24

15.0

Lubrication schedule and general maintenance

Regularly scheduled maintenance is crucial to ensure a long service life for your machine. The schedule below shows

general cleaning, lubrication points and coolant replacement information for the ZX Series Lathes.

Push stop button

and power off before lubricating.

Follow local regulations for disposal of used coolant/lubricants. Minimize direct

skin contact with lubricants and coolants, and wear eye protection when pouring coolant in case of splash.

Mobile DTE® Oil Heavy Medium is recommended for the SAE-20W machine oil.

If the brand of oil is ever changed, it is recommended that you flush and clean the reservoir first to prevent any

compatibility issues.

Table 1

Section Element

Action

Lubricant

Frequency

8.3

Chuck

Grease jaws and scroll

#2 lithium tube grease

periodically

8.3

Spindle/cam locks/

chuck body

light coat of oil

SAE-20W machine oil

periodically

All exposed metal

surfaces

light coat of oil

SAE-20W machine oil

frequently

9.0

Headstock

Drain and fill

SAE-20W machine oil

- after 30 days,

- every 2 months

9.0

Gearbox

Drain and fill

SAE-20W machine oil

- after first 3 months,

- every 6 months

9.0

Apron and Saddle

Drain and fill

SAE-20W machine oil

- after first 3 months,

- then annually

9.0

Leadscrew; Feed Rod;

Spindle Direction

Control Axle

Fill at ball oilers

SAE-20W machine oil

daily (1 or 2 times per

shift)

Travel Setting Rod

Fill at (1) ball oiler

SAE-20W machine oil

as needed

9.0

Cross slide

Fill at (2) ball oilers

SAE-20W machine oil

daily

9.0

Compound rest

Fill at (2) ball oilers

SAE-20W machine oil

daily

9.0

Tailstock

Fill at (1) ball oiler

SAE-20W machine oil

daily

9.0

Anti-dust felt on v-ways

Clean

kerosene

Inspect weekly

10.0 Coolant

reservoir

(follow coolant

manufacturer’s

directions)

Coolant of choice,

approx. 4 gallons

(follow coolant

manufacturer’s

directions)

14.10 Steady

Rest

Lubricate finger shafts

and contact points

Lead-based grease

before each use

14.11 Follow

Rest

Lubricate finger shafts

and contact points

Lead-based grease

before each use

14.6 V-belts

Inspect and tighten if

needed

periodically

Summary of Contents for GH-1440ZX

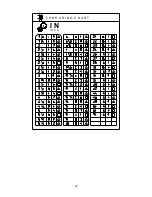

Page 26: ...26 T H R E A D I N G C H A R T I N I N C H ...

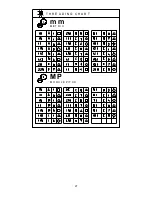

Page 27: ...27 m m M E T R I C T H R E A D I N G C H A R T M P M O D U L E P I T C H ...

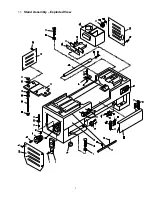

Page 31: ...3 1 1 Stand Assembly Exploded View ...

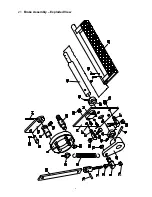

Page 34: ...6 2 1 Brake Assembly Exploded View ...

Page 36: ...8 3 1 Bed Assembly Exploded View ...

Page 39: ...11 4 1 Headstock Assembly I Exploded View ...

Page 43: ...15 5 1 Headstock Assembly II Exploded View ...

Page 46: ...18 6 1 Headstock Assembly III Exploded View ...

Page 48: ...20 7 1 Headstock Assembly IV Exploded View ...

Page 50: ...22 8 1 Change Gear Box Assembly I Exploded View ...

Page 52: ...24 9 1 Change Gear Box Assembly II Exploded View ...

Page 54: ...26 10 1 Quick Change Gear Box I Exploded View ...

Page 57: ...29 11 1 Quick Change Gear Box II Exploded View ...

Page 59: ...31 12 1 Quick Change Gear Box III Exploded View ...

Page 61: ...33 13 1 Apron Assembly I Exploded View ...

Page 64: ...36 14 1 Apron Assembly II Exploded View ...

Page 67: ...39 15 1 Apron Assembly III Exploded View ...

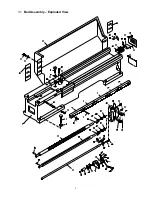

Page 69: ...41 16 1 Carriage Assembly Exploded View ...

Page 73: ...45 18 1 Carriage Stop Assembly Exploded View ...

Page 75: ...47 19 1 Quick Change Tool Post Exploded View ...

Page 77: ...49 20 1 Tailstock Assembly I Exploded View ...

Page 79: ...51 21 1 Tailstock Assembly II Exploded View ...

Page 81: ...53 22 1 Steady Rest Assembly Exploded View ...

Page 83: ...55 23 1 Follow Rest Assembly Exploded View ...

Page 85: ...57 24 1 Coolant Work Light Assembly Exploded View ...

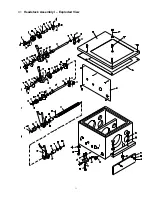

Page 89: ...61 26 2 Electrical Cabinet Breakdown 6 7 8 12 11 10 17 22 21 23 13 9 9a 20 18 3a 1 2 4 19 3 ...

Page 90: ...62 27 0 Wiring Diagram ...

Page 94: ...66 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...