JET

7

Maintenance

Lubrication

The air riveter should be lubricated daily (or before

each use) with air tool oil through the air inlet.

During continual operation, it should be re-oiled

every 1 to 2 hours. This can be done with an in-

line oiler, or manually. If done manually, proceed

as follows:

1.

Disconnect air hose from tool.

2.

Place 4 or 5 drops of air tool oil into air inlet

(Figure 1).

NOTE: Air tool oil not provided; it is available

at most major hardware and tool stores. SAE

#10 oil or sewing machine oil may be used

as a substitute. Do not use detergent oil.

3.

Re-connect air. Fire riveter several times to

distribute the oil throughout tool.

4.

When finished operating riveter, disconnect

air hose. Wipe off housing with a dry cloth.

Place 4 or 5 drops of air tool oil into air inlet;

re-connect air and fire tool several times to

distribute the oil. Disconnect air.

Cleaning

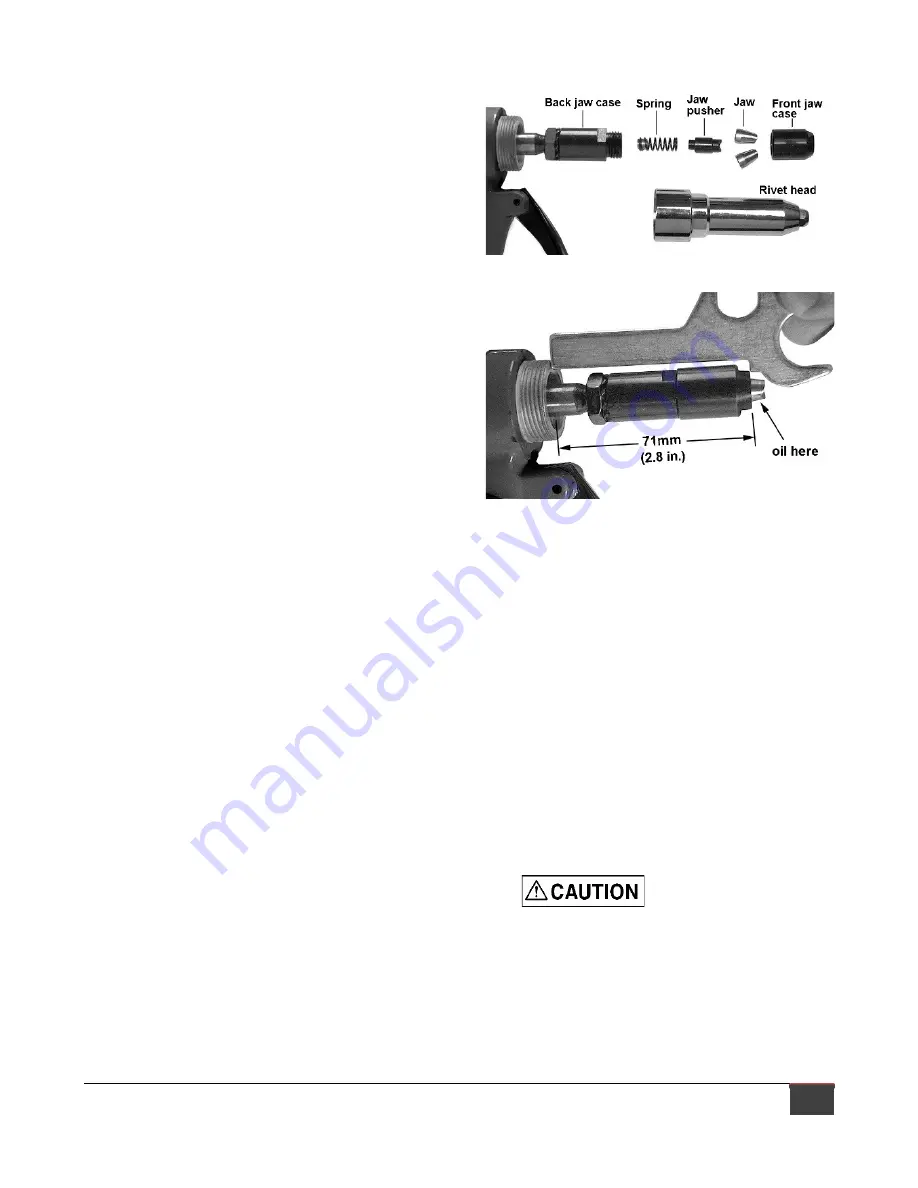

The rivet head and jaw assembly should be

inspected, cleaned and lubricated as needed.

1.

Disconnect riveter from air supply.

2.

Loosen rivet head (Figure 3) with an

adjustable wrench (not provided), and

remove rivet head from nozzle.

3.

Use the provided gauge wrench to

disassembled jaw case, jaw halves, jaw

pusher and the spring.

4.

Clean each of the disassembled parts. Use

a cleaning brush on the internal threads of

the jaw and inside the rivet head.

5.

Reassembled parts in proper order.

6.

Use gauge wrench to check that length of

jaw assembly is correct (Figure 4). This

length ensures proper spring tension. Rotate

jaw assembly as needed until it fits the span

of the gauge as shown.

7.

Apply air tool to outside of jaw halves.

8.

Reinstall rivet head.

Figure 3

Figure 4

Storage

Avoid storing the air riveter in very humid locations

which promotes rusting of internal mechanisms.

Always oil the tool and disconnect air hose before

storage. A hanger is provided for suspending the

tool upright from a hook.

Air system requirements

1.

Use proper air hose size (refer to tool

specifications). The hose should be just long

enough to serve the working area. Excessive

hose length will cause pressure drop.

2.

Make sure air compressor supplies clean,

dry air at correct CFM for the tool.

3.

Set air pressure to 90 psi.

Excess air pressure

and/or unclean air will shorten the tool’s

life and may create a hazardous situation.

4.

Drain water from air compressor tank daily,

as well as any condensation from air lines.

Water in the air line may enter the tool and

cause damage.

5.

Change filters on the air system on a regular

basis.

Summary of Contents for JAT-920 505920

Page 9: ...JET 9 Figure 3 Recommended arrangement of air piping and air line system ...

Page 12: ...12 JAT 920 Pneumatic Riveter 505920 JAT 920 Pneumatic Riveter exploded view ...

Page 14: ...14 JAT 920 Pneumatic Riveter This page intentionally left blank ...