13

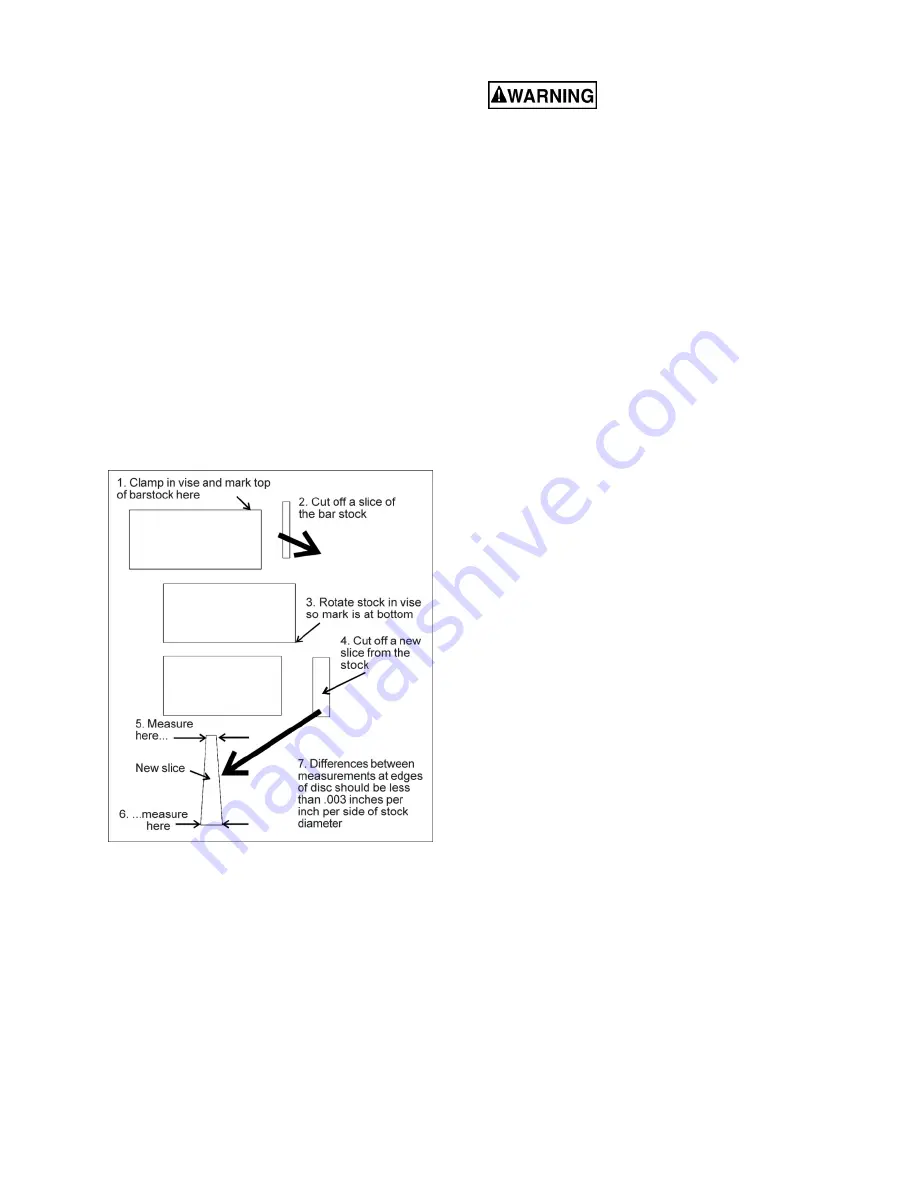

1. With bar stock securely clamped in the vise,

make a cut through the bar stock (see Figure 7-

4).

2. Mark the top of the bar stock.

3. Move the bar stock about 1/4-inch past the

blade to prepare for a second cut.

4. Rotate the bar stock 180 degrees so that your

mark is now at the bottom of the cut.

5. Make a cut through the bar stock.

6. Use a micrometer to measure the thickness

variation of the disk which has been cut from the

bar stock. Measure at top and bottom of disk.

The saw blade can be considered correctly adjusted

when the variation measure is no more than 0.012

inch across the face of the disk.

If you do not have a piece of 2-inch bar stock

available for a test cut, use a larger diameter test

piece rather than a smaller one. The maximum

thickness variation on any test piece should be no

more than 0.003 inch, per side, per inch of stock

diameter.

Figure 7-4: test cut

7.7

Changing blade speeds

Disconnect machine from

power source before changing belt position.

Failure to comply may cause serious injury.

1. Disconnect machine from power source.

2. Open pulley cover.

3. Support motor with one hand while loosening

lock handle (C, Figure 5-3). Lower motor gently.

4. Position belt in grooves according to speed

selection chart on pulley cover. A similar chart

is found in

sect 12.0

.

5. Tension the belt by pushing up motor and

tightening lock handle. Correct tension is

achieved when finger pressure on the belt

midway between the two pulleys causes

approximately 1/2" deflection.

6. Close pulley cover and fasten.

7.8

Bow weight adjustment

Bow weight has been properly set by the

manufacturer and should not require attention. If

future adjustment becomes necessary, due to part

replacement or other contingency, proceed as

follows:

1. Disconnect machine from power source.

2. Raise bow to allow sufficient room for the

following procedure, and use hydraulic valve

knob to keep it in raised position.

3. Place one end of a fish-type scale under the

blade tension handle and lift the bow with the

other end of the scale. The scale should

indicate approximately 18-to-20 lbs. for the

HBS-916. For the HBS-1018, it should indicate

22-to-24 lbs.

4. Adjust tension by loosening one nut on the C-

bolt (L, Figure 7-6) and tightening the other.

Tighten nut and retest the weight.

7.9

Vise adjustments

7.9.1

General procedure

1. Place workpiece between vise jaws with

required amount to be cut-off extending past

blade. (Figure 7-5 shows recommended

positioning of various workpiece shapes within

the vise.)

Summary of Contents for HBS-1018

Page 21: ...21 14 1 1 HBS 916 HBS 1018 Bed and Base Assembly Exploded View ...

Page 22: ...22 14 1 2 HBS 916 Bow Assembly Exploded View ...

Page 23: ...23 14 1 3 HBS 1018 Bow Assembly Exploded View ...

Page 30: ...30 14 2 1 HBS 916 HBS 1018 Gear Speed Reducing Box Exploded View ...

Page 32: ...32 5 0 Electrical Connections 15 1 Electrical Connections HBS 916 only ...

Page 33: ...33 15 2 Electrical Connections HBS 1018 only ...

Page 35: ...35 ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...