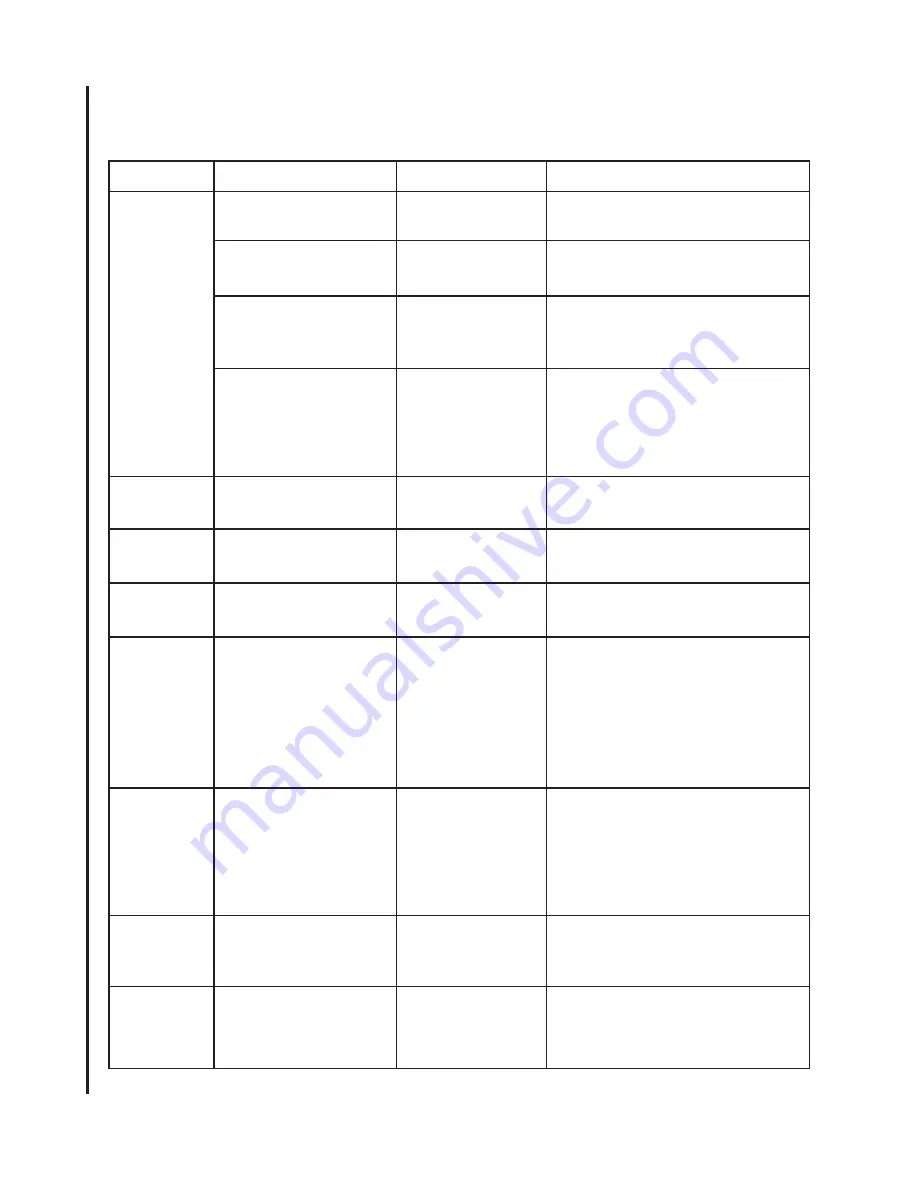

20

Periodic Maintenance

Maintenance

Replace blade when teeth are

broken

Replace blade when bent — or worn

— Use a wider blade for more

accurate straight cuts

Interval

Whenever

operating saw

Whenever

operating saw

When changing

blade

Action

Listen for sound of

missing teeth

Observe cutting

action for cleanness

and accuracy

Listen for a poor weld

— a “click” as it

passes through the

guide blocks

Watch for signs of

slippage on the drive

wheels (blade occa-

sionally slows or

comes to a stop while

sawing)

Check bearing area

for leakage of lubri-

cant

Check bearing area

for leakage of lubri-

cant

Check for cleanliness

Check for smooth

surfaces and adher-

ence to drive wheel

surface

Check for glazing

Check sight glass for

level — should be to

halfway point on sight

glass

Check for wear,

damage or lubricant

leakage

Check for excessive

wear

Item

Saw blade

Whenever

sawing

Use a different blade or dress the

weld with a grinder.

Be sure you are using the correct

blade tension — Check drive wheel

rubber strips for cleanliness and

adherence to drive wheel — replace if

necessary

Lower drive

wheel

Upper drive

wheel

Drive wheel

rubber protec-

tors

Drive belts

Reduction

gearbox

Blade support

bearings

Carbide blade

guides

Monthly

Monthly

Daily and when

changing blade

Monthly or when

blade slippage

occurs

Monthly, or when

slippage occurs

(squealing belt)

Daily

Annually

Monthly and when

changing blade

When changing

blade

Replace bearing if leakage occurs

Replace bearing if leakage occurs

Wipe or brush clean

Clean when necessary — replace if

damaged or excessively worn

Replace a glazed belt — DO NOT USE

BELT DRESSING

Fill up to half-way point on sight glass

with Shell Spirax HD 90

Drain and refill with Shell Spirax

HD 90

Replace when necessary

Replace if excessively worn