LOCKING THE TABLE SLIDE POSITION

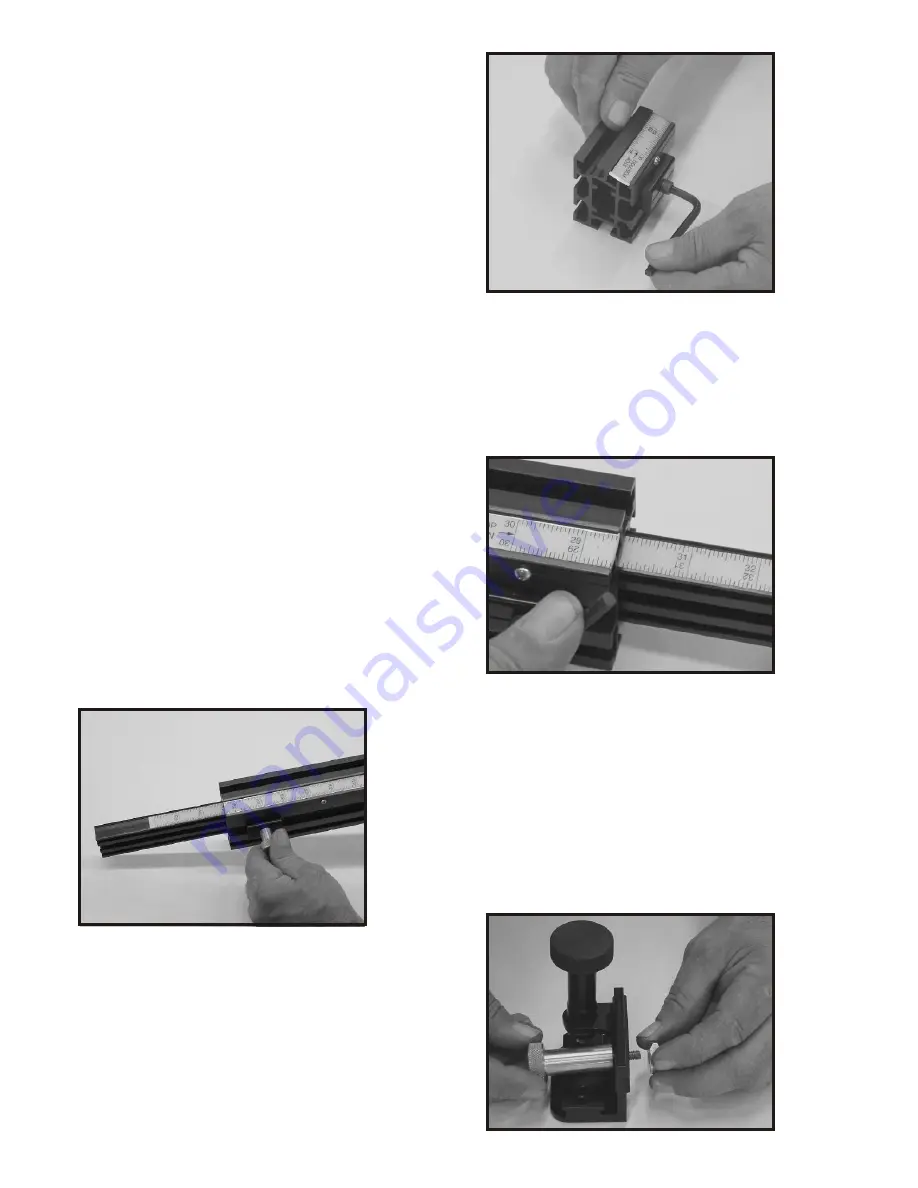

1. The table slide has a spring loaded, shot

pin type, locking knob under the front end of

the lower carriage assembly (Fig. 12).

2. Pull down and twist the knurled knob

until the “T” knob slides into the groove on

the shaft to engage the shot pin. To release

the shot pin, pull and twist the knurled knob

so that the “T” knob sits on the shaft

perpendicular to the groove and disengages

the shot pin.

3. There are four stops for locking the table

slide in a fixed position. You can position the

table slide to be flush with the rear of the

lower carriage assembly, or flush with the

front of the carriage assembly, or centered

on the carriage assembly, or positioned with

the table slide at full extension to the front of

the saw for safely holding the table slide in a

fixed position while placing the workpiece

onto the table slide in preparation for cutting.

WARNING! - Do not sit on, or lean on the

sliding table at any time and especially not

when the table slide is at full extension. Do

not overload the sliding table with heavy

objects or a heavy workpiece at any time as

you may risk causing the table saw to tip

over and cause damage to the machine

and/or injury to the operator.

ASSEMBLING THE FENCE

1. Take the miter fence (item #4 from the

parts list on page 2) and observe that inside

the fence extrusion is the extension rod. Hold

the fence level and being careful not to let

the extension rod slide out and fall on the

floor, loosen the extension locking knob and

slide the extension rod out (Fig. 13) to allow

the attaching of the fence extension block.

FIG. 13

FIG. 14

2. Take the fence extension block (item #3

from the parts list on page 2) and using the

3/16” hex wrench, loosen the 1/4”-20 cap

screw on the extension block to loosen the

internal nut sufficiently to allow insertion

onto the fence extension rod (Fig. 14).

FIG. 15

FIG. 16

3. Slide the fence extension rod into the

extension block ensuring the internal nut is

aligned with the T-slot on the extension rod.

Position the extension block so the inner

edge of the extension block lines up with the

“red” line at the 30 inch mark on the scale

(Fig. 15). Re-tighten the cap screw on the

extension block clamping nut to hold it in this

position.