8

Grit 80:

Surfacing, light dimensioning, most

popular grade.

Grits 100 and 120:

Surfacing and finishing.

Grits 150, 180 and 220:

Finish sanding only.

7.3 Cleaning drum abrasives

Regularly clean the abrasive strips on

the drum with the supplied cleaning

stick.

This will remove the deposits and help

extend sandpaper life.

Warning:

Always wear tight fitting clothes

and eye protection. Keep alert

during this operation to avoid

injury.

Operate the sanding drum with the

oszillation turned off and with the dust

cover open.

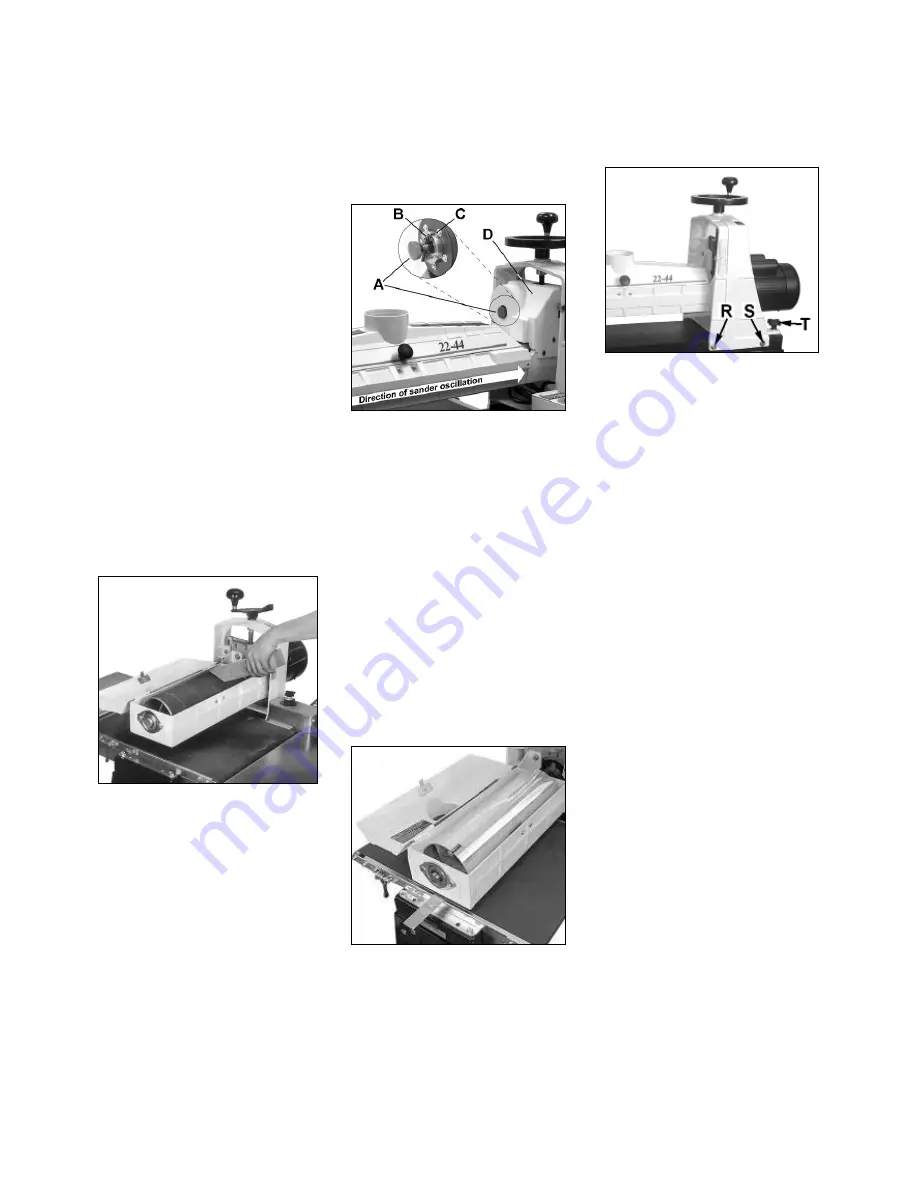

Hold the cleaning stick (Fig 13)

against the rotating drum and move it

along the drum surface.

It is good procedure to use a shop

brush to remove any cleaning stick

crumbs before resuming sanding

operation.

Fig 13

Abrasive life can also be increased by

reversing the trailing and starting end

of the strip.

This will provide a fresh set of cutting

edges on the abrasive.

7.4 Oscillaton

The 22-44OSC sander can be

operated as a simple linear sander or

as an oscillating sander.

Before changing the sanding

operation, the sander must be turned

off.

Linear Sanding:

Before changing the sanding

operation, the sander must be turned

off.

For linear sanding mode, pull out the

oscillator switch (A, Fig 14).

Fig 14

Oscillating Sanding:

Before changing the sanding

operation, the sander must be turned

off.

For oscillating sanding, push in the

oscillator switch (A, Fig 14).

Rotate the oscillator switch until the

clutch (B, C) engages.

Operating Note:

For best results, the feed rate must be

set to maximum when in the

oscillation mode.

7.5 Drum alignment

Disconnect the machine from the

power source (pull mains plug).

Remove the abrasive strip from the

drum and use a straight edge or ruler

(Fig 15) as a thickness gauge.

Fig 15

Insert the gauge between the drum

and the conveyor bed and inspect for

parallel contact.

To align the drum, loosen the four hex

bolts (R and S, Fig 16).

This allows the entire drum carriage to

pivot on two bolts (R).

Fig 16

Align the drum by turning the fine tune

adjustment knob (T).

When drum is parallel tighten the four

hex bolts.

Fine tuning drum alignment:

For optimum sanding of boards wider

than the drum, the drum alignment is

critical and must be exactly level to

slightly high on the outboard end.

Turn the board and without changing

the drum height, sand the other end of

the board. If a ridge is visible due to

drum overlap, loosen the four hex

bolts (R+S, Fig 16) and raise the

outboard end of the drum by turning

the fine adjustment knob (T) slightly

clockwise and tighten the four hex

bolts.

Important:

Only turn the fine tune adjustment

knob (T, Fig 16) when all four hex

bolts (R and S) are loose.

7.6 Conveyor belt adjustment

To align the tension of the conveyor

belt, first adjust the take-up screw nut

(U, Fig 16) on both sides of the

conveyor to obtain approximately

equal tension.