9

Operation

Before using the machine:

Check that safety devices (e.g., blade guards)

are in position and work perfectly and that

personal safety requirements are complied

with.

Check the sharpness of the blade and verify

coolant flow.

Operation

1.

Make sure the work piece is securely clamped

in the vise.

2.

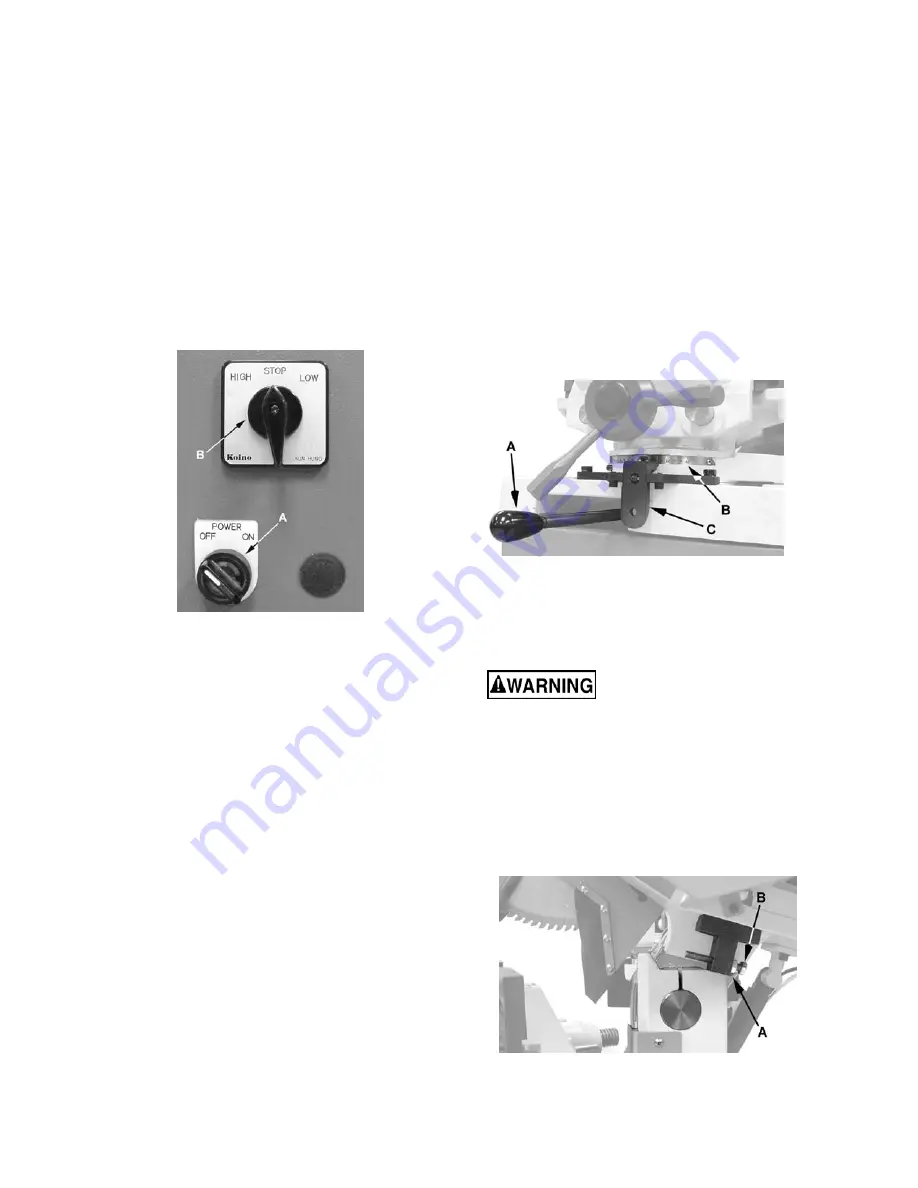

Turn the power on (A, Fig. 8).

3.

Select the cutting speed (B, Fig. 8).

Figure 8

4.

Grip the trigger handle (Figure 5) on the

control lever.

5.

Start the blade by pressing the micro-switch on

the handgrip.

The down stroke speed of the head is controlled

manually by the operator. The coolant pump is

activated during the time that the head is below the

upper limit position.

When the cut is complete:

6.

Raise

the

head.

7.

Remove the work piece from the vise using the

vise hand wheels.

11.1

Stock Stop

Install the shaft of the stock stop into the threaded

hole in the right side of the table. See

sect. 14.2.2

exploded view for reference.

The stop can be used for quickly making multiple

cuts of the same length

11.2

Miter Adjustment

To adjust the miter position follow the steps below

while referring to Figure 10:

1.

Move the miter position lock (A) to the right to

release.

2.

Adjust the head to the desired angle ranging

from –45º to +45º by pushing on the back of

the motor to the right or left. The miter position

is shown on the scale (B).

3.

A detent mechanism locks the head in the -45º,

90º and +45º positions to prevent the head from

rotating. For a miter position other than -45º, 90º

and +45º, press the lever (C) to release while

rotating the head.

4.

When the desired cutting angle is set, move

miter position lock

(A) to the left to secure.

Figure 10

11.3

Depth Stop

The

depth stop

adjustment

limits the lower travel of the

saw blade during a cutting operation.

Remove power when making

this adjustment. Failure to

comply may result in serious injury!

To adjust the depth of cut (refer to Figure 12):

1.

Using two 13mm wrenches, loosen the lock

nut (A).

2.

With the saw in the fully lowered position, turn

the screw (B) until the saw blade bottoms out

at the desired level.

3.

Tighten the lock nut.

Figure 12