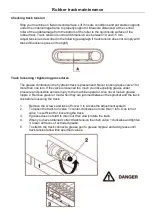

A425 Lubrication Instruction

Both bearings of main shaft (pos. 1) are filled with lithium-grease including anti-corrosive of

penetration class 3.

On normal working conditions this is sufficient for the lifetime of the bearing. The bearing

must

not

be regreased to avoid substantiel decrease of lifetime of bearings!

Lubrication for 8-working-hours-shift

Fig. No.:

Designation

Frequency

Quantity

Quantity, stroke of grease gun

1

Main shaft bearing

maintenance-free

2

maintenance-free (ball bearing)

3

joint

weekly

3

2-3, Retinax A (lube fitting)

4

telescopic section

weekly

1

2-3, Retinax A (lube fitting)

5

bearing

maintenance-free

1

maintenance-free (ball bearing)

6

pressure bar joint

(from 01/2002 up)

weekly

1

2-3, Retinax A (lube fitting)

7

pressure bar support

(from 03/2002 up)

weekly

1

2-3, Retinax A (lube fitting)

8

bearing guide

weekly

1

grease

9

turntable (optional)

monthly

3

until the grease get´s out of the

gap, Retinax A (lube fitting)

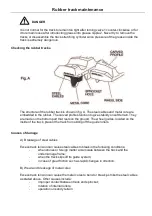

Be carefull !

If you clean the machine with a high pressure cleaner, take care that water does

not reach the bearings. This could lead to lubrication loss!