11

Dust Cover

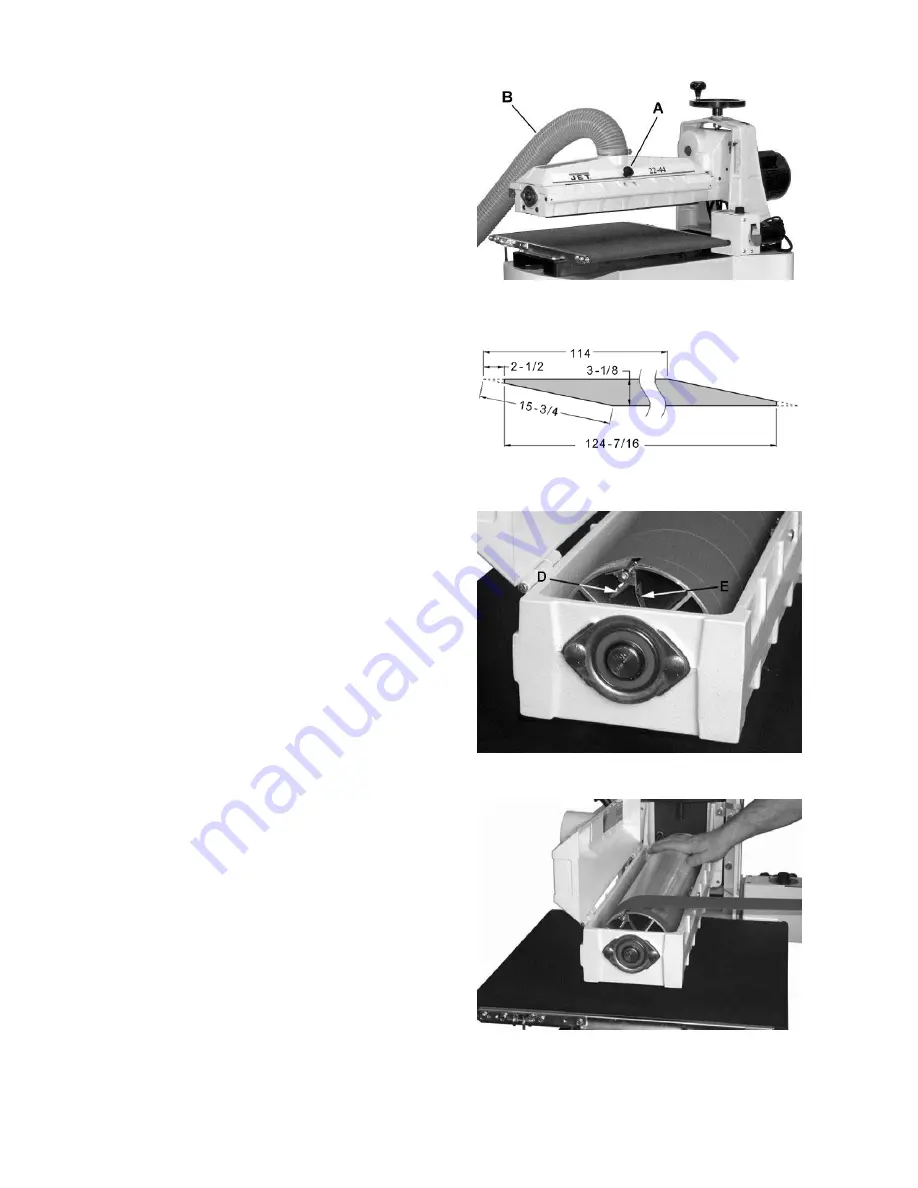

To open the dust cover, push in on the

knob

(A, Fig. 7) and lift. The latch can be adjusted using

the screw behind it.

Dust Collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The

22-44OSC is equipped with a 4” dust collection port

at the top of the dust cover. It is designed to be

used with standard 4”

dust collection hose

(B,

Fig.

7) connected to a high volume dust

collector (minimum 500 CFM) as shown.

JET offers a variety of Dust Collectors and Air

Filtration Units. Contact your local distributor for

more information.

Installing Abrasives

An 80-grit, 3-1/8” wide abrasive strip is already

installed on the drum of your sander.

Proper attachment of the abrasive strip to the drum

is critical to achieving top performance from your

drum sander. Abrasive strips do not have to be pre-

measured. The end of the roll is first tapered and

attached to the left (outboard) side of the drum.

Then the strip is wrapped around the drum, and the

second taper is made for attachment to the right

(inboard) side of the drum.

Note:

You can use the original abrasive strip

mounted to the drum as a template for cutting your

own strips.

1. Mark and cut a taper at one end of the roll as

shown in Figure 8. Because the tapered end

should use all of the left (outboard) slot width,

its end must be trimmed back as shown.

2. Raise the fastener lever (D, Fig. 9) on the

outboard end of drum, and insert the tapered

end of the abrasive (E, Fig. 9) so that it uses

most of the width of the slot. Release the

fastener lever to securely hold the strip end to

the fastener.

3. Begin wrapping the strip around the drum. The

tapered edge of the strip end should follow the

edge of the drum.

4. Continue to wrap the abrasive in a spiral

fashion by rotating the drum with one hand and

guiding the strip with the other (Figure 10).

Successive windings of the strip should be

flush with previous windings

without any

overlap.

Figure 7

Figure 8

Figure 9

Figure 10