12

6. If drum does not contact gauge equally on both

ends of drum, alignment is needed.

7.4.1

Performing drum alignment

To align conveyor table with drum:

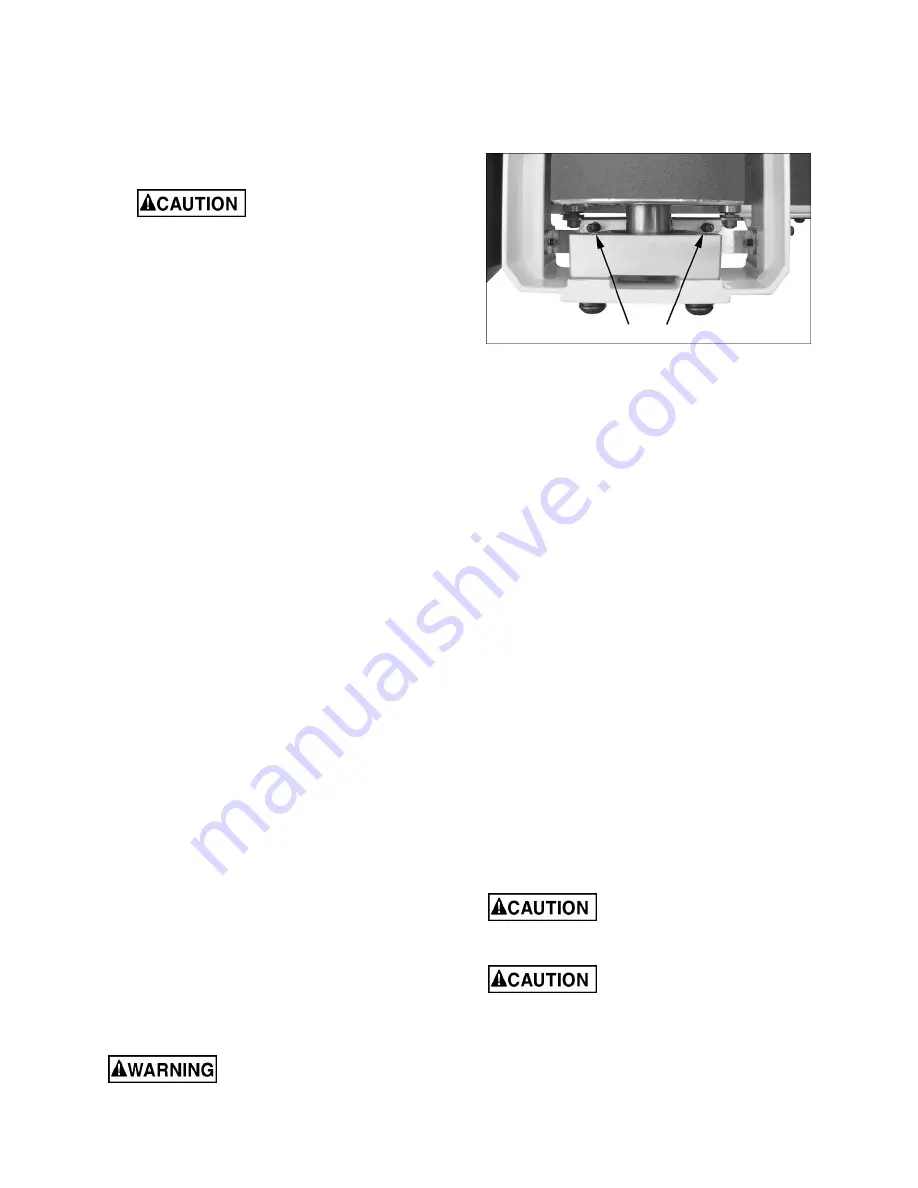

1. Loosen both table locking screws (C, Figure 7-

3) with 5mm hex wrench.

Loosen both table locking

screws before adjusting drum alignment.

Failure to comply may cause damage to

conveyor table.

2. To

raise

outboard end of table, loosen lock nut

(E, Figure 7-3) and rotate knurled nut (D, Figure

7-3) clockwise.

3. To

lower

outboard end of table, rotate knurled

nut (D) counterclockwise, and tighten lock nut

(E).

4. Verify setting using the gauge. Make further

adjustments using knurled nut as needed.

5. Retighten table lock screws (C).

7.4.2

Fine-tuning drum alignment

Note: This is an operational test for sanding boards

wider than the drum. Perform this procedure only

after you have become familiar with sander

operation.

When sanding boards wider than the drum, table

alignment is critical and table must be adjusted

exactly level to slightly lower on the outboard end.

This will prevent any ridges from developing in the

stock. Always check this on a piece of scrap wood,

as follows, before sanding the work piece.

1. Run a piece of scrap wood approximately 6”

wide by 18 to 20” long through the sander

sideways so that end of board extends past

outboard side of drum.

2. Without changing drum height, rotate board

180° and sand the same side.

3. If a ridge is visible where the drum overlaps,

lower table at outboard end (see sect. 7.4.1).

4. Repeat this process until the ridge is eliminated

and entire board is sanded.

Note:

When sanding narrow stock (less than 10”),

return conveyor table to parallel position.

7.5

Tension roller adjustment

The infeed and outfeed rollers are tensioned to

provide downward pressure on the workpiece to

prevent slippage on the feed conveyor. Tension

rollers have been set by the manufacturer, but

should be inspected and may require adjustment as

the sander receives use.

Improperly adjusted tension

rollers (i.e. those set too high, rendering them

non-functional) could allow kickback of pieces

being sanded.

Tension roller pressure may be increased or

decreased by turning the screws on the tension

roller brackets (Figure 7-4) at each end of drum..

Figure 7-4: tension adjustment screws

Too much tension roller pressure can result in a

“snipe” mark, which is a visible line running across

the width of the board and located approximately 2-

1/4” from end of board.

If snipe occurs on the leading end of board, adjust

outfeed tension roller. If the snipe occurs on trailing

end of board, adjust infeed tension roller.

8.0

Operations

Before using your drum sander, review the previous

sections on initial set-up and adjustment. Before

operating, make sure an abrasive strip is mounted

and a proper dust collection system is connected.

8.1

Basic Operating Procedure

1. Establish depth of cut.

2. Start dust collection system.

3. Start sanding drum (with control panel switch,

Figure 8-1).

4. Start conveyor and select feed rate (with control

panel dial, Figure 8-1).

5. Feed stock through machine.

To feed stock through the sander, rest and hold

board to be sanded on conveyor belt, allowing

conveyor belt to carry board into drum. Once stock

is halfway through, reposition yourself to outfeed

side of machine to receive and control board as it

exits.

Board will be forced down

against conveyor table as it begins feeding,

causing pinching hazard. Keep fingers away.

Do not open drum hood until

drum comes to a complete stop.