11

Four-Way Tool Post

(K).

The tool post is a

turret design, mounted to the compound rest. It

holds up to four tools simultaneously, and

includes an indexing function.

(Always use a

minimum of two clamping screws when installing

a cutting tool.)

Tailstock

The tailstock (L) slides on a v-way and can be

locked at any location by a clamping lever. The

tailstock has a heavy duty quill with a No. 4 Morse

Taper or No. 5 Morse Taper (18” and 22” models)

and etched graduation scale. The tailstock can be

offset for taper cutting.

Leadscrew and feed rod

The leadscrew (M) and feed rod (N) are mounted

on the front of the machine bed. They are

connected to the gearbox at the left and are

supported by bearings on both ends. Both are

equipped with shear pins.

Spindle direction control axle

(O)

Spindle rotation can be reversed by simply moving

the control lever (P) mounted at the right of the

carriage. (Allow spindle to come to a stop before

reversing.)

Travel setting rod

(Q)

The stops can be moved and tightened into

position at any point along the rod, to limit travel of

the carriage.

Thread chaser

(R)

Simplifies the process of setting leadscrew/carriage

positions in relation to the workpiece, by indicating

the point on the leadscrew where the half nut can

be reengaged to continue threading.

Steady rest

(S)

The steady rest serves as a support for shafts on

the free tailstock end. The steady rest is mounted

on the bedway and secured from below with a bolt,

nut and locking plate.

Follow rest

(T)

The traveling follow rest is mounted to the saddle,

and thus follows the movement of the turning tool.

Only two fingers are required as the place of the

third is taken by the turning tool. The follow rest is

used for turning operations on long, slender work

pieces. It prevents the work piece from flexing

under the pressure of the cutting tool.

Work lamp

(U)

Adjustable halogen lamp with independent on/off

switch.

Coolant nozzle

(V)

Fully adjustable gooseneck; flow is regulated

through a valve lever at its base.

Foot brake

(W)

Activates a braking strap at the motor for

emergency stopping of all lathe functions.

Chuck guard

(X)

Hinged, with upper and front windows.

Micro stop

(Y)

Used for manual carriage operation.

Summary of Contents for GH-1440ZX

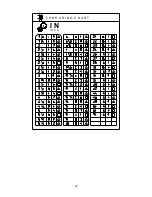

Page 26: ...26 T H R E A D I N G C H A R T I N I N C H ...

Page 27: ...27 m m M E T R I C T H R E A D I N G C H A R T M P M O D U L E P I T C H ...

Page 31: ...3 1 1 Stand Assembly Exploded View ...

Page 34: ...6 2 1 Brake Assembly Exploded View ...

Page 36: ...8 3 1 Bed Assembly Exploded View ...

Page 39: ...11 4 1 Headstock Assembly I Exploded View ...

Page 43: ...15 5 1 Headstock Assembly II Exploded View ...

Page 46: ...18 6 1 Headstock Assembly III Exploded View ...

Page 48: ...20 7 1 Headstock Assembly IV Exploded View ...

Page 50: ...22 8 1 Change Gear Box Assembly I Exploded View ...

Page 52: ...24 9 1 Change Gear Box Assembly II Exploded View ...

Page 54: ...26 10 1 Quick Change Gear Box I Exploded View ...

Page 57: ...29 11 1 Quick Change Gear Box II Exploded View ...

Page 59: ...31 12 1 Quick Change Gear Box III Exploded View ...

Page 61: ...33 13 1 Apron Assembly I Exploded View ...

Page 64: ...36 14 1 Apron Assembly II Exploded View ...

Page 67: ...39 15 1 Apron Assembly III Exploded View ...

Page 69: ...41 16 1 Carriage Assembly Exploded View ...

Page 73: ...45 18 1 Carriage Stop Assembly Exploded View ...

Page 75: ...47 19 1 Quick Change Tool Post Exploded View ...

Page 77: ...49 20 1 Tailstock Assembly I Exploded View ...

Page 79: ...51 21 1 Tailstock Assembly II Exploded View ...

Page 81: ...53 22 1 Steady Rest Assembly Exploded View ...

Page 83: ...55 23 1 Follow Rest Assembly Exploded View ...

Page 85: ...57 24 1 Coolant Work Light Assembly Exploded View ...

Page 89: ...61 26 2 Electrical Cabinet Breakdown 6 7 8 12 11 10 17 22 21 23 13 9 9a 20 18 3a 1 2 4 19 3 ...

Page 90: ...62 27 0 Wiring Diagram ...

Page 94: ...66 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...