24

LUBRICATION CHECKS

Before operating the machine and trouble-free operation keep the

lathe clean and regularly lubricated are very important.

The oil bath designed headstock, feed gearbox and apron; the self-

splash lubricated all the spindle, shafts, gears and bearing. The

reservoirs contained oil should be reach to the level mark on oil

sight windows. The headstock and feed gearbox recommend with

ISO V.G. 32 or equivalent. The apron recommends with ISO V.G.68

or equivalent.

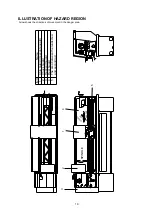

To replenish or exchange the oil in headstock and feed gear box by

open the end gear cover; to replenish the oil from both filler elbows

(F) and to drain the oil from both drain plug (D) (Fig. 6). For the

apron, to replenish the oil from the oil cap on saddle and to drain the

oil from drain plug at the bottom of apron.

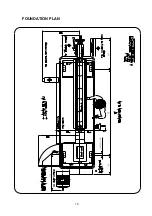

To the slideways, leadscrew, feed rod and all the oilers located on

saddle, cross slide, top slide, tailstock and end bracket etc. Apply an

oil can to all the points shown on lubrication chart which require

daily oiling. Use light machine oil or way lubricants.

DO NOT MIX LUBRICANTS: When alternative lubricants are to be

used, the oil reservoir should be drained and flushed out before

refilling with new oil.

NOTE: RECOMMENDS AN OIL CHANGE IN THE HEADSTOCK,

FEED GEARBOX & APRON WITHIN THE FIRST 3 MONTHS FOR

A NEW MACHINE.