9

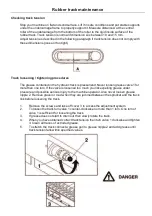

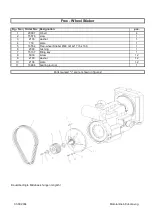

Mounting the locking element – KTR 400

Torque

All screwshave to be tightened to the proper torque by using a torque-wrench.

Fastening the screws below or above the proper value decteases the maximum

torque-transmission. Due to different values of surface-friction even a proberly set

locking element might differ up to +/- 25% in ist torque-transmission.

Screw

Force Fv[N]

Torque Ta[Nm]

M8

27900

41

Mounting

-

The force transmission depends on the friction between the element and the

shaft. A clean surface and the proper torque of the screws are of major

importance to the correct function.

-

Fasten all screws evenly and crosswise up to the torque Ta in several steps. Use

a torque-wrench.

-

Controll all screws for proper torque. If possible re-controll the screws after a test-

run of the machine.

-

Clean used and dirty locking elements. Apply a thin oil-film to all parts and

reassemble the element.

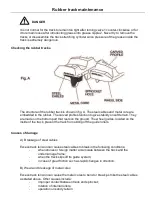

Unmount the element by removing the screws. Remove the front-ring by screwing

four screws into the four extra threads. After removing the front-ring four other extra

threads will be visible. These are used to press out the rear-ring by screwing four

screws into the threads. Use screws of the same size for disassembling as they are

used for assembling the locking element.