MAGPRO 35

6 of 10

Use of replacement parts or parts which are not approved by

the manufacturer;

Incorrect operation;

Removal, manipulation or non-use of safety or protective

equipment;

Change of function;

Changes to the magnetic drill;

Incorrect repair or maintenance;

Unintended or improper use.

Foreseeable incorrect operation

The magnetic drill can be dangerous if it not used correctly or

not used for its intended purpose.

The instruction manual must be available at all times when the

machine is use and over the entire period of operation of the

machine. Keep this instruction manual together with the magnet-

ic drill!

The magnetic drill is only guaranteed safe to use if used correct-

ly and for its intended purpose. The limit values which are stated

may not be exceeded under any circumstances whatsoever.

The information and instructions in the operat-

ing manual must be followed without fail! The

manufacturer shall not be responsible and the

warranty of the manufacturer shall lapse if the

magnetic drill is used in any other way than

described in the manual.

Caution

Hazardous substances must be disposed of so

that there is no risk to persons or the environ-

ment. Leakage of hazardous substances leads

to hazard to the environment. The relevant legal

regulations must be observed.

4.3

Transport and Storage

Dispose of packaging and insulation in a

proper and environmentally-friendly fashion.

Observe the relevant national rules and

regulations.

Store the magnetic drill in such a way that

damage is avoided.

Caution

Store the magnetic drill complete with all

individual parts and accessories, as other-

wise important parts could be missing when

the machine is recommissioned.

Caution

Use the transport box for transportation and

storage.

4.4

Functional Description

The magnetic drill adheres to mild non-alloy steel and works

with a drill motor which is attached to a stand.

Either a core drill or a twist drill is used (accessories).

5

Installation, Commissioning and

Transport

5.1

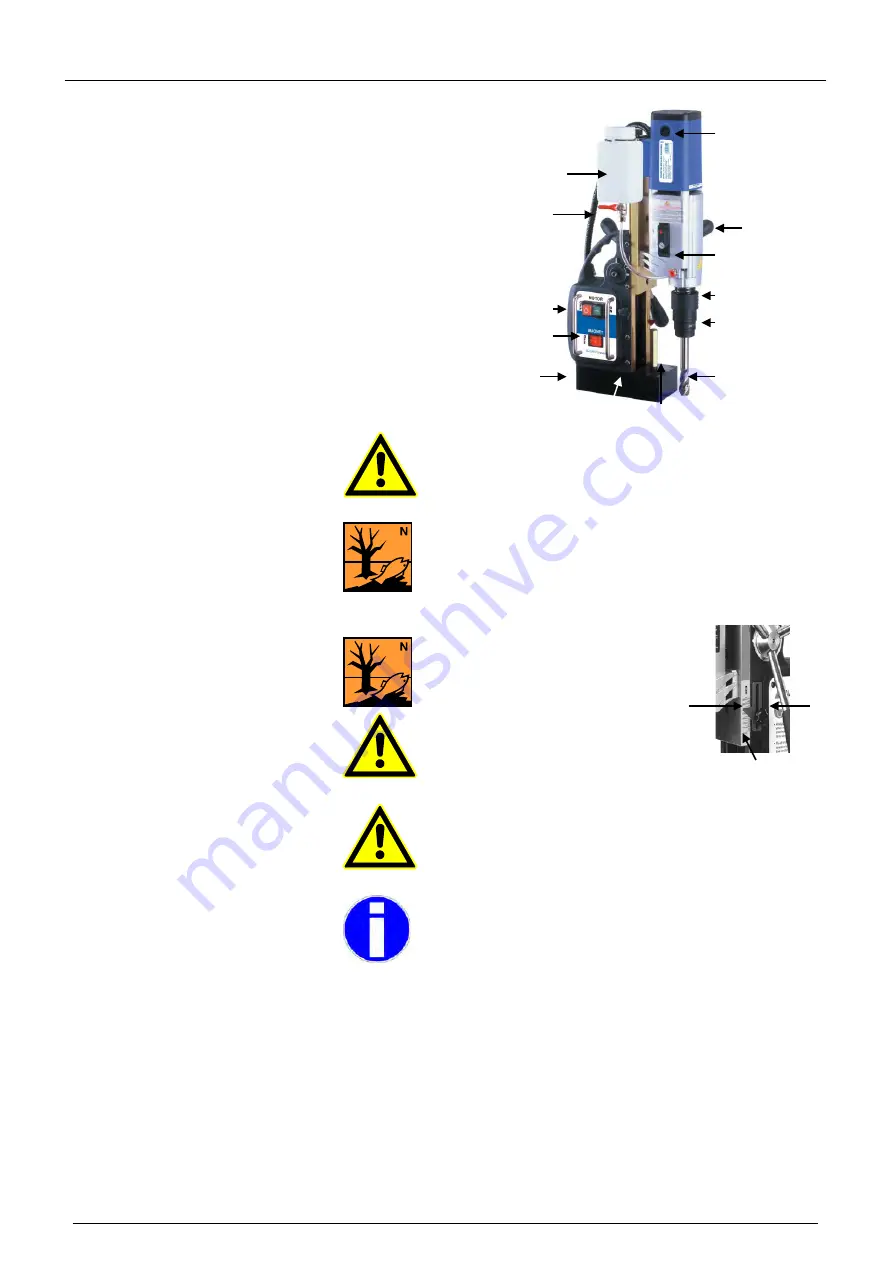

Assembling and Components

1.

Brush cap

2.

Crank handle

3.

Mode selector for shifting to Auto-reverse tapping mode

or standard drilling mode)

4.

Quick release collar

5.

Tap collet arbor

6.

Tap (not included)

7.

Travel limiter stop

8.

Gib adjuster screw

9.

Magnet

10.

Magnet switch

11.

Motor Swich

12.

Coolant feed tap

13.

Coolant tank

14.

Lock Knob

15.

Adjustable pointer

16.

Depth meter scale

5.2

Technical Data

Drill motor unit

230V 50Hz

Power input

1100 W

Drilling Mode (No / Full load speed)

550 / 330 rpm

Tapping Mode (No / Full load speed)

150 / 190 rpm

Total Stroke

150 mm

Magnetic Adhesion

15.000 N

Net weight

13,7 kg

Generation of noise (Lpa)

89 +/- 0,5 db (A)

Generation of noise (Lwa)

100 +/- 0,5 db (A)

Hand-Arm-Vibration

2,4 +/- 0,5 m/s

2

Cut. max. diameter x depth

35 x 55 mm

Core Drills

Up to Ø 35 mm

Core Drill adapter

Weldon shank , set

screw type

Taps

M12 to M20

5.3

Assembly / Mounting

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16