9

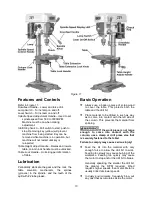

Mounting the Head

1. With

the aid of a second person, carefully lift

the

head

onto the

column top

(Figure 3).

The head assembly is heavy!

To avoid injury and/or damage to equipment, lift

the head onto the column only with additional

assistance!

2. Rotate head assembly until sides of the

belt

cover

(E) are parallel with the sides of the

base

(D, Fig. 1).

3. Tighten

two

set screws

(A, Fig. 3) with a 5mm

wrench until they are snug.

Downfeed Handles

Referring to Figure 3:

Install three

downfeed-handles

(B) into the

downfeed-hub

(C) as shown.

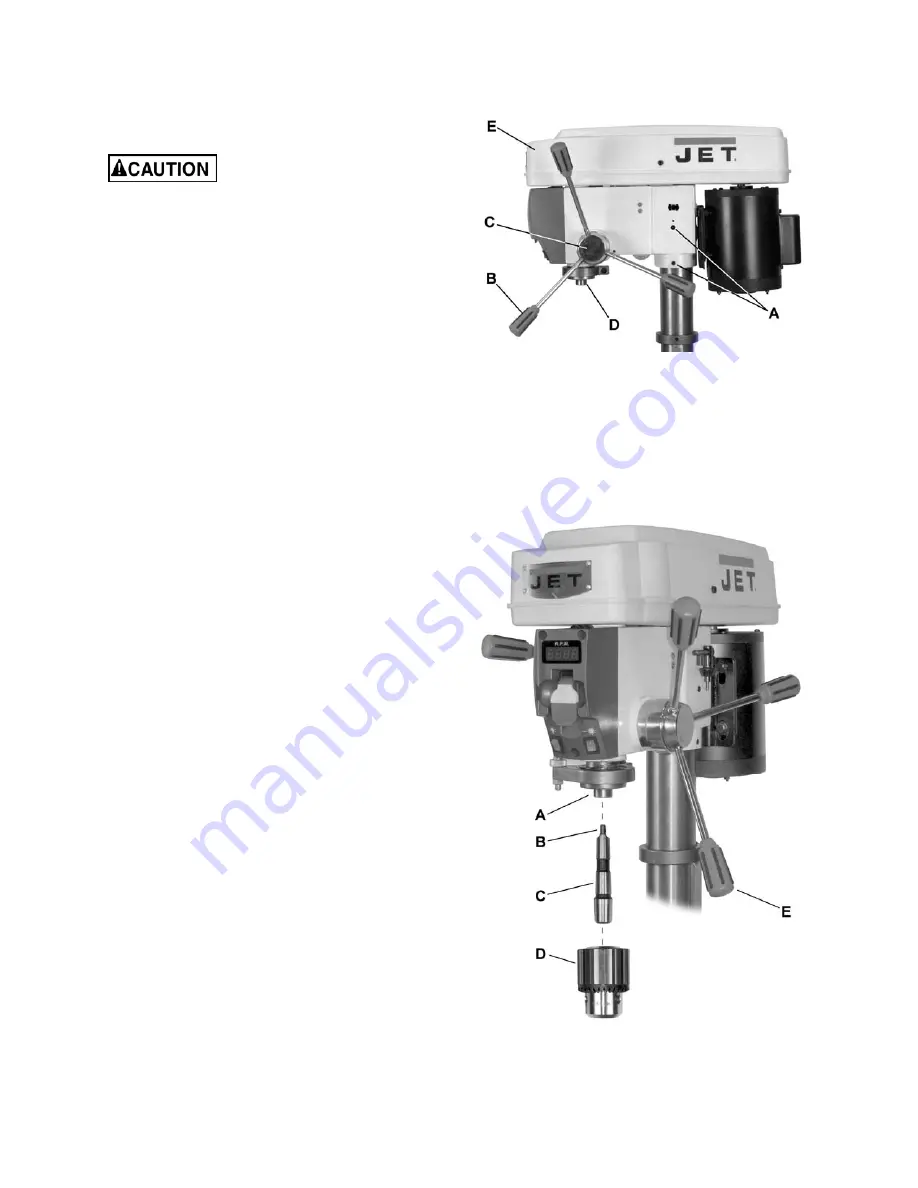

Installing the Chuck and Arbor

1. Adjust the position of the table to approximately

seven inches below the

spindle assembly

(D, Fig. 3) and lock in place.

Referring to Figure 4:

2. Thoroughly clean

spindle

(A),

arbor

(C), and

chuck

(D).

Important:

These three pieces must be free of

any rust protection, or lubricant. If they are not

clean and dry, the arbor and chuck will fail to

seat in the spindle.

3. Place

arbor

(C) into the

chuck

(D).

4. Open chuck all the way to completely retract

the chuck jaws.

5. Place arbor and chuck assembly into the

spindle

(A).

6. Turn the arbor and chuck assembly until the

tang

(B) on the

arbor

(C) engages the slot at

the end of the spindle.

7. Place a scrap board against the bottom of the

chuck, and firmly tap the board two or three

times with a mallet or hammer, to seat the

arbor.

Figure 3

Figure 4

Summary of Contents for Bench JDP-12

Page 18: ...18 Assembly Drawing ...