8

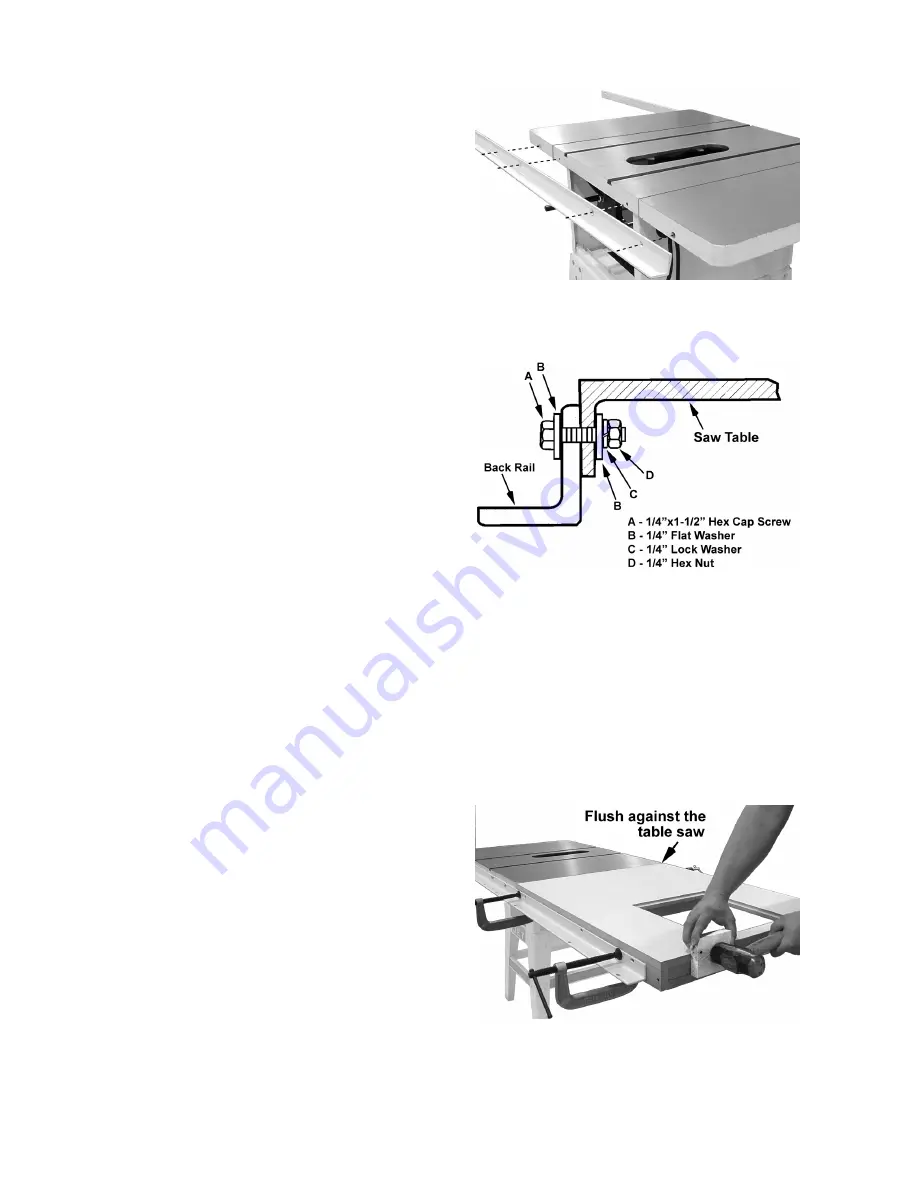

Back Rail Installation

1. Locate the

back rail

which is 1-1/2" x 1-1/2"

with holes running along one side only. The

height of the back rail when attached to the

saw is not critical.

2. Align the holes in the

back rail

to the holes in

the table top, as shown in Figure 4.

3. Secure the

back rail

to the holes in the saw

table with four 1/4-20x 1-1/2 hex cap screws,

eight 1/4 flat washers, four 1/4 lock washers,

and four 1/4 hex nuts as shown in Figure 5.

Tighten screws securely with two 10mm

wrenches.

Note:

If you are installing an optional wood

extension table on your saw, it should be installed

first

before

mounting the guide tube. This will

prevent having to mount and align the guide tube

twice.

If you are not mounting an optional wood table,

skip the following section and proceed to

Guide

Tube

section.

Wooden Extension Table

The

wooden extension table

is an optional

accessory.

Tools required

Electric drill

Cross point screwdriver

10mm open end wrenches

Four clamps

Straight edge

Hammer (or rubber mallet)

Installation

The optional wood extension table (including the

optional router table) sits flush against the saw

table and along the inside of the rails. The Warning

label on the router table should face outward. The

extension table is not bolted to the saw table; it is

bolted only to the rails.

The extension table and saw table must be aligned

properly so the XACTA Fence II will slide smoothly

from one to the other.

1. Place the extension table between the rails

and up against the saw table, leaving the

extension table raised just slightly above the

saw table.

Clamp the extension table to the front and

back rails as shown in Figure 6. Clamping

pressure should be enough to secure the table

yet allow minor adjustments.

Figure 4

Figure 5

Figure 6

2. Use a hammer and block of wood (or a rubber

mallet) to tap the extension table up flush

against the cast iron saw table (Figure 6).