2

Suitable clothing

Always wear - Safety helmet with face visor

-

Ear defenders

-

Thick gloves (Avoiding tight fitting gloves)

-

Overalls

Avoid

- Loose clothing

-

Ties

-

Anoraks with loose cords

Starting the machine

Always start with the feed rollers disengaged (‚stop‘ position).

Start the tractor, and engage the PTO, building up to 540rpm gradually.

When the tractor is running at 540rpm, engage the feed rollers by pulling lever to

‚forward‘ position.

Feed brushwood into the machine with the thick end of the branch first.

Adjust the discharge chute if necessary.

If the speed of the chipping disc should drop under load, disengage the feed rollers

(push to ‚stop‘) momentarily until full operating speed is restored, then resume

chipping.

Routine maintenance

-

Check all nuts and bolts for tightness.

-

Check drive belt tension regularly and adjust as necessary.

-

Check the condition of knives regularly. Performance of the machine is quickly

affected if the knives are blunt or damaged.

-

Take great care when removing knives from the machine, as the weight of the

flywheel can create enough movement to cause injury by trapping fingers even

when the tractor is turned off.

-

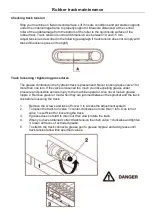

The drawing shows correct dimensions for sharpening and repositioning knives.

When the knives are too thin due to repeated sharpening, shims are available to

enable the correct setting to be achieved.

-

Ensure that the knife holder screws are tightened correctly. Check again after 1

hour’s work.

-

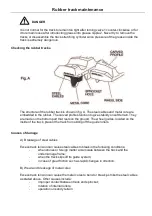

The chipper has a tapered reversible counter knife (see diagram) with two cutting

edges. A worn cutting edge may be rebuilt using hard-facing welding rods, and

regrinding (see separate instructions).

-

When replacing knives or counter knife, ensure that all surfaces behind the knife

are clean and free from dirt or wood chips.

-

Check all hydraulic screws after 5 hour’s work.

Hydraulic feed rollers – attention changed positions

When operating, always hold the lever in ‚stop‘ position for 1 second when moving

from ‚forward‘ to ‚reverse‘

Lever positions as follows:

Reverse

–

Pull lever towards operator

Forward

–

Centre position

Stop

–

Push lever towards machine