12

Coolant Mixture and Quantity

The general purpose coolant is a mixture of water

soluble oil and water. Mix one part of soluble oil

(TRIM SOL) to ten parts of water (one quart oil, ten

quarts of water). The eleven quarts of coolant is the

amount required for the coolant pump to operate

properly.

There are numerous coolants on the market that

are formulated for special applications. Consult your

local distributor for details in the event you have a long

range production task, or are required to cut some of

the more exotic materials.

Adjustments

The efficient operation of the cut-off saw is depen-

dent upon the condition of the saw blade. If the

performance of the saw begins to deteriorate, the first

item that you should check is the blade.

If a new blade does not restore the machine’s

cutting accuracy and quality, refer to the Trouble-

shooting section (or the blade manufacturer's guide)

for conditions to consider and adjustments that can be

made to increase the life of the blade.

To change the blade, refer to

Changing Blades

in

the Maintenance section. To adjust the blade track-

ing, refer to the following procedures.

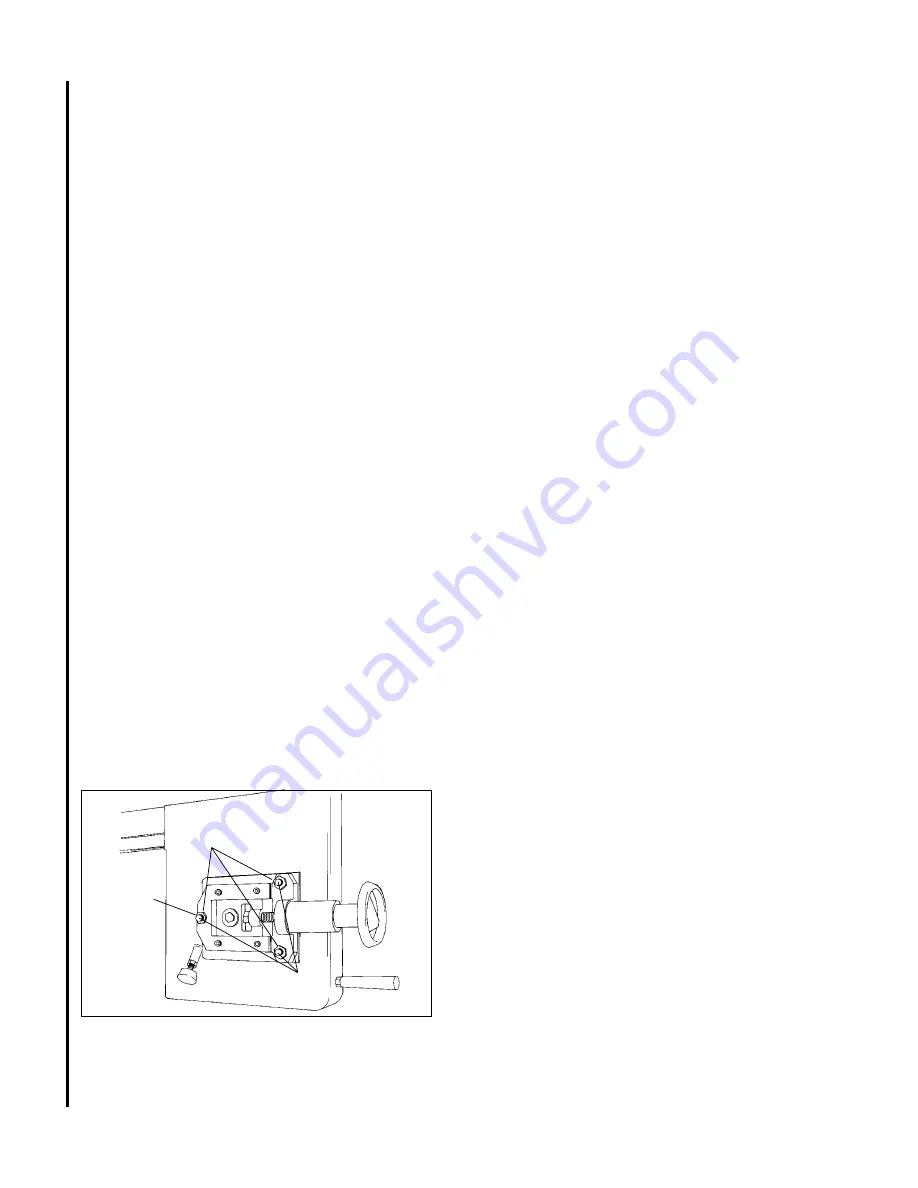

Blade Tracking Adjustment

Blade tracking has been tested at the factory. Adjust-

ment is rarely required when the blade is used

properly or if the blade is correctly welded. (See

figure 12 for location of blade tracking adjustment

screws.)

Factory or Field Procedure

1. Raise the saw head enough to allow the saw

motor to operate.

2. Loosen four knobs securing the blade cover. Lift

the cover and swing it backward.

3. Remove the blade guard mounted on the left blade

guide support.

4. Remove both blade guide bearing brackets.

NOTE:

Maintain proper tension at all times using the

blade tensioning mechanism.

5. Loosen the center locking screws in all three hex

adjustment screws on the blade tensioning

mechanism (see figure 12).

CAUTION:

WHILE PERFORMING THE FOLLOW-

ING, KEEP THE BLADE FROM RUBBING EXCES-

SIVELY ON THE SHOULDER OF THE WHEEL.

EXCESSIVE RUBBING WILL DAMAGE THE WHEEL

AND/OR THE BLADE.

6. Start the saw. Slowly turn the single hex adjust-

ment screw at the rear of the tracking mechanism

to tilt the idler wheel. Do not turn either of the

other two adjustment screws. Turn the adjust-

ment screw until the blade is touching the shoul-

der of the idler wheel.

NOTE:

Turning the screw inward causes the blade to

move toward the shoulder of the wheel. Turning the

screw outward causes the blade to move away from

the shoulder.

7. Turn the single hex adjustment screw so the blade

starts to move away from the shoulder of the

wheel — then immediately turn the single hex

adjustment screw in the other direction so the

blade stops, then moves slowly toward the

shoulder.

WARNING:

KEEP FINGERS CLEAR OF THE

BLADE AND WHEEL TO AVOID INJURY.

8. Turn the single hex adjustment screw to stop the

motion of the blade on the wheel as it gets closer

to the wheel shoulder. Put a 6-inch length of

paper between the blade and the wheel as shown

in figure 13. The paper should not be cut as it

passes between the wheel shoulder and blade.

9. Turn the single hex adjustment screw a small

amount. Repeat the insertion of the paper be-

tween the wheel shoulder and the blade until the

paper is cut in two pieces.

NOTE:

You may have to repeat the check with the

paper several times before the blade and the shoulder

cuts the paper into two pieces. Do not hurry the

adjustment. Patience and accuracy here will pay off

with better, more accurate, quieter cutting and much

longer machine and blade life.

10. When the paper is cut, turn the hex adjustment

screw slightly in the counterclockwise direction.

Figure 12: Blade tracking and tensioning

Blade Tracking

Hex Adjustment

Screws

Center

Locking

Screws

Single

Adjustment

Screw