12

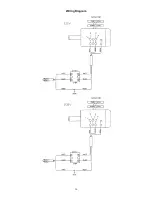

Electrical Connections

WARNING

All electrical connections must be done by a

qualified electrician. All adjustments or

repairs must be done with the dust collector

disconnected from the power source,

unplugged. Failure to comply may result in

serious injury!

The DC-1100C dust collector is rated at

115/230V, Prewired 115V. Use a plug and

outlet rated at least 20 amps. The circuit for the

machine should also be protected by at least a

20 amp circuit breaker or fuse. Keep in mind

that a curcuit being used by other machines,

tools, lights, heaters, etc. at the same time will

add to the electrical load. A dedicated curcuit to

the dust collector will give you the best results

since dust collectors are generally used at the

same time other tools are running.

Before hooking up to the power source, make

sure that the switch is in the off position.

Turning the Machine On & Off

Before hooking up to the power source, make

sure that the switch is in the off position.

The dust collector can be turned on by pressing

the start button mounted next to the motor.

Press the stop button to turn off the dust

collector.

Maintenance

WARNING

Never perform maintenace on this machine

before turning switch off and removing plug

from power source, unplug.

Failure to comply may cause serious injury!

Cleaning the Filter

Clean both the filter and collector bag frequently

to keep the collector's performance at its

optimum.

To clean the filter turn the handle a couple

rotations so the dust falls into the collector bag.

Removing the Collector Bag

CAUTION

Wearing a particle mask/respirator for

protection against fine dust particles during

cleaning is highly recommended.

1. Disconnect the machine from the power

source, unplug.

2. Remove the collector bag by pushing the

ring of the collector bag upwards at an angle

and pulling the bag and snap ring out.

3. Empty the contents into an appropriate

container.

4. See Page 8 for details on replacing the

collector bags.

Motor

Make frequent inspections of the motor fan and

blow out (with low pressure air hose) or vacuum

any accumulation of foreign material in order to

maintain normal motor ventilation.

Connecting the Dust collector to a

Machine

Use the proper type hose to connect the dust

collector to the machine being operated. Dryer

vent hose is not acceptable for this purpose.

Contact your nearest JET distributor for the full

line of JET Dust Collector Hoses and

Accessories. Customize your installation and

obtain maximum performance with JET's dust

hoods, hoses, clamps, fittings, and blast gates.

You can also purchase the JET “Dust Collection

Basics Video” stock # JW1050V through your

JET Distributor

Grounding the Dust Collection System

The dust collection system includes the dust

collector and the hose, or duct work you use to

connect the tools. The dust collector is grounded

though the ground wire in the cord. The hose or

duct work you use to connect the tool to the dust

collector must also be grounded. To assist in

grounding your system you can purchase the JET

“Dust Collector Grounding Kit” stock # JW1053,

and also the JET “Dust Collection Basics Video”

stock # JW1050V through JET Distributors.