5

Operation and Setup

The 12” Master Dovetail Jig comes with a 1/2"

template. It should be used with a 1/2" dovetail

router bit (1/4" shank, 14°), and a 7/16” guide

bushing.

Always set up and practice on a test piece.

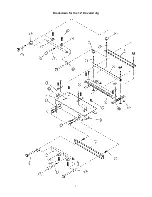

1. Lay out the workpieces and mark according

to the finished position, see Figure 2.

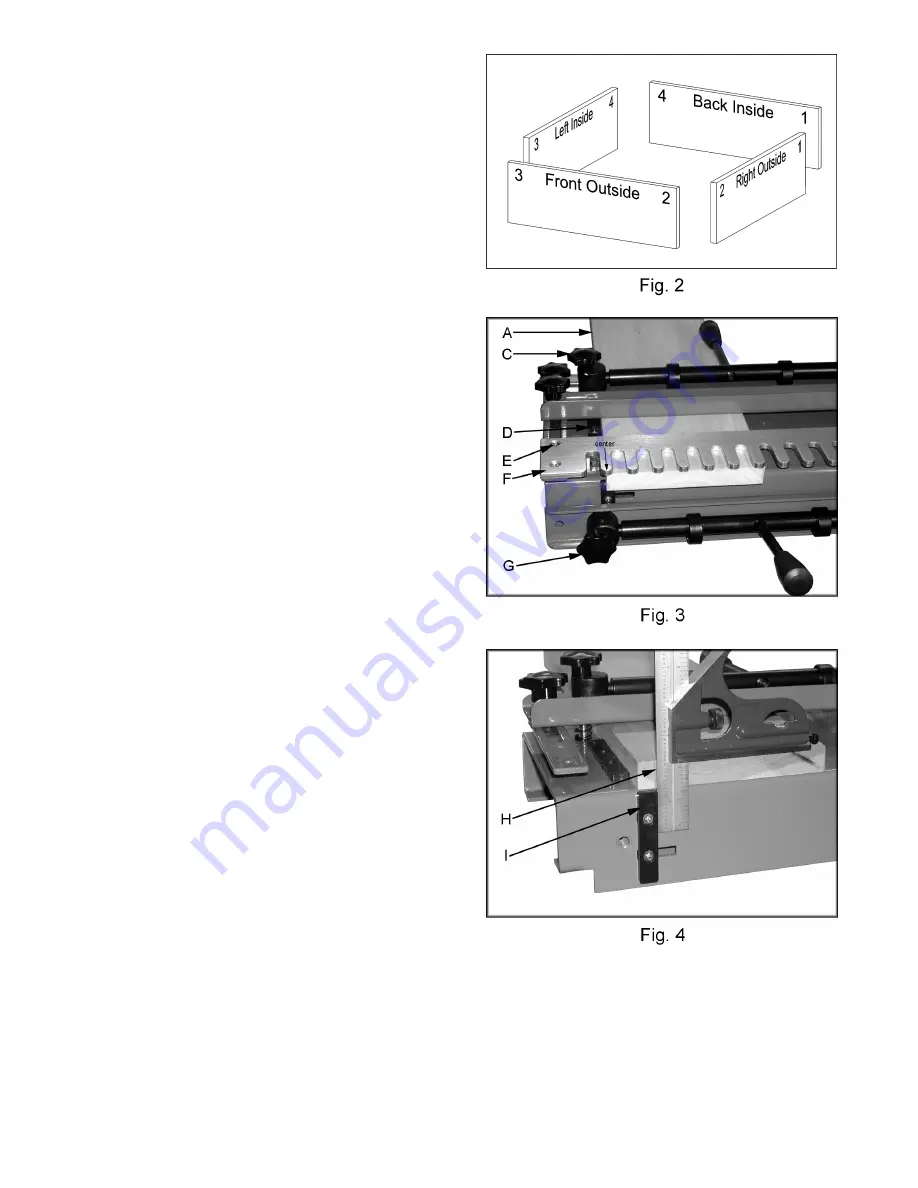

2. Slide the workpiece marked “front,” or “back”

(A, Fig. 3) under the top clamping assembly

when handle is in the up position. The side

marked inside should face up.

3. Adjust the clamping pressure knobs (C, Fig.

3) so that the bar is just over the workpiece.

The workpiece should still move freely. Hold

the workpiece in place by pushing the

handle away from you. You should not need

to use excessive force to clamp the

workpiece.

4. Set the horizontal stop (D, Fig. 3) so that the

edge of workpiece lines up in the center of

one of the template fingers, see Figure 3.

5. Take off the template (F, Fig. 3) by removing

the four screws (E, Fig. 3) that hold the

template in position.

6. Remove the front clamping assembly by

unscrewing two knobs (G, Fig. 3).

7. Mark workpiece 1/2" from the edge (H, Fig.

4) (template finger width). Adjust the vertical

stop against the (I, Fig. 4) square.

8. Reinstall the template and front clamping

assembly.

9. Slide the workpiece marked “side” under the

front clamping assembly when handle is in

the release position. The side marked

“inside” should face out. Match up the

numbers you marked.

10. Adjust the clamping pressure knobs so that

the bar is just over the workpiece. The

workpiece should still move freely. Clamp

the workpiece in place by pushing the

handle down. You should not need to use

excessive force to clamp the workpiece.