INSTALLING YOUR STOCK GUIDES TO A ROUTER TABLE OR TABLE SAW

WITH AN UP TOP 1/4" T-SLOT

There is an additional set of eight (8) counter bored holes for use with the ¼”-20 Low Head Cap Screws

and the ¼”-20 square nuts, but only one row will line up with your T-Slot. We have included four

screws and four square nuts for use with these. Because there are two rows of these holes, it does not

matter which side faces the front of your fence. To install on a top mounted T-Slot, slide the four square

nuts roughly into position and then using the 1/8” hex key, screw in the four ¼”-20 Low Head Cap

Screws through the track and into the nuts. Slide the track for best placement on both sides of your

router bit or table saw blade and tighten these screws. Loosen the track knobs on each stock guide

enough to allow it to slide onto the track. Position the stock guide and re-tighten the track knobs.

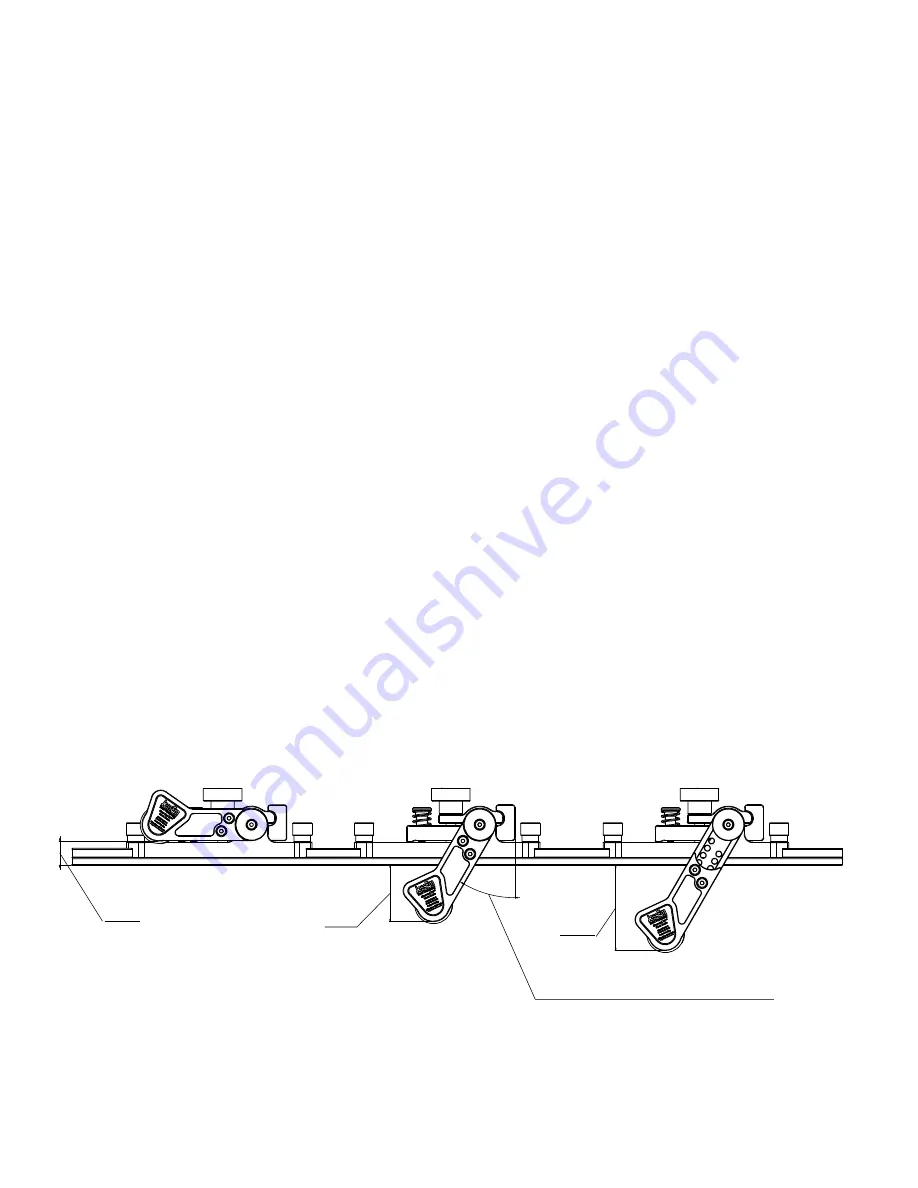

ADJUSTING THE LENGTH OF THE ROLLER ARM ON YOUR CLEAR-CUT STOCK GUIDES

The roller arm is adjustable to five different positions and can be extended 1.3" from the fully retracted

position it is shipped in. On the most common table saw fences the fully retracted position as it is

shipped is the correct setting. On some higher fences or on a router table fence which is typically higher

than a table saw fence the stock guides need to be extended. The ideal position for cutting with your

stock guides is for the roller arm to be at approximately a 30 degree angle from vertical or greater. (See

Figure #3

) They will work at less of an angle but will apply more lifting force to the fence in the case of

kick back. Once the length of the roller arm is set thicker stock will be cut with the stock guides at a

greater angle. If your stock guides need to be adjusted to reach your table saw or router table surface

then using the 1/8” hex key provided remove the two ¼”-20 X ½” Low Head Cap Screws on the roller

arm and adjust the arm outward till the desired setting is reached. Then re-insert and tighten these

screws just previously removed. Once they are adjusted the ideal angle of the roller arm should be

roughly 30 degrees from vertical when touching or close to your table surface or the minimum stock

thickness you would cut with your saw.

MAXIMUM STOCK

THICKNESS ABOVE

MOUNTING SURFACE

MAXIMUM TRAVEL

BELOW MOUNTING

SURFACE ARM IN

RETRACTED POSITION

MAXIMUM TRAVEL

BELOW MOUNTING

SURFACE ARM IN

EXTENDED POSITION

3.341

2.215

0.921

30°

RECOMMENDED MINIMUM ANGLE

FIGURE #3

7.