10

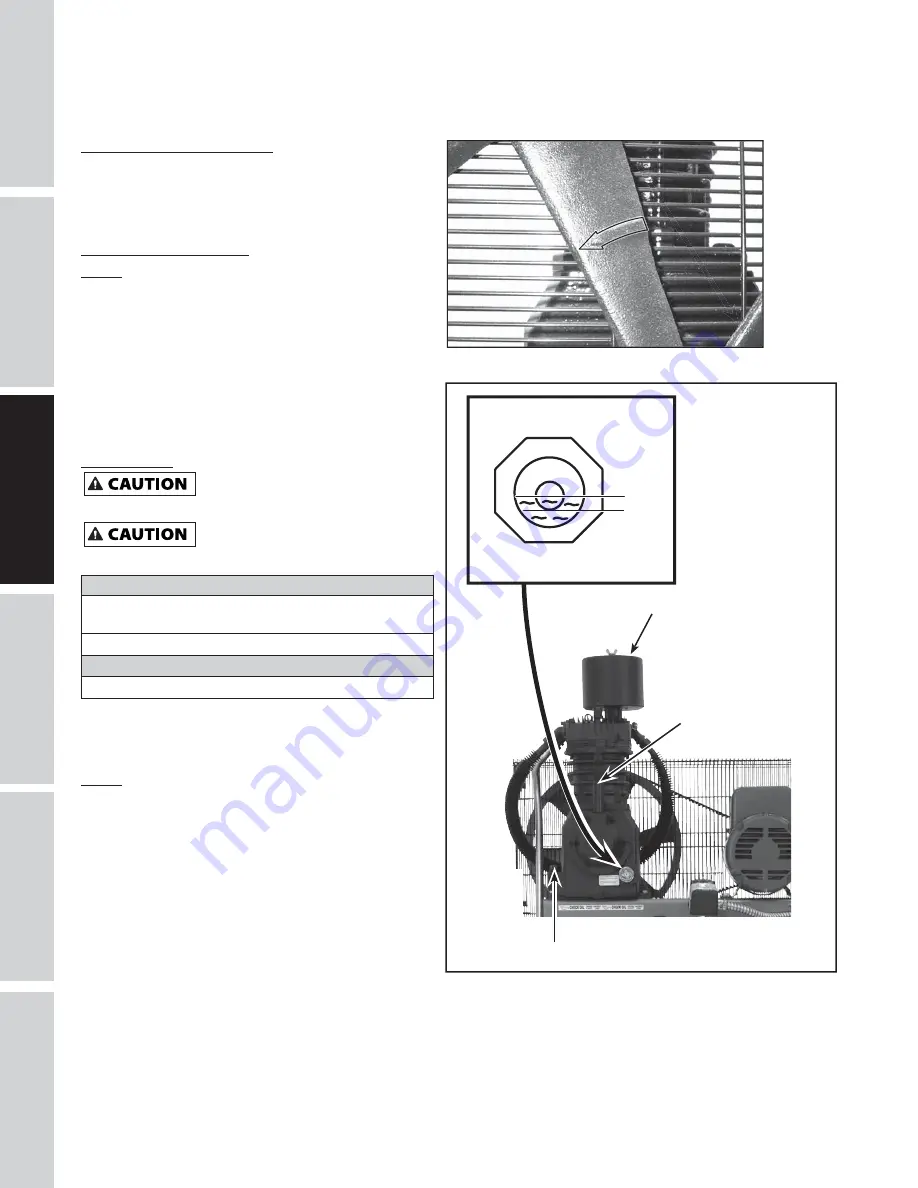

Installing Air Inlet Filter

Use supplied self tapping screws to fasten inlet filter housing

to the head of the pump. Then assemble pump with filter

inside. See Figure 7.

Direction of Rotation

NOTE: Improper rotation will result in reduced compressor

life.

The direction of rotation must be counterclockwise (as

shown by the arrow on the flywheel in Figure 6) while facing

the flywheel side of the pump. The motor nameplate will

show wiring information for counterclockwise rotation.

The proper direction is very important. The direction of

rotation of 3 phase motors can be reversed by interchanging

any two motor-line leads. For single phase motors, refer to

the motor nameplate.

Lubrication

This unit contains no oil. Before

operating compressor, fill to the center

of the sight gauge (see Figure 7).

Using any other type of oil may

shorten pump life and damage valves.

Recommended Oil (2 Options)

Single viscosity SAE 30 ISO100 nondetergent

compressor oil.

10W30 synthetic oil such as Mobil 1

®

.

Oil Capacity

Approximately 2 quarts

Fill the pump with oil to the center of the sight gauge using

oil fill opening (see Figure 7).

Do NOT fill the pump through

the breather cap opening as this may cause oil to leak and

spray out during operation.

NOTE: Some residual oil may still be in the pump from

factory testing leaving a thin coat on the sight gauge;

however, there is not enough oil to operate the unit.

Figure 7

Breather Cap

Oil Fill Port

Sight Gauge

Full

Low

Figure 6- Direction of rotation

INSTALLATION INSTRUCTIONS (CONTINUED)

MAINTENANCE /

REP

AIR

TROUBLESHOOTING

OPERA

TION

ASSEMBL

Y

/

INST

ALLA

TION

SAFETY

/

SPECIFICA

TIONS

GETTING

ST

ARTED

Inlet Filter