34

ADJUSTMENT

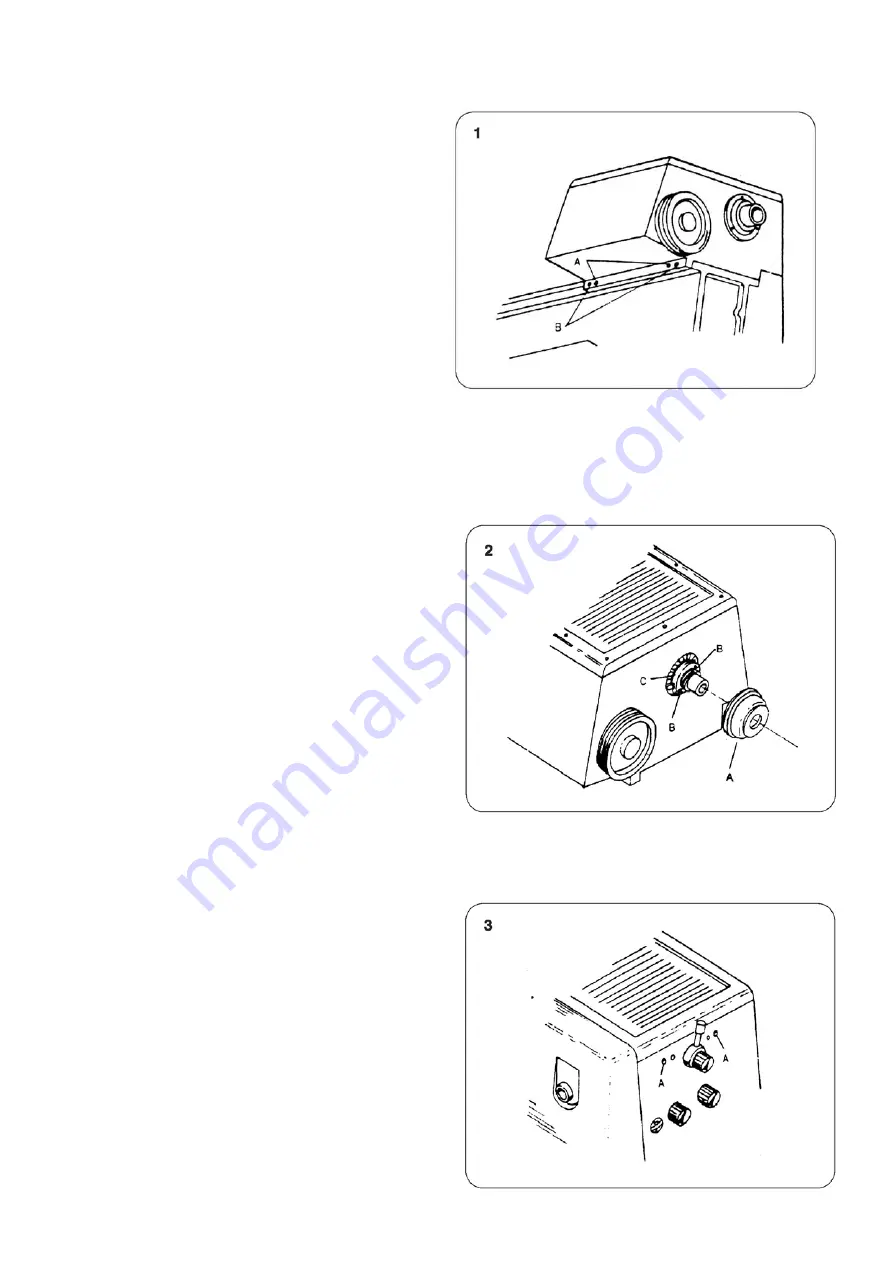

1.ADJUSTMENT OF HEADSTOCK

When the centerline of main spindle not alignment with the

bedway, it could be adjusted by fixing bolts (A) and adjusting

bolts (B) shown as follow figure. If the headstock is needed to

move forward, loose the fixing bolt (B), fasten the adjusting

bolts (B) to proper position, then, fasten the fixing bolts (A)

again. If the headstock is needed to move backward, loose the

adjusting bolts (B), fasten the fixing bolts (A) to proper position,

then, fasten the adjusting bolts (B) again.

Beware to release four fixed screw of the headstock to the bed

before adjustment and re-tighten it after adjustment.

2.SPINDLE BEARING ADJUSTMENT

When we find the spindle bearings are too tight or loose open

the rear bearing cover (A) and loose the set screw (B) on the

spindle bearing thrust nut (C) and then adjust the thrust nut by

loosing or fastening. The proper adjustment is finished by

fastening the set screw again.

3.STRENGTH ADJUSTMENT OF KNOB POSITIONING

SET SPRINGS

When changing speed of Headstock spindle, sometimes you

could find the knob cannot be operated smoothly and

accurately. The correction for this trouble is to loose or fasten

the cap screw (A) to keep the internal spring tension properly..