Section III: Maintenance

Page 55

5-376-000102

REV. 1 - 07/10

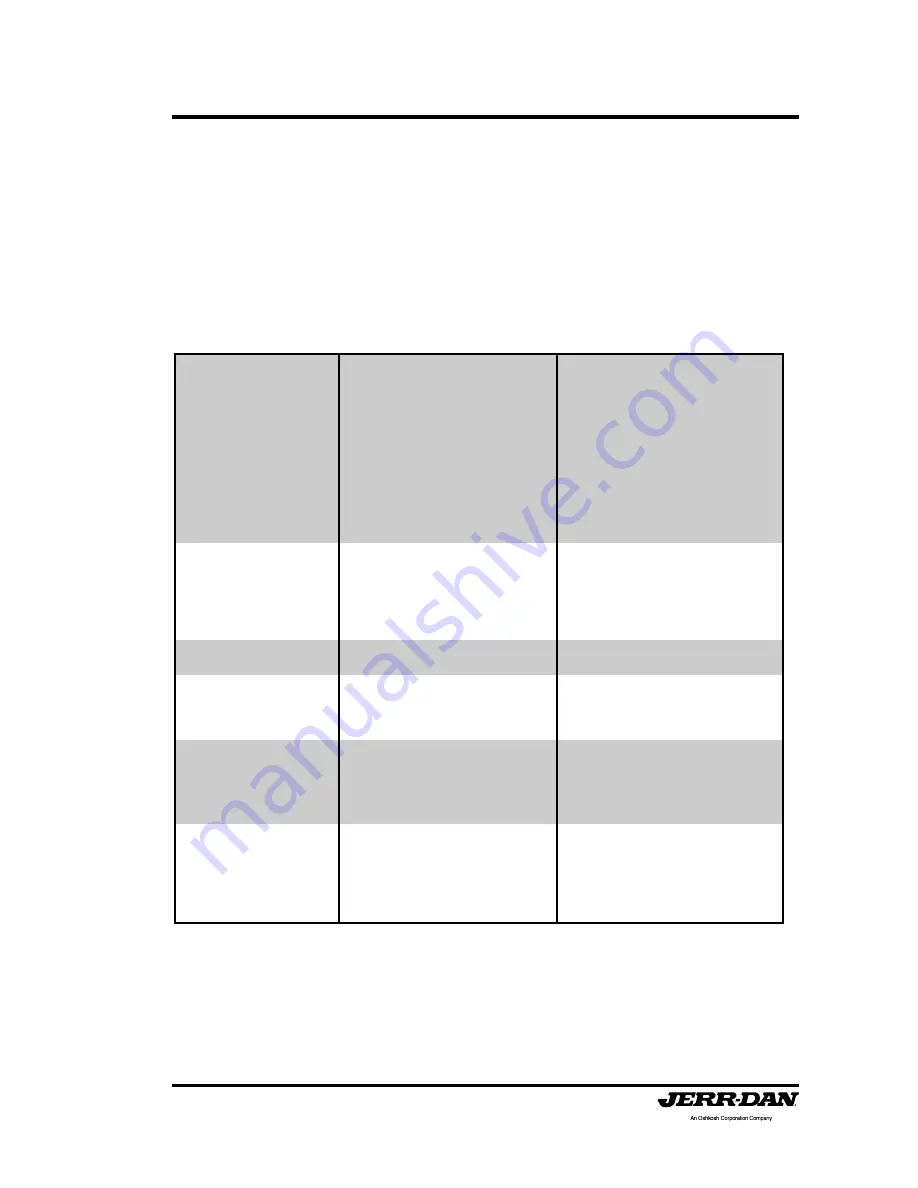

TROUBLE SHOOTING

You probably won’t require anything but preventive maintenance to keep

your MPL running, however, the following chart should help you isolate

and correct minor problems if they occur with use. Any service work on

the hydraulic system should be performed by qualified mechanics.

HYDRAULIC SYSTEM

Problem

Cause

Solution

Slow operation

a. Low engine RPM

a. Speed up engine

b. Low oil level

b. Check dipstick and fill with

the specified oil

c. Blocked or restricted

c. Inspect: remove blockage

hoses

d. Dirty hydraulic oil

d. Drain, flush and refill with

clean oil, replace filter

e. Hydraulic pump worn

e. Rebuild or replace

f . Clutch Pump belt slipping

f . Tighten or Replace belt

Valve Solenoid(s)

a. Broken centering spring

a. Inspect, clean or replace

sticking or frozen

or clogged with foreign

material

b. Low Amperage/Voltage

b. Check Amperage/Voltage

at Solenoid

Valve leaks

a. Defective seals

a. Replace

Cylinder leaks

a. Defective seals or rods

a. Inspect and replace

b. Dirty or Defective

b. Clean or Replace

CounterBalance Valve

CounterBalance Valve

Erratic cylinder

a. Air in the system

a. Cycle hydraulic system 10

function

to 15 times to remove air

b. Defective pump

b. Replace if necessary

(pulsating)

Remote hand

a. Electric power turned off

a. Turn on CONTROL power

controller fails to

switch in cab

respond

b. Not plugged in

b. Check plug connection

c. Faulty Remote Hand

c. Use Manual Controls

Controller

at Rear of Body