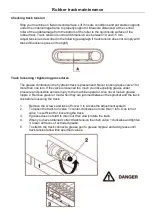

Rubber track maintenance

DANGER

It is not normal for the track to remain too tight after turning valve 1 counter-clockwise or for

it to remain loose after introducting grease into grease nipple 2. Never try to remove the

tracks or disassemble the track-stretching cylinder since pressure of the grease inside the

track is extremely dangerous.

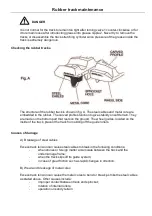

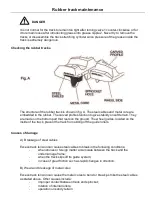

Checking the rubber tracks

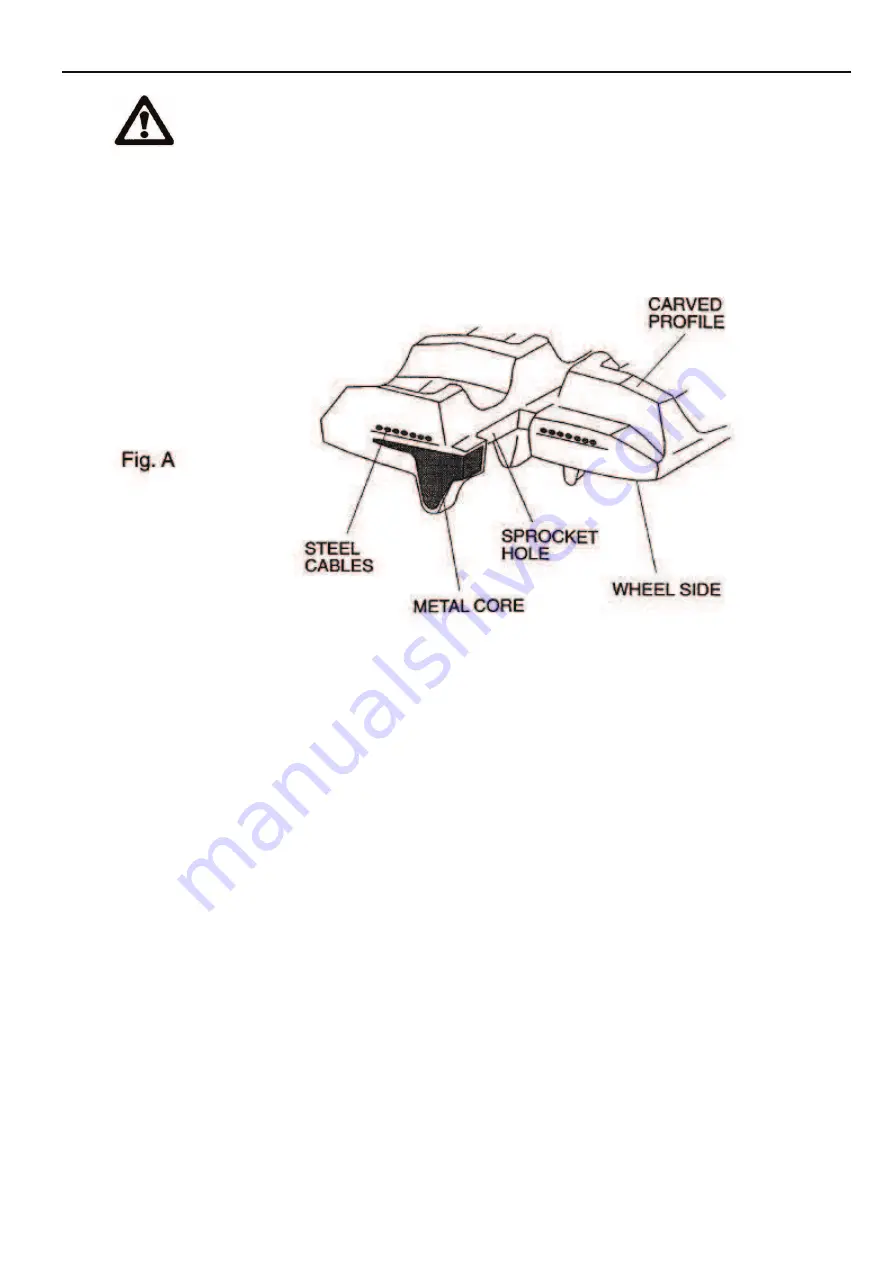

The structure of the rubber track is shown in fig. A. The steel cables and metal core are

embedded in the rubber. The carved profiles function to give stability on soft terrain. They

are made on the bottom part that rests on the ground. The wheel guides, located on the

inside of the track, prevent the track from sliding off the guide rollers.

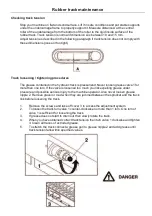

Causes of damage

A) Breakage of steel cables

Excess track tension can cause steel cables to break in the following conditions:

-

when stones or foreign matter accumulate between the track and the

undercarriage frame;

-

when the track slips off its guide system;

-

in case of great friction such as rapid changes in direction.

B) Wear and breakage of metal cores

Excess track tension can cause the metal cores to bend or break just like the steel cables

as stated above. Other causes include:

-

improper contact between track and sprocket;

-

rotation of internal rollers;

-

operation on sandy terrain.