18

9.6.6

Face frames and raised panel

doors

It is very important to have the proper abrasive

contact when doing this type of sanding. If the

machine is set to take an excessive depth of cut, the

result can be a gouge or dip as the drum goes from

sanding the rails at full width to sanding just a few

inches of width on the stiles. To prevent this make

sure, when using abrasives finer than 80 grit, that

the drum is in contact with the wood but can still be

spun by hand. If there is room, angling the stock on

the conveyor belt can also help.

Slowing the conveyor feed when coming to a rail in

the stock can help prevent a dip or gouge. This

allows the abrasive to work the wider width with less

effort, and to achieve better consistency of the

finished surface.

9.6.7

Stock feeding angle

Some pieces, because of their dimensions, will

need to be fed into the machine at a 90° angle

(perpendicular to drum). However, even a slight

offset angle of stock will provide for more effective

stock removal. The optimum feeding angle for stock

removal is about 60°.

Angling the workpiece for stock removal provides

other advantages, such as less loading of certain

areas of the drum due to glue lines or mineral

streaks in the stock, more even wear of abrasive

strips, potentially faster feed rates, and lighter loads

on the motor. Note that to get the best final finish,

however, the stock should be fed through the

machine so it will be sanded in line with the grain of

the wood on the final one or two passes.

10.0

User-maintenance

Before doing maintenance on

the machine, disconnect it from the electrical

supply (pull out the plug), unless indicated

otherwise. Failure to comply may cause serious

injury.

10.1

Cleaning and lubrication

For best results, make cleaning the sander a regular

shop procedure. Allowing excess build-up of dust

and debris can adversely affect performance

through loading of the abrasives, slippage on the

conveyor table, and/or the accumulation of material

inside the drums which can throw off the center of

balance.

NOTE: Bearings are pre-sealed and require no

lubrication.

Brush the conveyor belt after cleaning

operations. If not cleaned, the conveyor belt

could allow stock to slip during sanding

operations.

Lubricate conveyor bushings as needed, and

check for wear.

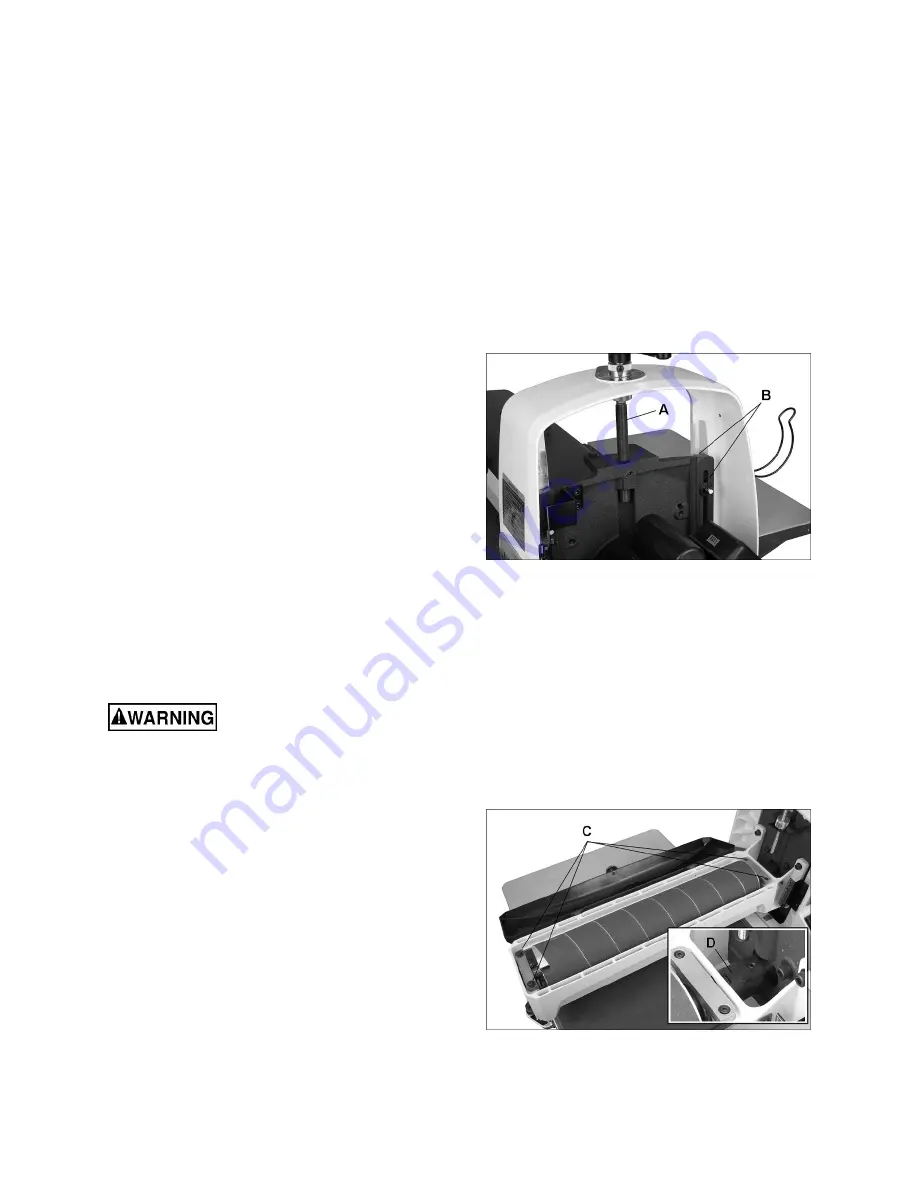

Lubricate elevating leadscrew (A, Figure 10-1)

as needed.

Clean sawdust from abrasive strip and brush

dust from conveyor belt.

Keep slide areas clean (B, Figure 10-1).

Blow dust from motors and switches.

Blow dust from inside of sanding drum, which

may cause vibration or offset the center of

balance. (Leave your dust collector on when

cleaning dust from the drums.)

Check all set screws for tightness on parts such

as bearings, conveyor table, and couplings.

Figure 10-1

10.2

Drum maintenance

The drum should not require removal from the

machine under normal circumstances. Should

maintenance ever become necessary, the drum has

been designed for easy removal and replacement.

1. Disconnect sander from power source/unplug.

2. Remove four socket head screws (C, Figure 10-

2).

3. Carefully lift out drum with coupling (D)

attached.

Figure 10-2: drum removal