5

Warnings

1. Read and understand the entire owners' manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This saw is designed and intended for use by properly trained and experienced personnel only. If you

are not familiar with the proper and safe operation of a compound miter saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this saw for other than its intended use. If used for other purposes, Walter Meier

(Manufacturing) Inc., disclaims any real or implied warranty and holds itself harmless from any injury

that may result from that use.

6. Always wear approved safety glasses/face shields while using this miter saw. Everyday eyeglasses

only have impact resistant lenses; they are not safety glasses.

7. Before operating this saw, remove tie, rings, watches and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do

not

wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

•

Lead from lead based paint.

•

Crystalline silica from bricks, cement and other masonry products.

•

Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the

OFF

position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure this machine is firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Don't use in dangerous environment. Don't use power tools in damp or wet locations, or expose them

to rain. Keep work area well lighted.

21. Keep visitors a safe distance from the work area.

Keep children away.

22. Make your workshop child proof with padlocks, master switches or by removing starter keys.

Summary of Contents for Bench JMS-12SCMS

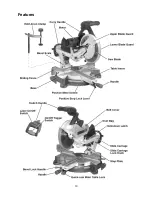

Page 10: ...10 Features...

Page 36: ...36 Assembly Drawing...

Page 37: ...37 Assembly Drawing...

Page 38: ...38 Assembly Drawing...

Page 39: ...39 Wiring Diagram...