JET

5

Tool Specifications

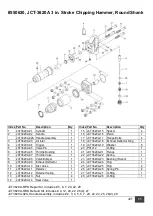

Model number

JCT-3620A

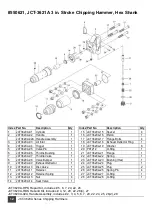

JCT-3621A

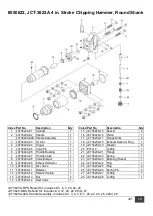

JCT-3622A

JCT-3623A

Stock number

550620

550621

550622

550623

Shank bushing style

Round

Hex

Round

Hex

Shank bushing size

0.680 in.

0.580 in.

0.680 in.

0.580 in.

Stroke length

3 in.

3 in.

4-1/4 in.

4-1/4 in.

Bore size

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

Impact rate

2,300 BPM

2,300 BPM

1,700 BPM

1,700 BPM

Actual air consumption

27.6 CFM

27.6 CFM

30 CFM

30 CFM

Average air consumption 6.9 CFM

6.9 CFM

7.5 CFM

7.5 CFM

Air Inlet

3/8 in. NPT

3/8 in. NPT

3/8 in. NPT

3/8 in. NPT

Air hose minimum inside

diameter

1/2 in.

1/2 in.

1/2 in.

1/2 in.

Required air pressure

90 psi (6.2 bar)

90 psi (6.2 bar)

90 psi (6.2 bar)

90 psi (6.2 bar)

Energy per blow @90psi 21.3 Joules

21.3 Joules

30.1 Joules

30.1 Joules

Vibration value

15.73 m/s

2

15.73 m/s

2

16.08 m/s

2

16.08 m/s

2

Noise level

1

96 dB(A)

96 dB(A)

96 dB(A)

96 dB(A)

Speed settings

Variable throttle

Variable throttle

Variable throttle

Variable throttle

Overall length

14.5 in. (369 mm) 14.5 in. (369 mm) 16.08 in. (426mm) 16.08 in. (426mm)

Housing material

Steel

Steel

Steel

Steel

Net weight

17 lb (7.7 kg)

17 lb (7.7 kg)

19 lb (8.9 kg)

19 lb (8.9 kg)

Shipping weight

19 lb (8.3 kg)

19 lb (8.3 kg)

21 lb (9.3 kg)

21 lb (9.3 kg)

1

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As

workplace conditions vary, this information is intended to allow the user to make a better estimation of the

hazards and risks involved only.

Specifications were current at time of publication, but because of our policy of continuous improvement, JET

reserves the right to change specifications at any time and without prior notice, without incurring obligations.