MAGPRO 35

7 of 10

We recommend inspecting all the items delivered for complete-

ness and any transport damage. Complaints are generally only

accepted if they are registered on the day they are received.

Assembly of coolant tank

First attach clear tube to the bottom of the coolant tank. To do

this, first loosen the nut and slide nut onto the tube. Then slide

tube onto the nipple. Then tighten the nut.

Slide tank hanger over the screw on the upper right hand side of

slide and tighten.

Finally insert the other end of the tube into the connector in the

gearbox. Just directly push in to install. (To remove, first firmly

push the collar of the connector and pull the tube out.)

Cutting coolant fluid is always required when using annular

cutters. Open tank cover and fill. Check coolant fluid level often.

Keep coolant tap closed when not in use. Empty coolant tank

when returning the machine to the carry case.

Chip guard must be used.

To attach the chip guard,

use the sup-plied butterfly bolts to bolt to the magnet. It

is not necessary to remove guard to clean chips. Simply

raise guard to its upper position.

Warning

Safety chain must be used.

Loop chain around the

work piece and feed through the machines handle and

clip in place. MOUNTING ANNULAR CUTTERS:

CAUTION: Never use a cutting tool, which is larger than

the maximum rated capacity of the machine.

Warning

5.4

SPECIAL INSTRUCTIONS FOR

AUTO-REVERSE TAPPING

MODELS

THIS MACHINE IS THE FIRST OF ITS KIND SO

SPECIAL CARE MUST BE PAID TO THE

OPERATING INSTRUCTIONS BELOW TO

UNDERSTAND ITS TAPPING FUNCTION.

CAUTION: Before beginning tapping ensure that

the hole is the correct size for the tap. An under-

size hole will cause the tap to jam causing a

hazardous situation.

CAUTION: When tapping a blind hole always

correctly use the travel limiter stop to ensure

that there is enough clearance so that you do

not bottom-out the tap. Bottoming will cause

the tap to jam, causing a hazardous situation.

CAUTION: Never attempt to tap with the gear-

box selector in standard drilling mode.

The much higher speed of the standard drilling

mode will damage the tap and cause a hazardous

situation .

COOLING:

The automatic through the spindle cooling

function is only effective when using annular cutters.

When tapping or using twist drills, cutting oil must be

added manually.

5.4.1 Setting up for tapping

CAUTION: Never use a cutting tool which is larger

than the maximum rated capacity of the machine.

CAUTION:: Always follow the tap manufacturer ’ s

recommendation for selecting the correct size hole

for tapping.

CAUTION: Never attempt to change gears on a

running machine! Only change gears when the

Caution

machine is at rest.

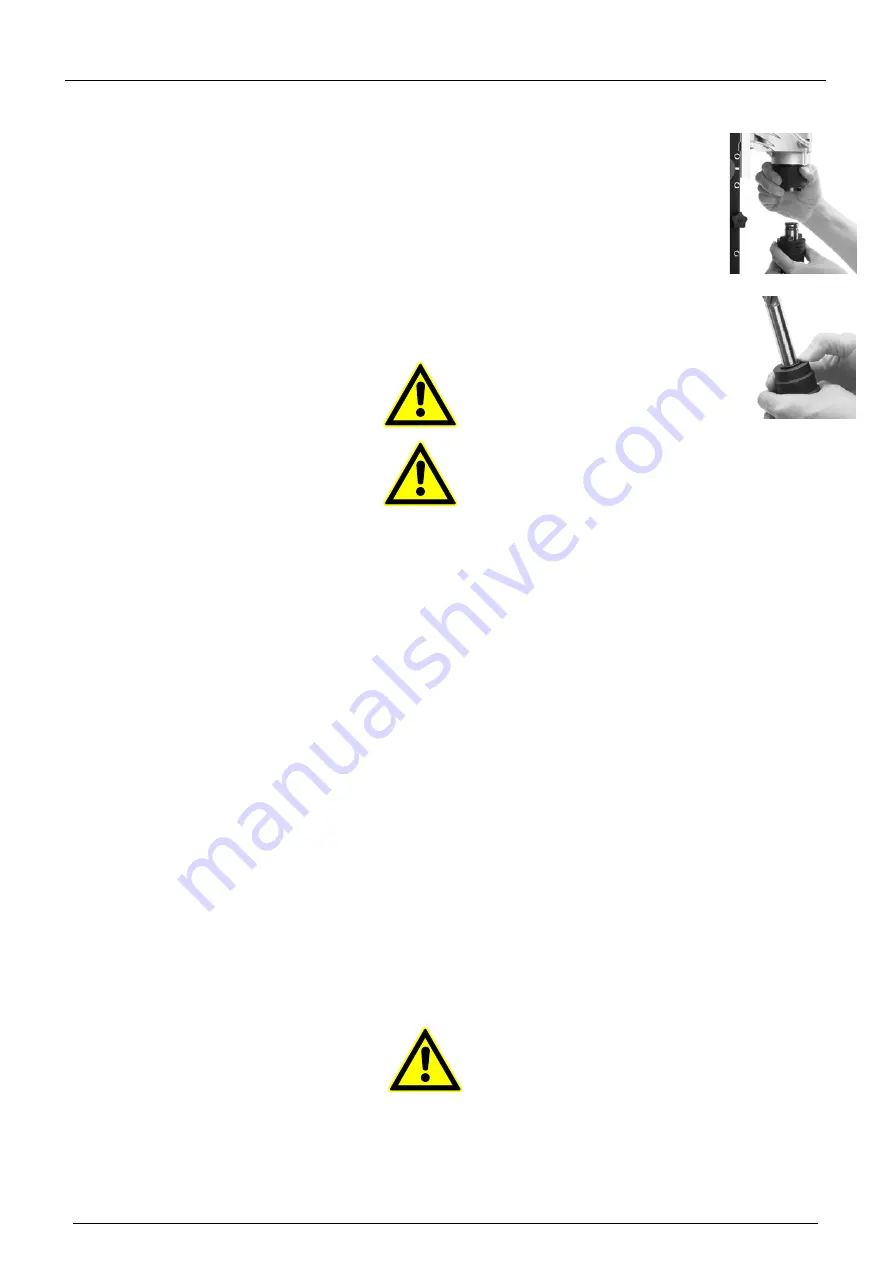

1.

Select the correct sized Tap Collet

Arbor for the tap which you intend

to use. If there is already another

arbor in the machine, simply push

up on the Quick-Release Collar and

remove.

2.

To insert the Arbor, push up on the

Quick-Release Collar (1) and insert

the Arbor (2). Turn the Arbor until

the tangs line up and the Collar is

able to close. Ensure that it is se-

curely in place.

3.

Insert the tap into the Tap Collet

Arbor. Push up on the tap and turn

it until it snaps in place. When it is

time to remove the tap from the Ar-

bor, depress the Release Ring (3)

on the Arbor. (Catch the tap so that

it does not fall on the floor when it

releases.)

4.

If it is in drilling mode, shift the gearbox to tapping mode by swing-

ing the gear selector tab out of the detent slot then shifting down-

wards into tapping mode. Then pop the selector tab back into the

detent . It will sometimes be necessary to turn the spindle by hand

a little to get it to shift all the way. Only grab the arbor when turn-

ing the spindle, never the quick-release collar. Otherwise, it will be

easy to accidentally release the arbor and it will fall out. Follow the

“TAP” symbol on the gear case. (The small arrow on the tab will

be pointing upwards when it is shifted correctly).

5.4.2 Setting the depth meter

THE PROPER USE OF THE TAPPING DEPTH METER:

Whenever tapping blind holes, the Tapping Depth Meter in conjunction with

the Travel Limiter Stop must be used for ensuring the prevention of possible

damage to the gearbox and the tap.

ALWAYS ENSURE THAT THE HOLE ISN’T OVER TAPPED. THE HOLE’S DEPTH

MUST BE MUST BE LONGER THAN THE NEEDED THREADING DEPTH!!

•

Pre-place the tap against the work piece. To zero-in the needle.

•

While keeping the tap against the workpiece, adjust the pointer to

the 4mm datum position on the left-hand tapping scale. (The tapping

function has an extra 4mm movement when the crank handle is released,

a 4mm pre-adjustment has been made on the scale. Therefore, when

"zeroing-in" the tapping scale, the 4mm mark is the effective datum

point. A minimum depth of 5mm can be tapped and a maximum of

40mm). Now that you have the depth scal e calibrated, you may use the

meter reading to set the Travel Limiter Stop.

1

2

3