30

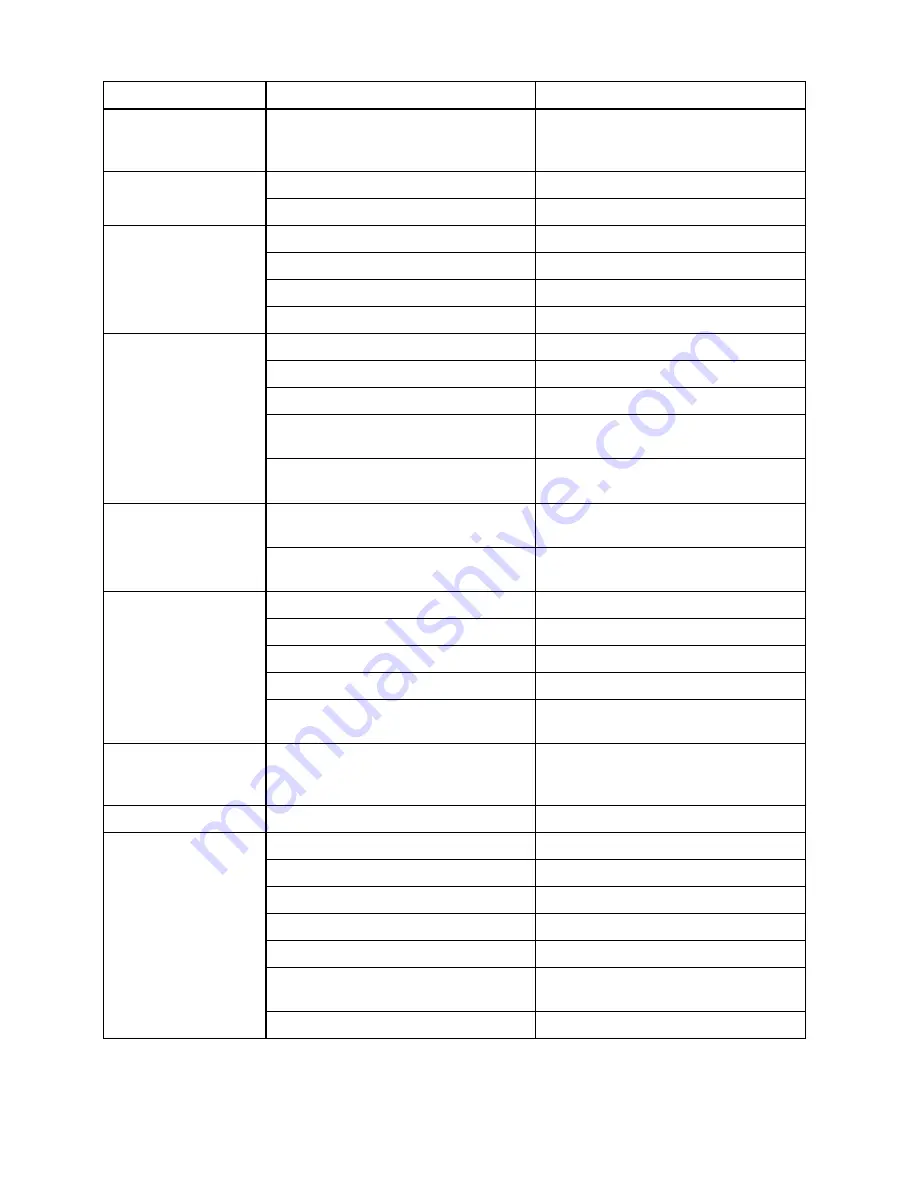

Troubleshooting – Mechanical Problems

Trouble Probable

Cause

Remedy

Conveyor belt does

not move, or runs

intermittently.

Shaft coupling (#11, page 38) is loose

or unattached.

Align the shaft flats of the gear motor

and the drive roller and tighten the

shaft-coupling setscrews.

Conveyor belt slips on

drive roller.

Improper conveyor belt tension.

Adjust belt tension.

Excessive depth of cut or feed rate.

Reduce depth of cut; reduce feed rate.

Board slips on

conveyor belt.

Tension rollers too high.

Lower tension rollers (see page 20).

Excessive feed rate.

Reduce feed rate.

Dirty or worn conveyor belt.

Replace conveyor belt.

Abrasive improperly wrapped.

See

Installing Abrasives

, pages 12-13.

Conveyor belt tracks

to one side, or

oscillates from side to

side.

Conveyor belt out of adjustment.

Readjust conveyor belt; see page 19.

Drive or driven roller needs adjusting.

Readjust; see page 19.

Conveyor belt worn or defective.

Replace conveyor belt; see page 20.

Drive roller worn, bent, or varies in

diameter side to side.

Replace drive roller.

Roller bushings elongated due to

excessive wear.

Replace bushings.

Abrasive strip is loose.

Strip caught on inside edge of slot, or

on inboard side of drum.

Re-adjust the strip end in the slot

and/or trim the abrasive edge.

Strip not cut properly.

Re-cut and re-install abrasive strip.

See pages 12 and 13.

Abrasive loads up

prematurely.

Excessive depth of cut.

Reduce depth of cut.

Excessive feed rate.

Reduce feed rate.

Inadequate dust collection.

Increase airflow at dust port.

Inadequate abrasive.

Use an open-coat abrasive.

Stock fed at 90° angle to drum.

Angle stock 60° if possible to avoid

resin line buildup.

Table height

adjustment works

improperly.

Improper adjustment of height control.

Readjust height control. See pages 15

and 16.

Drum drive v-belt slips. Improper v-belt tension.

Increase tension.

Knocking sound while

running.

Bearing(s) out of alignment.

Re-align bearings; see page 22.

V-belt worn.

Replace v-belt; see page 22.

Dust in drum.

Remove material inside drum.

Pulley wobbling or out of round.

Replace pulley.

Set-screws loose in pulley or bearing.

Re-tighten set-screws.

Abrasive fastener on drum loose

(without abrasive strip in place).

Insert abrasive strip, or replace

fastener.

Drum bearing(s) worn.

Replace drum bearing(s).

Summary of Contents for 22-44 Pro-3

Page 35: ...35 Stand Assembly...

Page 37: ...37 Drum Head Assembly...