MAGPRO 35

9 of 10

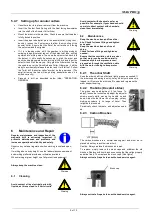

5.4.7 Setting up for annular cutters

•

If another arbor is in place, remove it from the machine.

•

Insert the Coolant Feed Spring with the Seal facing downwards

into the shaft of the Annular Cutter Arbor.

•

Mount the arbor into the machine. Check to ensure that the arbor

is fully locked in position.

•

Insert the proper sized pilot pin in the annular cutter. Using the L-

hex key, loosen the 2 set screws to allow the mounting of the

annular cutter. Ensure that the flat of the cutter shank is facing

the set screw and then tighten.

•

If it is in tapping mode, shift the gearbox to drilling mode by

swinging the gear selector tab out of the detent slot then shifting

upwards into drilling mode. Then pop the selector tab back into

the detent. It will usually be necessary to grab the arbor and

push the spindle upwards while turning a little by hand to get the

selector to shift all the way up. Only grab the Arbor when turning

the spindle, never the Quick-Release Collar. Otherwise , it will be

easy to accidentally release the arbor and it will fall out. Follow

the Twist drill & annular cutter” symbol on the gear case. (The

small arrow on the tab will be pointing downwards when it is

shifted correctly).

•

Proceed to drill as described below titled: "OPERATION-

GENERAL

6

Maintenance and Repair

Regular maintenance and inspection of the

magnetic drill is extremely important. It

prevents disturbances and problems and

increases operational reliability and safety.

Observe any national regulations when working in confined spac-

es!

If working above body height, use the ladders/access equipment

and working platforms provided or otherwise available.

When working at great height, use fall prevention equipment!

Always keep the machine clean.

Warning

6.1

Cleaning

Avoid contact of live electrical parts with

liquids, as this can lead to "short circuits".

Warning

Avoid contact with chemicals as far as

possible. For example, if your hands should

come into direct contact with chemicals,

clean them immediately.

Warning

6.2

Maintenance

Keep the machine clean and free of de-

bris. Check for loose fittings and tighten

as needed

Keep the machine clean and free of

chips.

Check for loose fittings and tighten as

needed.

Warning

Ensure that the ventilation slots are clear

so that motor can be cooled normally.

Occasionally blow low-pressure com-

pressed air through the ventilation slots

with the motor running to keep motor

clean. .

Warning

6.2.1 The arbor Shaft

Keep the arbor shaft free of dirt and lightly grease as needed. If

the arbor support bearing is noisy, it may be dirty or have a chip

lodged in it. Remove the arbor shaft to clean and re-grease the

arbor support bearing.

6.2.2 The Gibs (Dovetail slides)

The gibes require adjustment if too loose. To

adjust, loosen the locknuts and adjust the adjustor

screws evenly while moving the handle up and

down. Adjust so that there is no free play, yet any

binding anywhere in its range of travel. Then

retighten the lock nuts.

Periodically check, lubricate, and adjust as need-

ed.

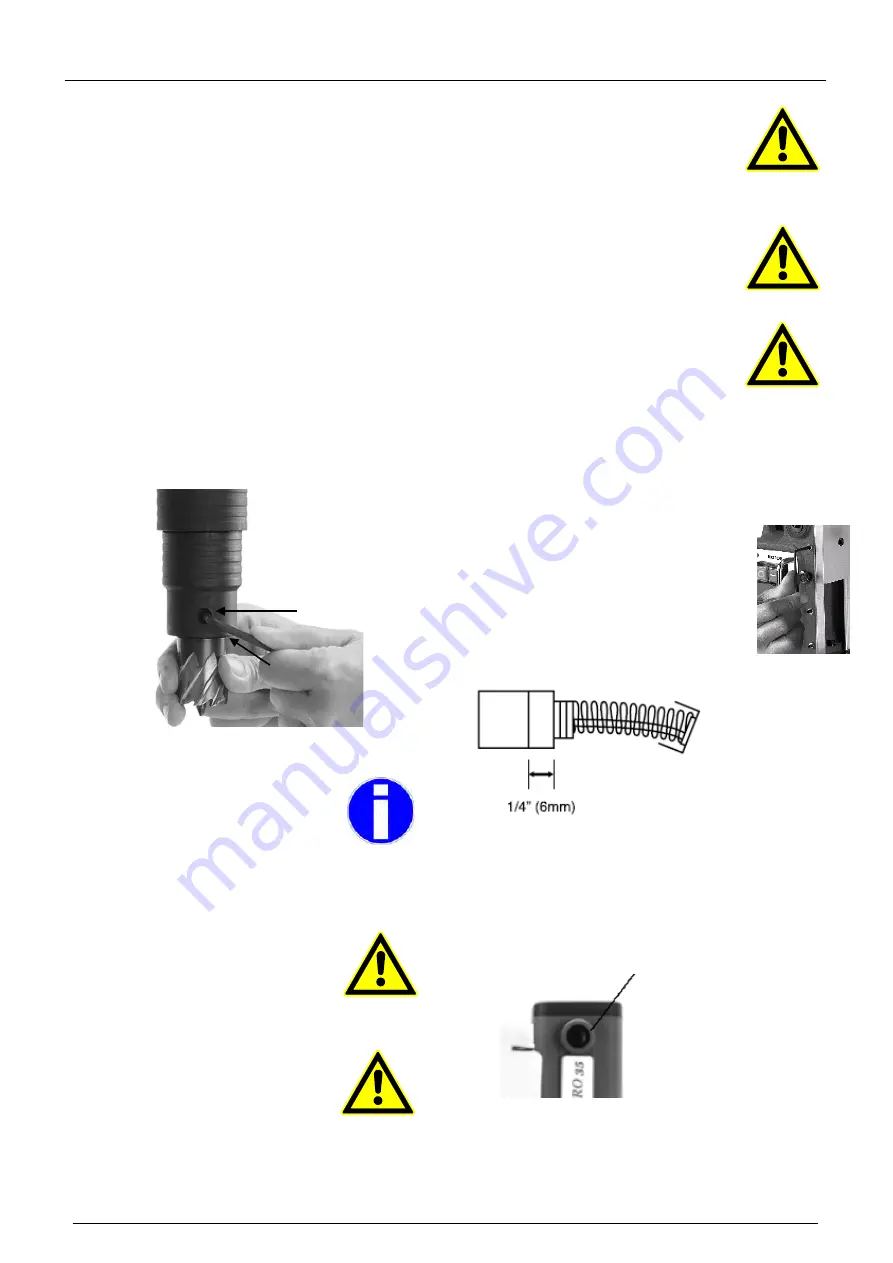

6.2.3 Carbon Brushes

The carbon brushes are a normal wearing part and must be re-

placed when they reach their wear limit.

Caution: Always replace the brushes as a pair.

To replace: simply remove the brush caps and withdraw the old

brushes. Replace with new brushes ensuring that they align properly

and slide freely. Then replace the brush caps. (See figure)

Always entrust all repairs to an authorized service agent.

Always entrust all repairs to an authorized service agent.

Brush cap

1

2