6

Use a forklift or hoist to rise the

machine and place it onto the

assembly fixtures (Z, Fig 6)

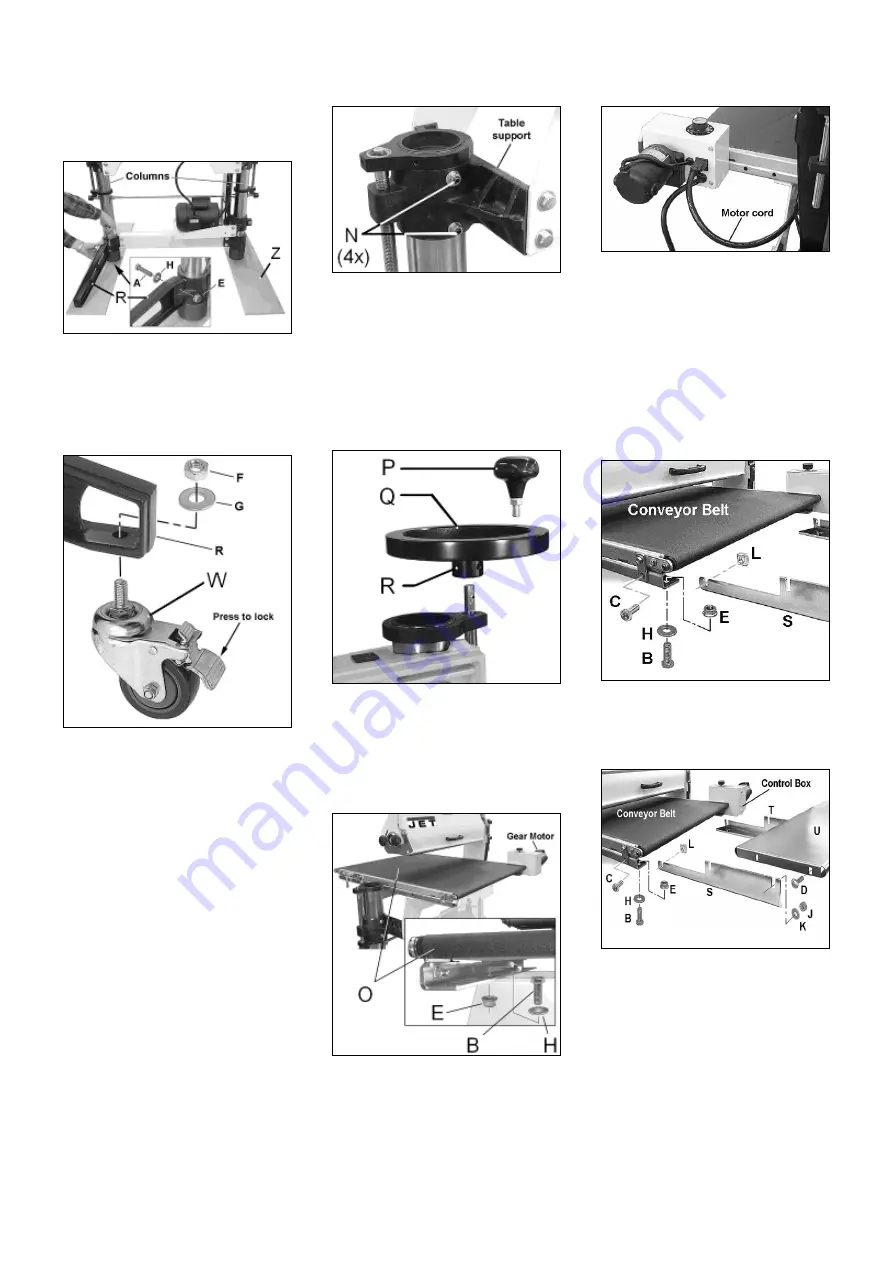

Fig 6

Mount the 4 legs (R) to the columns.

Lift the brush sander and remove the

assembly fixtures.

Mount the 4 wheels (W, Fig 7)

Fig 7

Adjust table support screws

Attention:

The set screws have been tightened

for shipment.

All 4 set screws must be loosened and

re-adjusted before operating the

height adjusting mechanism.

Failure to follow may damage the

miter gears.

Loosen each hex nut, then loosen the

4 set screws (N, Fig 8)

Fig 8

Re-tighten the set screws until they

only lightly touch the column.

Install handwheel

Attach the handwheel and tighten the

two set screws (R, Fig 9) with the

4mm hex wrench supplied

Fig 9

Conveyor Table Installation

Place the conveyor table (O, Fig 10)

onto the mounting brackets.

Secure the conveyor in place with four

hex head bolts, washers and nuts.

Fig 10

Plug the sander's motor cord into the

receptacle of the control box (Fig 11).

Fig 11

Important: The conveyor belt has been

over-tensioned for the purpose of

shipping.

Before operation, adjust the belt

tension (see chapter 7.5).

Install table extensions

Remove the hex bolt from the rail (C,

Fig 9)

Fig 9

Slide the supports (S, T, Fig 10) into

the rails and attach with bolts and

nuts.

Fig 10

Note:

You have to remove the control box

bottom cover to mount the right

support (T).

Install the tables (U).

Align the extension tables with the

help of a straight edge or a straight

piece of wood (Fig 11).