10

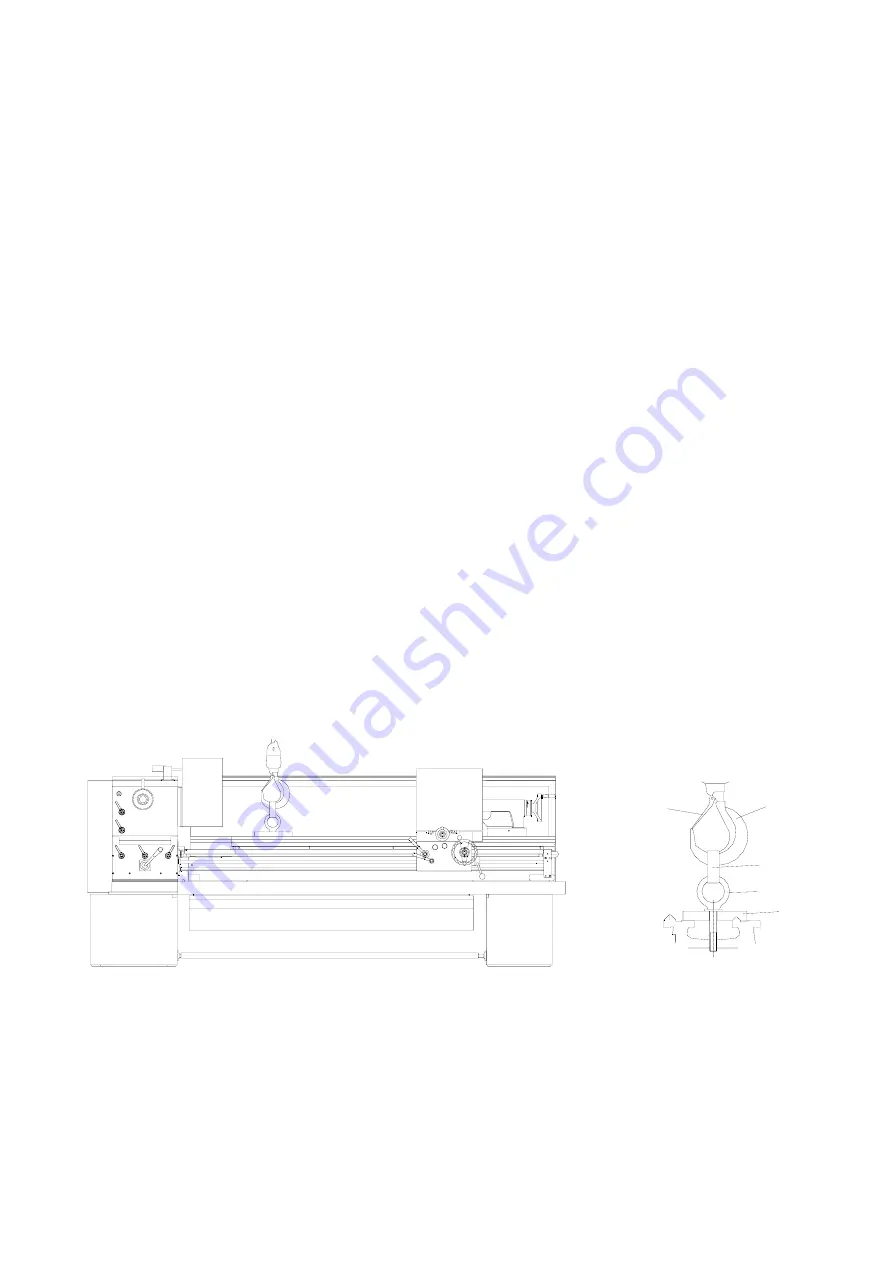

LlFTING

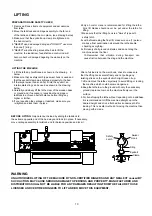

PREPARATION AND SAFETY CHECK

1 .Remove all loose items of equipment and accessories

from lathe.

2.

Move the tailstock and carriage assembly to the far end

of the lathe and clamp them in place, (see drawing below)

3.

Make sure that the eyebolt and clamp are tightened on

the bed correctly.

4.

"NEVER" used a damaged sling and "DO-NOT" use more

than one(1) sling.

5.

"NEVER" wrap the sling around the bed to lift the

machine; the leadscrew, feedshaft and control rod will

become bent or damaged nagating the warranty on the

machine.

6.0nly a hoist or crane is recommended for lifting the lathe.

Fork lift blades should never be put under the lathe for

lifting.

7.

Make sure that the lifting hook is a "Swivel" type with

safety latch.

8.

Just before making the final lift, make sure one (1) person

makes a final examination all around the lathe double

checking everything.

9.

Lift cleanly of all ground obstacles and do not drag the

machine across the floor.

10.Remember that vibration during transport can

cause friction between the sling and the machine.

LIFTING THE MACHINE

1 .Lift the lathe by hoist/crane as shown in the drawing

below.

2.Make sure that a safety-latch type swivel hook is used and

that the eyebolt clamp was tightened properly to the bed.

3.If the larger swivel hook can not fit into the eyebolt, an

intermediate sling can be used as shown in the drawing

below.

4.Carefully and slowly lift the lathe clear of the wooden base

or ground and, if necessary, reposition the carriage or

tailstock to achieve a better balance before lifting any

higher or further.

5.If you reposition the carriage or tailstock, make sure you

re-tighten and lock them in place.

6.

After a full load is on the main hook, check to make sure

that the lifting hook swivels freely and not putting any

twisting stress on the eyebolt which might loosen it up.

7.

Lift and move the lathe very slowly to avoid tilting or rocking

the machine which could become dangerous.

8.

Keep the lathe low to the ground with only the necessary

ground clearance to move the machine freely over the

surface.

9.

For transhipping the lathe without repacking onto a skidbase,

it is recommended to lift the machine straight up to the

desired height and drive a flat bed truck underneath it for

loading. This is a safer method of moving the machine than

moving with a crane.

BEFORE LIFTING:

Help balance the load by sliding the tailstock to

the extreme opposite end of the bed ways and lock it in place. If necessary,

move carriage assembly to tailstock end for balance position and lock it.

Safety

Latch

Swivel

Hook

Sling

Eyebolt

Clamp

WARNING

UNAUTHORIZED LIFTING OF THE MACHINE BY NON-CERTIFIED RIGGERS AND ANY NEGLECT caused BY

SUCH ACTION MAY CAUSE SERIOUS DAMAGE TO PERSONS AND PROPERTY. MANUFACTURER AND

DISTRIBUTORS SHALL NOT BE LIABLE FOR ANY DAMAGES RESULTING FROM THE FAILURE TO USE

LICENSED AND CERTIFIED RIGGERS TO LIFT AND/OR MOVE THIS EQUIPMENT.