- 3 -

[1]

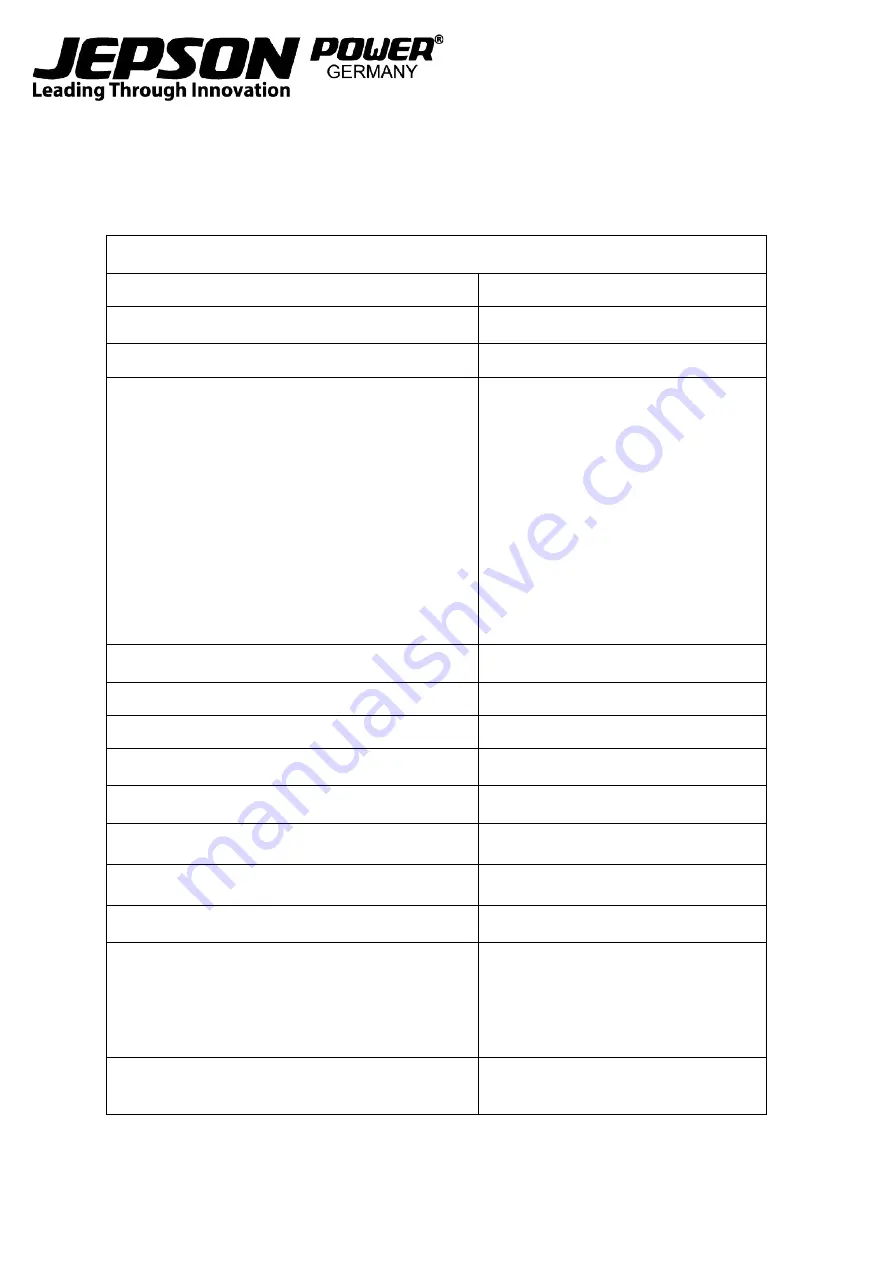

SPECIFICATIONS OF MAGNETIC DRILLING MACHINE

[MODEL Magpro40/ 1S Adjust Swivel, Reference: 490140S]

Maximum hole cutting capacity in .2/.3C steel =

4

0mm dia. x 50mm depth

Motor Unit

Voltages

220/240V(100/110V), 50/60Hz

Rated output

1,100 W

Magnet Size

155 x 78 x 45 mm

Magnet Force at 20°C with

20 mm minimum plate thickness

The use on any material less than 20mm thick

will progressively reduce the magnetic

performance. If possible, substitute material

should be positioned under the magnet and

work piece to equate to a suitable material

thickness. If this is not possible, an alternative

secure method of restraining the machine

MUST be used.

420kgf at drilling point

Overall Dimensions

Height - maximum extended

540mm

Height - minimum

340mm

Width (including Hand wheel)

190mm

Length Overall (including Guard)

230mm

Stroke

150(200)mm

RPM ( No LOAD )

450

Net Weight

12.0kg

Maximum hand/arm vibration magnitude

(measured at handle during operation in

accordance with ISO5349, using a 22mm

cutter through 13mm MS plate)

0.82 m/s²

Average noise level during cutting at

operators ear position.

90dB(A)