15

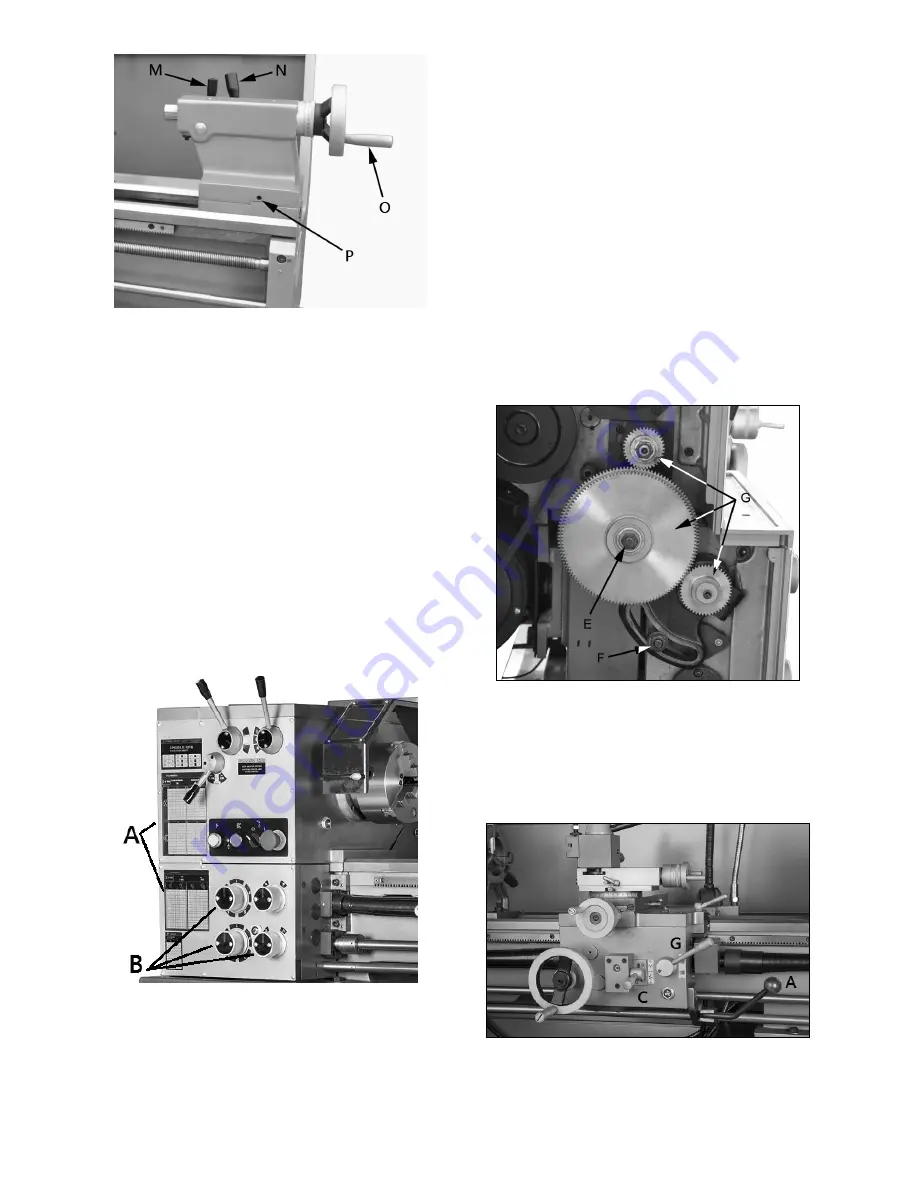

Figure 9-4

10.0

Operation

10.1

Break-in procedure

During manufacturing and testing, this lathe has

been operated in the low RPM range for three

hours.

To allow time for the gears and bearings to break-

in and run smoothly, do not run the lathe above

755 RPM for the first six hours of operation and

use.

10.2

Feed and thread selection

1. Reference the feed and thread table (A, Figure

10-1).

2. Move knobs and handle (B, Figure 10-1) to

appropriate positions.

Figure 10-1

10.3

Change gear replacement

Note

: The 24T, 127T, and 48T gears are installed

in the end gear compartment when delivered from

the factory. This combination will cover most inch

feeds and threads under normal circumstances.

The additional gears found in the toolbox are used

for some metric threads and feeds.

1. Disconnect machine from power source.

2. Open the cover on left end of headstock.

3. Loosen hex nuts (E/F, Figure 10-2). Move

quadrant out of the way.

4. Change gears (G, Figure 10-2) to match feed

and thread chart.

5. Thoroughly clean and install new gears.

6. Move quadrant so the large gear meshes with

the smaller gears, and tighten to secure in

place. Note: Make sure there is backlash of

0.002” – 0.003” between gears. Setting gears

too tight will cause excessive noise and wear.

7. Close cover and connect machine to power

source.

Figure 10-2

10.4

Automatic feed operation and

feed changes

1. Move the forward/reverse selector (A, Figure

10-3) up or down depending on desired

direction.

Figure 10-3

Summary of Contents for GHB-1236

Page 18: ...18 12 0 Thread and feed chart Table 3 ...

Page 20: ...20 13 2 1 Headstock Assembly Exploded View ...

Page 21: ...21 ...

Page 24: ...24 13 3 1 Gearbox Assembly Exploded View ...

Page 25: ...25 ...

Page 28: ...28 13 4 1 Apron Assembly Exploded View ...

Page 31: ...31 13 5 1 Cross Slide Assembly Exploded View ...

Page 33: ...33 13 6 1 Compound Rest Assembly Exploded View ...

Page 36: ...36 13 7 1 Tailstock Assembly Exploded View ...

Page 39: ...39 13 9 1 Feed Rod Assembly Exploded View ...

Page 41: ...41 13 10 2 Motor and Change Gear Enclosure Exploded View ...

Page 43: ...43 13 11 1 Stand Brake Coolant Pump Exploded View ...

Page 44: ...44 ...

Page 46: ...46 13 12 1 Electrical Box Assembly Exploded View ...

Page 48: ...48 13 13 1 Steady Rest and Follow Rest Parts List ...

Page 51: ...51 13 15 1 Accessories Exploded View ...

Page 53: ...53 14 0 Wiring Diagram for GHB 1236 ...

Page 55: ...55 This page intentionally left blank ...

Page 56: ...56 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...