13

5. See “Adjustments” section for further

instruction on adjusting the disc table.

Belt Table

1. Loosen the sanding platen lock screw (E,

Figure 13) with a 6mm hex wrench, and tilt the

belt arm to a vertical position. Re-tighten the

lock screw.

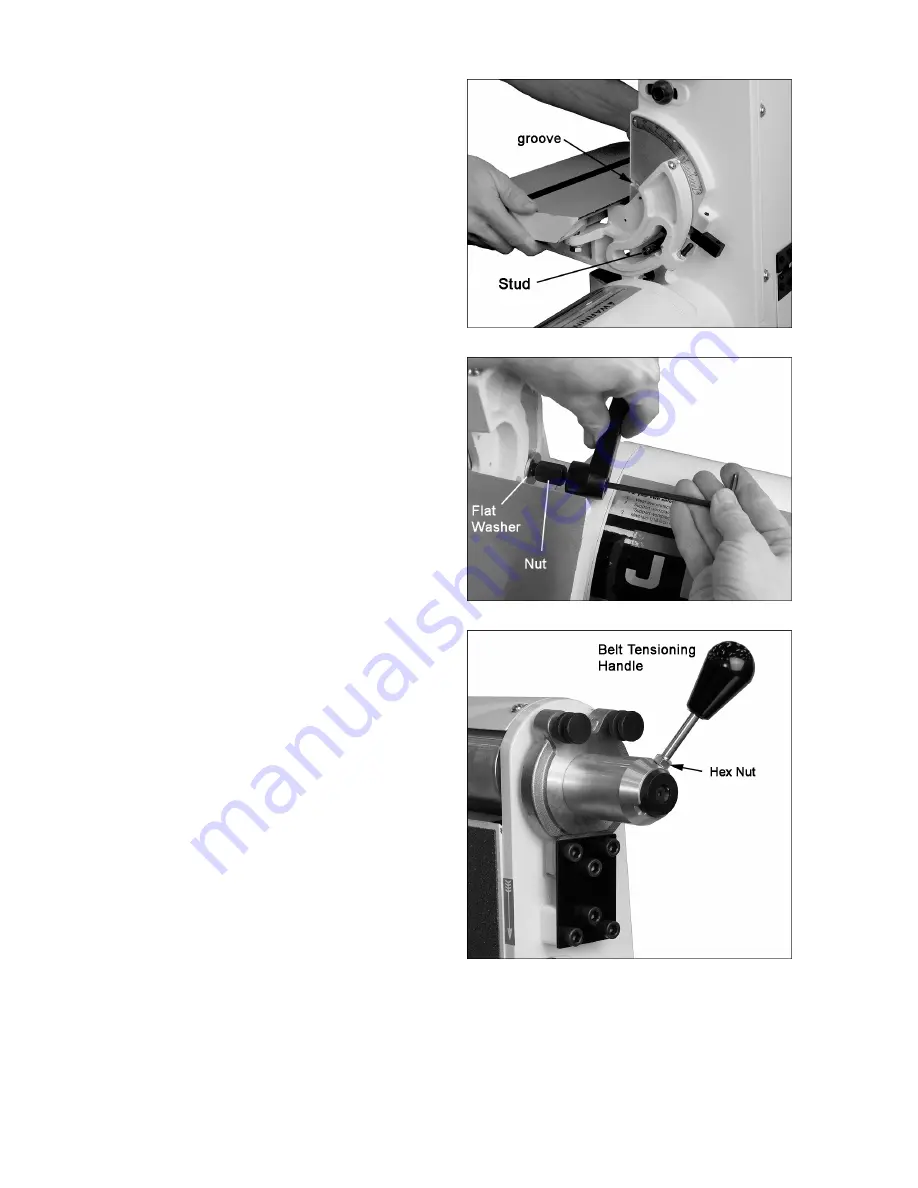

2. Guide the belt table trunnion onto the stud, as

shown in Figure 14. The raised track on the

trunnion must fit into the groove on the belt

arm.

3. Place the remaining M10 flat washer onto the

stud (Figure 15).

4. Thread the nut of the table lock handle (Figure

15) onto the stud. To do this quickly, pull out

on the handle, while tightening the nut with a

4mm hex wrench. When the nut is fully

tightened onto the stud, release the handle,

making sure it seats itself back onto the nut.

Note:

The table lock handle can be

repositioned at any time for convenience by

pulling out on the handle, rotating it to new

position, then releasing it. Make sure it re-

seats itself on the nut.

5. Screw the belt tensioning handle (Figure 16)

into the threaded hole in the belt tracking

assembly, and tighten the hex nut against the

shaft with a 13mm wrench.

6. See “Adjustments” section for further

instruction on adjusting the belt table.

Installing Abrasives

Abrasive Disc

Note: You may wish to check the angle setting of

the table before installing the abrasive disc. See

“Disc Table Adjustment”.

To install the abrasive disc:

1. Disconnect machine from power source.

2. Make sure the aluminum disc is clean and dry.

3. Peel the backing from the abrasive and

carefully insert it between disc and table; align

and press into place.

4. Rotate disc a half turn and press other half of

abrasive into place. Make sure to remove any

entrapped air by pressing all parts of the

abrasive against the disc.

Figure 13

Figure 14

Figure 15

Figure 16