12

Belt Tracking Adjustment

1. Connect the machine to the power source.

One time quickly turn the machine “ON” and

“OFF”. This will allow you to view the belt’s

tendency to run down the middle, to the right,

or to the left. The belt should run centered on

the sanding drums. Do not let the belt run off

the drum to the right or left. The belt will tear

when it contacts parts of the machine.

2. Disconnect the machine from the power

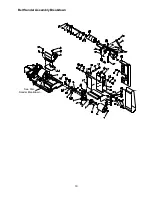

source. Move the tension handle (A, Fig. 10)

to the “Loosen” position. Center the belt again

and move the handle to the “Tighten” position.

3. Release the tracking lock (B, Fig. 10) by

pulling up on the handle. If the beIt has a

tendency to track left of center, turn the

adjusting knob (C, Fig. 10) counterclockwise

until the belt tracks in the center.

4. If the belt has a tendency to track right of

center, turn the adjusting knob clockwise until

the belt tracks in the center.

5. Secure the tracking lock by pushing the lever

down. Note: when tightening the tracking lock

the belt may tend to move to the left.

6. Fine tune tracking by turning the adjusting

knob (C, Fig. 10).

Note:

To prevent the sanding belt from stretching

and to prolong belt life, remove tension from the

belt if not using for a long period of time.

Disc Table Adjustment

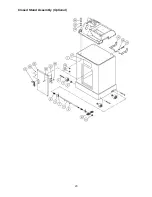

1. Disconnect machine from the power source.

2. Place a square on the table next to the

sanding disc (Figure 11). Loosen locking

handle and move the table to 90°. Tighten

locking handles.

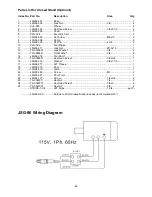

3. Place a combination square (A, Fig. 12) in the

miter gauge slot (B, Fig. 12) and check the

distance from the slot to the edge of the

sanding disc. Slide the square along the slot to

the other end of the disc and check the

distance. The distances should be equal to

ensure that the miter gauge travels parallel to

the disc.

Figure 10

Figure 11

Figure 12