8

JAT-500 HVLP Spray Gun

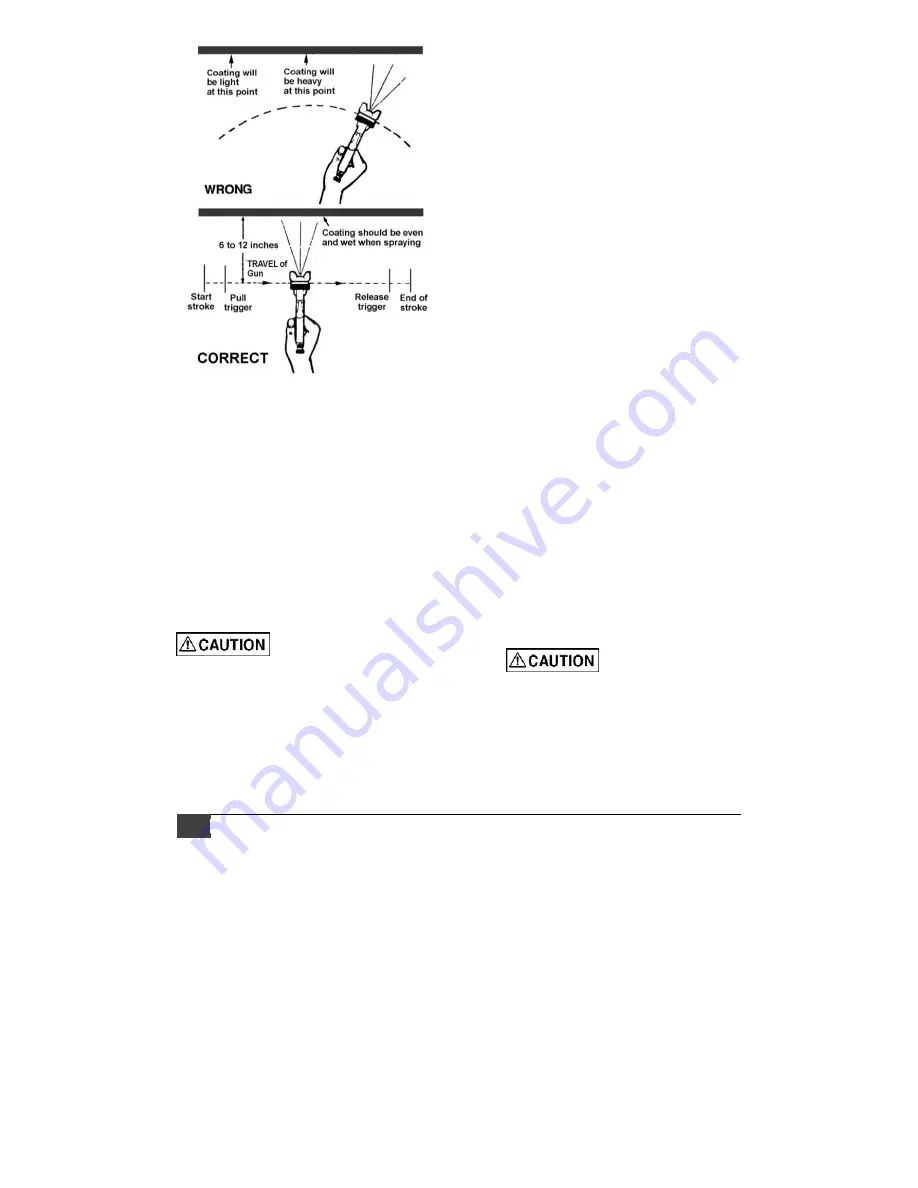

Figure 2

Maintenance

Note: All parts on a spray gun should be screwed

in hand tight at first; this will avoid the possibility

of cross threading the parts. If parts cannot be

turned by hand easily, make sure you have the

correct parts, unscrew, realign and try again.

Never use undue force in mating parts.

All nozzles and needles are precision made – they

should be handled carefully. When changing to a

different nozzle size, make sure that complete

nozzle set is exchanged (air cap/nozzle/needle).

Adjust fluid control knob so that when gun is

triggered, air-flow occurs before fluid-flow.

Do not probe any holes in

nozzle with metal instruments, as damage to

spray gun can affect proper operation.

Cleaning

1. After use, remove cup and drain residual

material. Rinse cup with a cleaning solution

or water, depending upon material used.

Place cleaning solution into cup and install

on gun. Spray solution through the gun until

it sprays clear. Do NOT immerse the entire

gun in solvent.

2.

Disconnect air hose from tool.

3.

Remove air cap and clean. Make sure holes

in horns are clean.

4. Use solvent and the provided brush to

remove any deposits around fluid nozzle.

5. For more detailed cleaning, use provided

spanner to remove fluid control knob, fluid

nozzle, and needle (in that order). Clean

nozzle and needle with brush and solution.

Reassemble parts by reversing above order.

6. Periodically lubricate the gun. Use a light

machine oil (Air Tool Oil or SAE #10) on the

following areas. Do not

use lubricants

containing silicone.

•

Fluid needle packing (to prevent needle

from sticking)

•

Air valve packing

•

Trigger

pivot

point

•

Threaded

parts

Storage

Hang the spray gun by its hook when not in use,

to prevent leaks or blockages. Disconnect air

hose before storage.

Air system requirements

1. Use proper air hose size (refer to tool

specifications). The hose should be just long

enough to serve the working area. Excessive

hose length will cause pressure drop.

2. Make sure air compressor supplies clean,

dry air at correct CFM for tool.

3. Set air pressure according to tool

specifications.

Excess air pressure

and/or unclean air will shorten the tool’s

life and may create a hazardous situation.

4.

Drain water from air compressor tank daily,

as well as any condensation from air lines.

Water in the air line may enter the tool and

cause damage.

5.

Change filters on the air system on a regular

basis.