7

Introduction

This manual includes the operating and maintenance

instructions for the JET 10 X 16-inch Miter Cut-Off

Saws, Models J-7020M and J-7040M. This manual

also includes parts listings and illustrations of

replaceable parts for the miter cut-off saws.

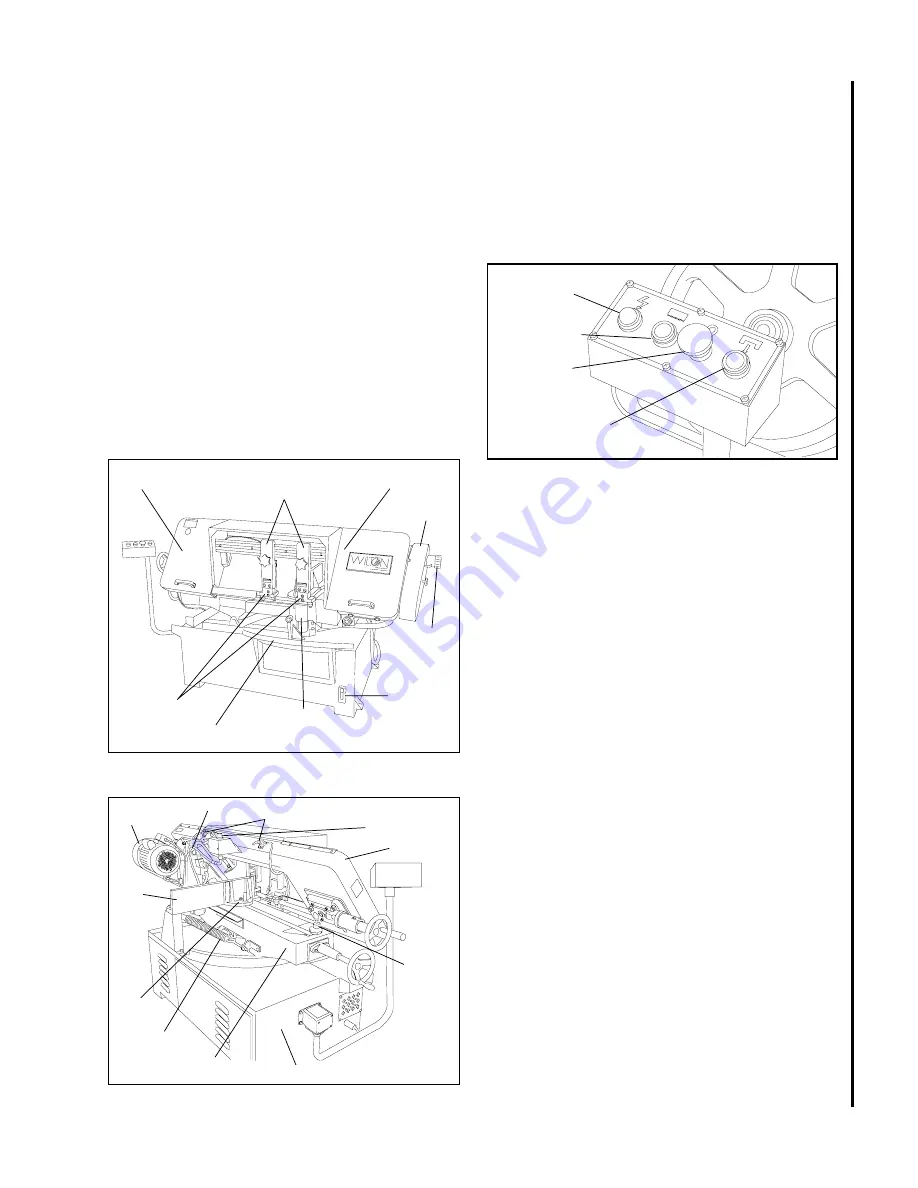

Miter Cut-Off Saw Features

Refer to Figures 1 and 2 for key features of the

Models J-7020M and J-7040M Miter Cut-Off Saw. The

miter cut-off saws are nearly identical to JET's Model

J-7020 and J-7040 cut-off saws except that they are

equipped with a 45 degree swivel head. The swivel

head provides the capability to cut material at angles

from 0 to 45 degrees. The swivel head locks and

unlocks with a quick acting lever.

Saw Head

Blade Guide

Supports

Blade Cover

Belt

Cover

Speed

Control

Coolant

Temperature

Worktable

Pivot Pin

Turn Plate

Blade

Guides

Figure 1: Key Features (Front

View)

Figure 2: Key Features (Rear View)

Drive

Motor

Hydraulic Cylinder

Coolant Valves

Feed Rate

Control

Saw Head

Table

Hard Stop

Base

Work

Table

Counter-

balance spring

Vise

Jaw

(Fixed)

Vise

Jaw

(Moveable)

Operating Instructions

Controls

The operating controls for the saw are provided in

a control panel on the left side of the machine. The

control panel is mounted on a pivoting tube. The

pivoting tube allows the operator to position the

control panel in a convenient location.

1. A power-on light is provided on the left side of the

control panel. The power-on light indicates when

power is connected to the machine.

2. A large, emergency stop button is provided on

the control panel. The emergency stop button

provides a means to rapidly cut off electrical

power.

3. A saw motor pushbutton switch is provided to the

left of the emergency reset button. The sawmotor

pushbutton switch starts the saw motor and the

E-stop button stops the saw motor.

4. A green pushbutton switch is provided to the right

of the emergency stop pushbutton. The

pushbutton opens an electro-magnetic valve in

the hydraulic cylinder circuit. Opening the valves

allows the saw head to move downward and put

the saw blade in contact with the workpiece.

5. A red release button on the electro-magnetic

valve provides a means to lower the saw head

when power to the machine has been discon-

nected (see figure 6).

6. The rate at which the saw head moves downward

is controlled by a hydraulic feed rate control

located on the top, rear of the saw head (see

figure 5).

7. A coolant pump switch is provided on the electri-

cal equipment box on the back of the machine.

8. The quick acting swivel-head lock (refer to Figure

7) is used to release and lock the swivel-head

when making angular material cuts.

Figure 3: Control panel

Emergency

Reset

Button

Saw Head

Pushbutton

Power-on

Light

Motor

Pushbutton