17

10.0

Lathe Accessories

10.1

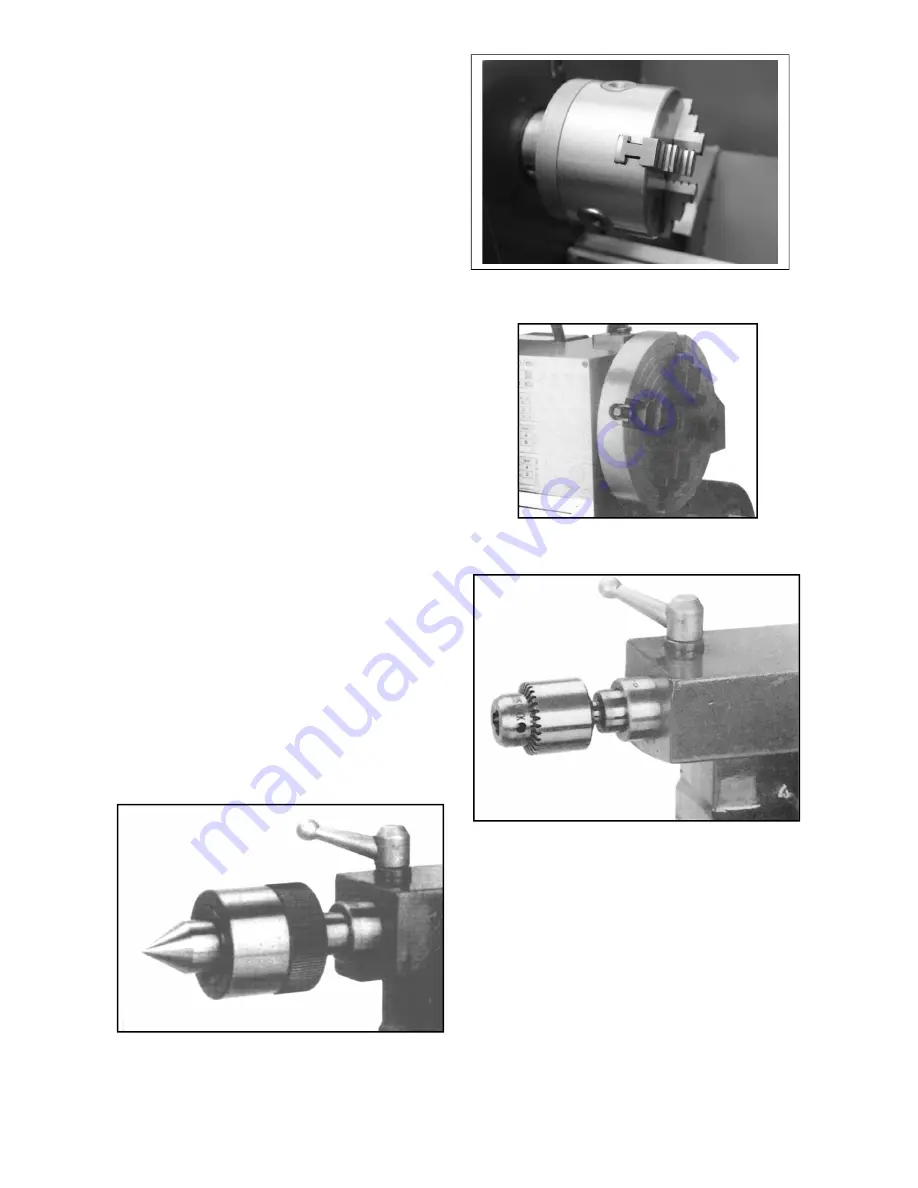

Three jaw universal lathe chuck

Using this universal chuck (Figure 21), round,

triangular, square, hexagonal, octagonal, and

twelve-cornered stock may be clamped.

Note:

New lathes have very tight fitting jaws. This is

necessary to ensure accurate clamping and long

service life. With repeated opening and closing, the

jaws adjust automatically and their operation

becomes progressively smoother.

10.2

Four jaw independent lathe

chuck

This special chuck (Figure 22) has four

independently adjustable chuck jaws. These permit

the holding of asymmetrical pieces and enable the

accurate set-up of cylindrical pieces.

10.3

Drill chuck (optional)

Use the drill chuck to hold centering drills and twist

drills in the tailstock (Figure 23).

10.4

Morse taper arbor (optional)

An arbor is necessary for mounting the drill chuck in

the tailstock. It has a No. 2 Morse Taper (Figure 23).

10.5

Live center (optional)

The live center is mounted in ball bearings (Figure

24). Its use is highly recommended for turning at

speeds in excess of 600 RPM.

Figure 24

Figure 21

Figure 22

Figure 23

Summary of Contents for 321378

Page 25: ...25 13 2 1 Drive Belt Assembly Exploded View...

Page 29: ...29 13 5 1 Electrical Exploded View...

Page 32: ...32 13 7 1 Gear Box Exploded View...

Page 35: ...35 13 8 1 Apron I Exploded View...

Page 38: ...38 13 10 2 Saddle and Cross Slide Exploded View...

Page 40: ...40 13 11 1 Compound Slide Exploded View...

Page 42: ...42 13 12 1 Tailstock Exploded View...

Page 46: ...46 13 15 1 BD 919 Bed Assembly Exploded View...

Page 48: ...48 13 16 1 BDB 929 Bed Assembly Exploded View...

Page 54: ...54 15 0 Speed and threading charts...

Page 56: ...56 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...