permanently lubricated ball bearings. The drum assembly is

mounted in a truss-like carriage arm for superior strength and

rigidity. This system also makes aligning the drum to the table

surface easy. That means consistent performance with minimal

adjusting by the operator.

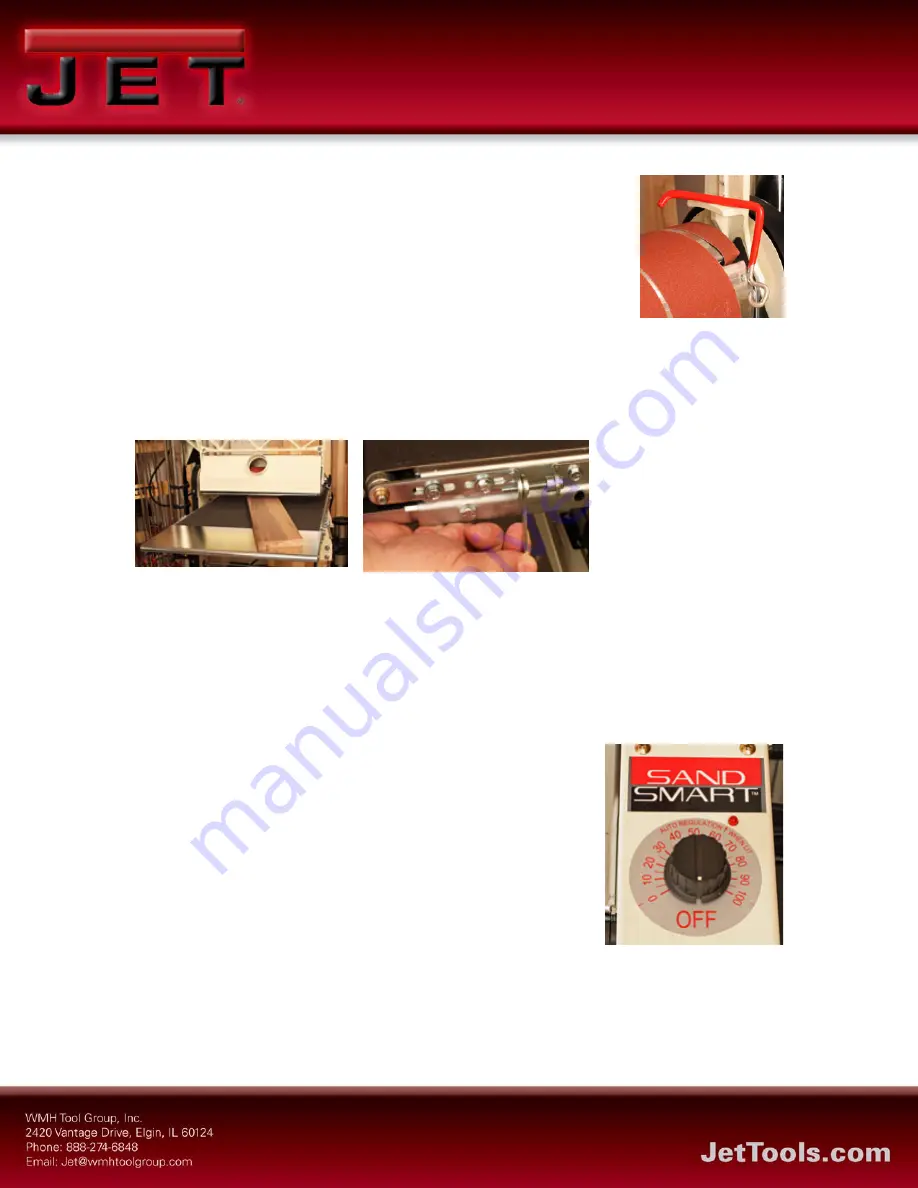

Our special Tuf Tool

makes changing abrasive

strips easier.

The drum is equipped with patented abrasive take-up fasteners that

make changing the abrasive strips fast and easy. We also include

our exclusive Tuf Tool

™

that makes operating the take-up

fasteners a no-strain event.

Table and Feed

The generous 23”-wide

by 30 ¾”-long

conveyor platform is

augmented by the

included 10”-deep by

24”-wide steel

extension tables. That

provides 51” of overall

support that handles

the big jobs with ease.

The expansive conveyor surface is expanded even further with the included steel

extension tables. (left) Easy to use conveyor belt tension adjusters (right) even have

the necessary wrench captured on the bolt!

The conveyor belt features easy to use tension and tracking adjusters. Each adjuster has a

built-in wrench captured on the threaded shaft so you never have to look for a tool to

make a small adjustment! Plus, our patented conveyor belt TRACKERS™ dramatically

reduce the need for manual belt adjustments.

Our exclusive SandSmart

circuitry protects against

overloads by automatically

slowing the feed rate to prevent

damage to the wood, abrasive

strip or motor.

The specially designed, no-give conveyor belt moves over a

precision flattened steel bed so the wood is always on a true

surface. That means super smooth, consistent sanding for the

best possible results.

The JET 22-44 Pro-3 Drum Sander uses a separate feed

motor to drive the conveyor belt. That insures consistency but

also allowed us to develop our EXCLUSIVE SandSmart™

variable-feed control system. This infinitely variable feed rate

control operates between 0 to 10 feet per minute so you can

use the best rate for the job. The SandSmart

™

technology

also prevents straining the machine by sensing the load on the

conveyor and automatically reducing the feed rate to help

prevent burning of the wood or the abrasive.