5

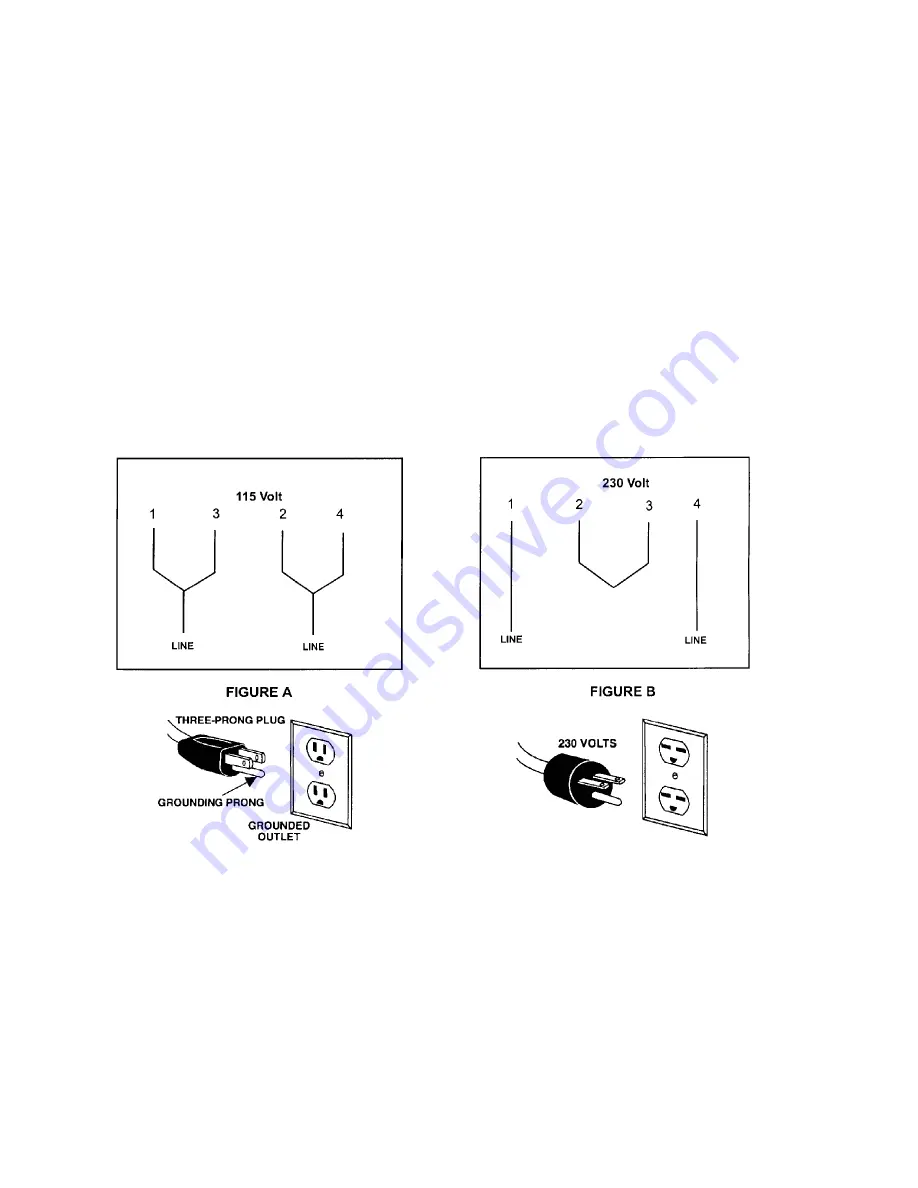

230 Volt Operation

If 230V, single phase operation is desired, the following instructions must be followed:

1. Disconnect the machine from the power source.

2. This dust collector is supplied with four motor leads that are connected for 115V operation, as shown

in Figure A. Reconnect these four motor leads for 230V operation, as shown in Figure B.

3. The 115V attachment plug supplied with the dust collector must be replaced with a UL/CSA listed

plug suitable for 230V operation. Contact your local Authorized JET Service Center or qualified

electrician for proper procedures to install the plug. The dust collector must comply with all local and

national codes after the 230V plug is installed.

4. The dust collector with a 230V plug should only be connected to an outlet having the same

configuration. No adapter is available or should be used with the 230V plug.

Important: In all cases (115 or 230 volts), make certain the receptacle in question is properly

grounded. If you are not sure, have a registered electrician check the receptacle.