Maintenance of drive geared motors

Checking the oil level in the reduction unit

Replacement of oil in the reduction unit

IMPORTANT

Avoid using oils with different characteristics and brands.

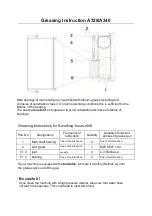

Choice of type of reduction unit oil

We recommend, for reduction units, using gear oils with E.P. additives and viscosity class

according to ISO VG 150 or SAE 80W / 90. When temperature variation ranges are very

high we recommend using synthetic oils with E.P. properties and minimum 165 viscosity

index and viscosity class VG.

VG 100

VG 150

VG 320

VG 150 – 200

ISO 3448

-20°C +5°C

IV 95min

+5°C +40°C

IV 95min

+30°C +50°C

IV 95min

-30°C +65°C

IV 165min

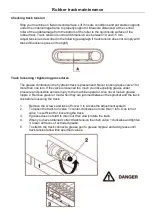

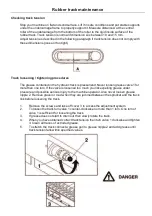

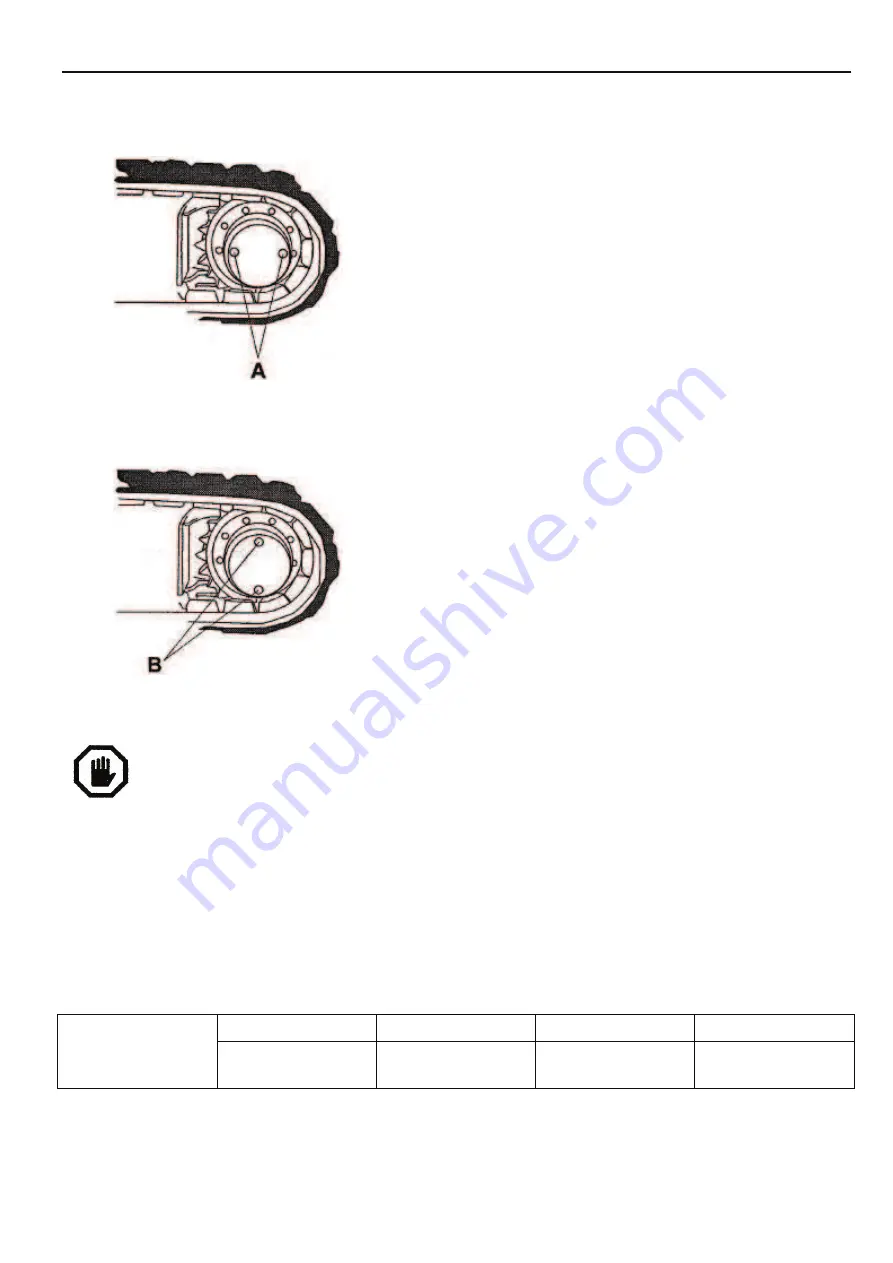

Every 100 hours check the oil level in the reduction unit

gearbox. Stop the hydraulic geared motor with plugs

aligned horizontal. Remove the plugs as shown in fig. A and

check that the oil level is up to their holes. Top up as

necessary, filling through one of the holes and using the

other to check the oil level.

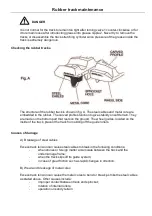

Replace the oil after the first 100 operating hours and then

at subsequent 1000 hour intervales. Proceed as follows to

perform the replacement:

-

Stopp the reduction unit with the plugs aligned

vertically as illustrated in fig. B.

-

Remove both plugs and drain out all the oil.

-

Now position the plugs horizontal (fig. A) and fill

the reduction unit through one hole, using the

other to check the oil level.