11

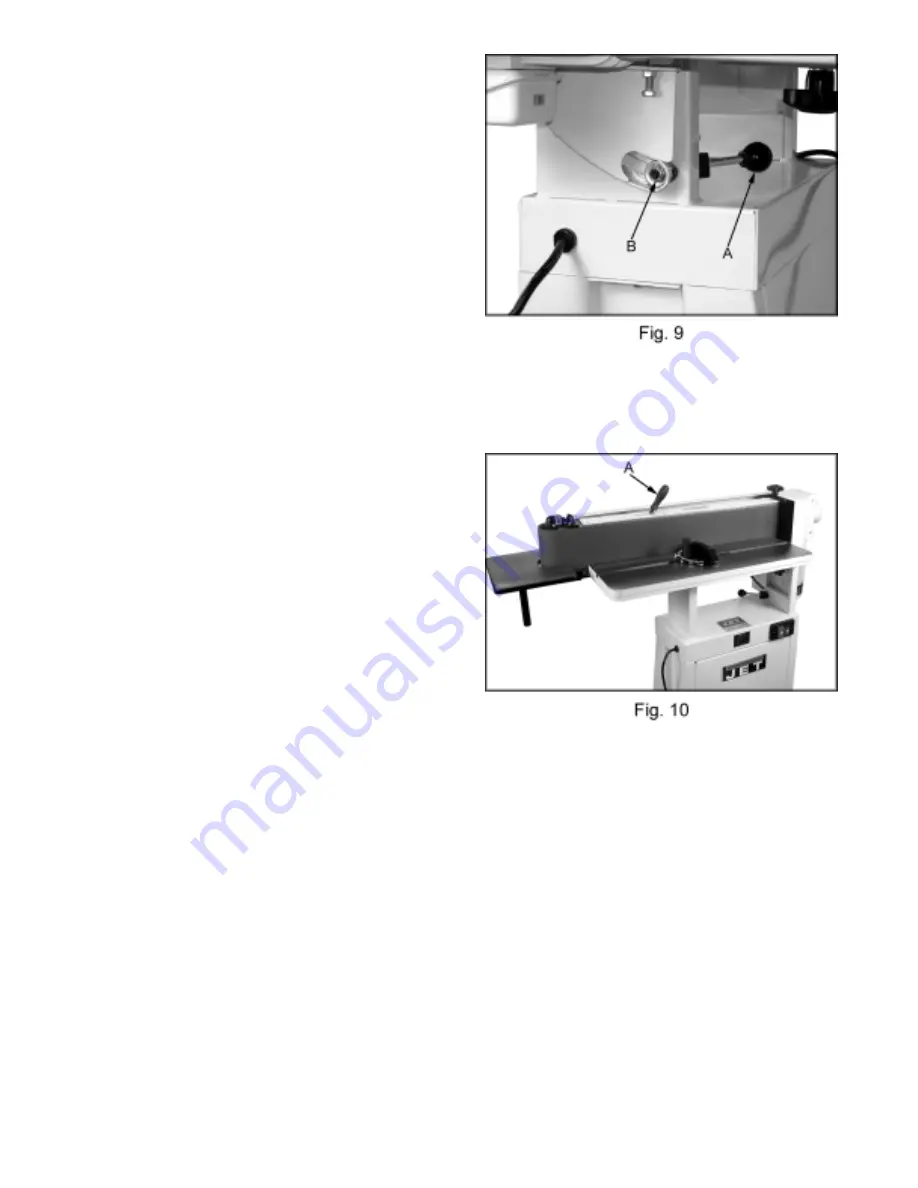

Platen Lock Tension Adjustment

1.

Disconnect the machine from the power

source.

2.

Loosen lock handle by pulling forward (A,

Fig. 9) and move motor and sanding table

toward the horizontal position. Do not lock.

3.

Tension eccentric block by tightening the

nyloc nut (B, Fig. 9) with a 14mm wrench.

Turn the nut in ¼ turn increments and test

locking handle for proper tension. Locking

handle

is

properly

tensioned

when

it

requires

positive

force

to

move

the

eccentric block (attached to the locking

handle) from one side to the other.

The

platen and motor assembly must stay in a

locked position without sliding once the

handle has been moved to the locked

position. Re-adjust as necessary.

Changing the Sanding Belt

1.

Disconnect the machine from the power

source.

2.

Lock sanding platen in the vertical position.

3.

Release tension on the belt by pushing

handle (A, Fig. 10) to the left (as the

operator faces the machine).

4.

Remove belt guards.

5.

Carefully

remove

old

belt.

Observe

direction arrow on inside of sanding belt.

Make sure that direction arrow on belt

matches direction indicator on the belt

cover. Install new belt over both rollers and

line up edge of belt with edge of rollers.

6.

Tension belt by pushing handle to the right.

7.

Reinstall the belt guards

Note: Belts stretch with wear. You may have to

adjust tracking with a new belt.

Belt Tracking Adjustment

1.

Disconnect the machine from the power

source.

2.

Push the belt by hand in the direction

indicated on the belt cover.

Observe the

belt position on the rollers.

Edge of belt

should remain even with the edge of the

rollers.

Summary of Contents for EHVS-80CS

Page 14: ...14 Table and Motor Assembly ...

Page 19: ...19 ...