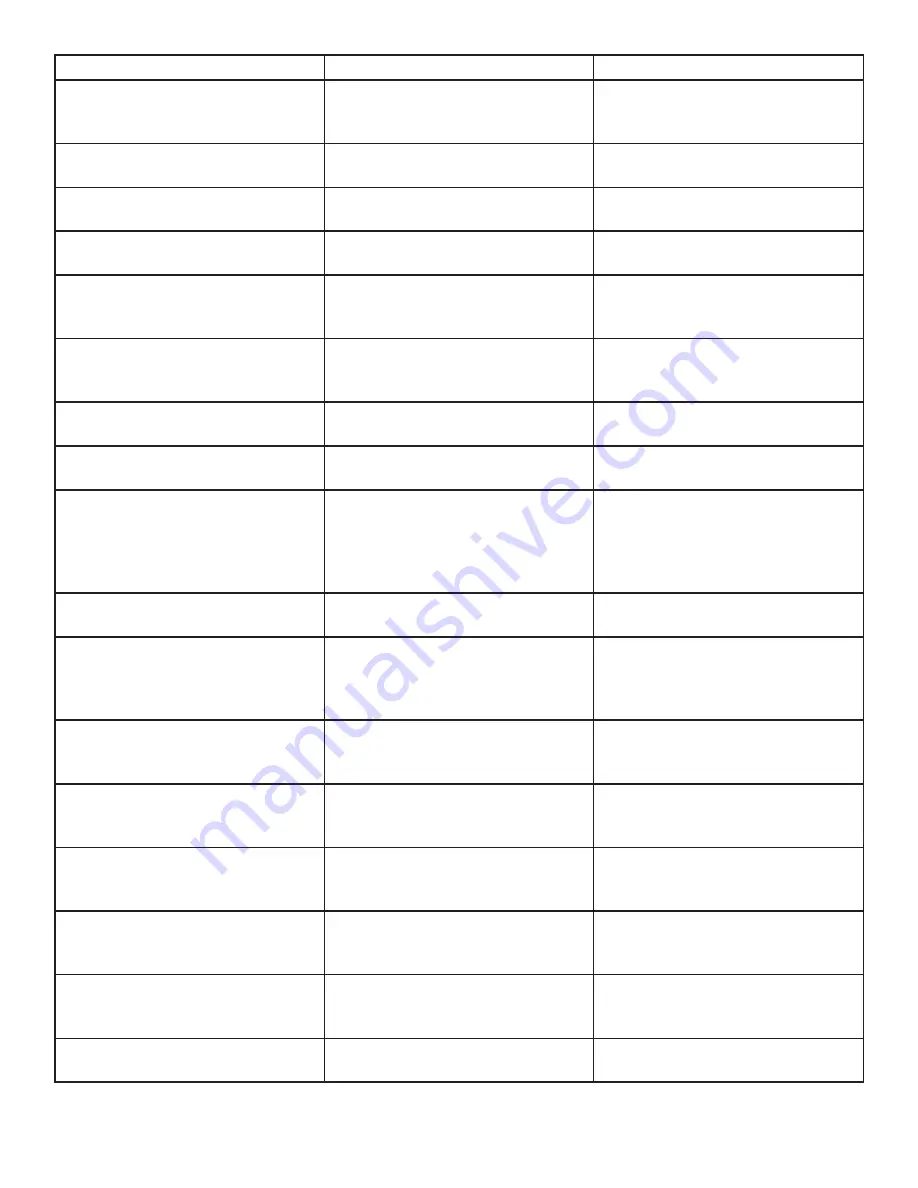

Problem

Possible Cause

Possible Solution

Connecting rod, piston pin, or

crank wrist pin bearings worn or

scored.

Inspect all. Repair or replace as

required.

Crankshaft seal worn or crankshaft

scored.

Replace seal or crankshaft

assembly.

Extremely dusty atmosphere.

Install more effective f ltration or

relocate unit.

Worn cylinder f nish.

Deglaze cylinder with 180 grit f ex-

hone.

Wrong gauge wire or length of

extension cord.

Check chart for proper gauge

wire and cord length. If possible,

eliminate extension cord.

Air compressor on unlevel surface. Do not incline the air compressor

more than 10° in any direction

while running.

Excessive starting and stopping

Compressor check valve leaky,

broken, carbonized or loose.

Clean or replace as required.

Inspect valves.

Defective motor, motor capacitor or

pressure switch.

Contact Jenny Customer Service

at 1-888-4-A-JENNY.

Air compressor is not large enough

for air required.

Check the accessory air

requirement. If it is higher than the

CFM or pressure supply of the air

compressor, you need a larger air

compressor.

Defective gaskets.

Replace and torque head bolts to 6

- 7 ft lb.

Fittings not tight enough or leaking. Warning drain air before tightening:

tighten f ttings where air can not be

heard escaping. Check joint with

soap solution. Do not overtighten.

Possible defective reed valve.

(Hand Carry Units)

Remove pump head and inspect

valve plate and (reed) valve. Clear

or replace valves as required.

Excessive noise during operation

Lubricant viscosity too low

Drain existing lubricant and ref ll

with Jenny Ultimate Blue Synthetic

lubricant.

Lubricant viscosity too high.

Drain existing lubricant and ref ll

with Jenny Ultimate Blue Synthetic

lubricant.

Lubricant level too low

Add Jenny Ultimate Blue Synthetic

Oil to crankcase to proper level.

Check for bearing damage.

Detergent type lubricant being

used.

Drain existing lubricant and ref ll

with Jenny Ultimate Blue Synthetic

lubricant.

Carbon build up on top of piston.

Clean piston. Repair or replace as

required.

Summary of Contents for Reciprocating Air Compressors

Page 4: ...4 Section 1 Safety and Health Instructions...

Page 14: ...14 Section 2 Introduction and Description...

Page 19: ...19 Section 3 Preparation for Use and Initial Installation Instructions...

Page 24: ...24 Section 4 Operating Instructions...

Page 36: ...36 Section 5 Maintenance Instructions...