7

Do not use wire wheels, router bits,

shaper cutters, circle cutters, or rotary

planers on this drill press.

Never cut magnesium-

high danger of fire!

7. Setup and adjustments

General note:

Setup and adjustment work may

only be carried out after the

machine is protected against

accidental starting by pulling the

mains plug.

7.1 Removing the Chuck and Arbor

Unplug the machine from the power

source.

Lower the quill using the down feed

handle.

Rotate the spindle to align the key in

the spindle with the key hole in the

quill.

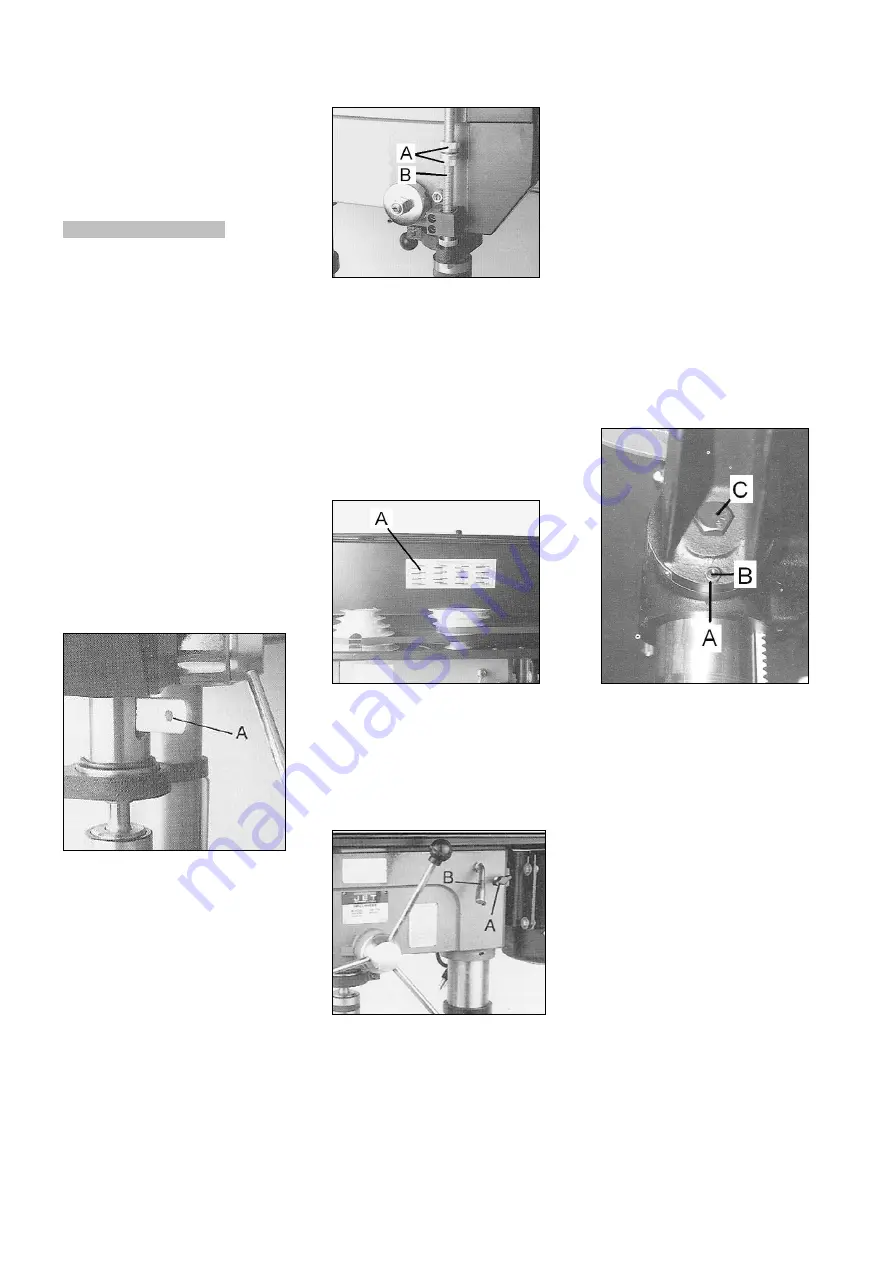

Insert the drift key (A, Fig 9) into the

aligned slots and tap lightly. Have

another person (or a protected table)

catch the chuck and arbor assembly

as it falls away from the spindle.

Fig 9

7.2 Adjusting the Depth Stop

To drill multiple holes at the same

preset depth, use the depth stop:

With the drill bit in the chuck, lower

the down feed handle to advance the

chuck to the desired point.

With your other hand, advance the

lock nuts (A, Fig. 10) on the depth

stop (B, Fig. 10) until they touch the

stop bracket.

Fig 10

The drill bit will now advance only to

this point.

7.3 Changing Spindle Speeds

Loosen the locking screw on the

pulley cover, then open the cover.

A spindle speed and belt arrangement

chart is found on the inside of the belt

cover (A, Fig 11). Refer to this chart

whenever changing speeds.

Fig 11

To change spindle speeds:

Unplug the machine from the power

source.

Loosen two side bar bolts found on

each side of the head assembly. (A,

Fig 12).

Fig 12

Rotate the tension adjuster (B) to

bring the motor base as close to the

head as possible.

Change the belts location according

the speed chart and the speed you

desire.

Rotate the tension adjuster (B) to

tension the belts.

Tighten two slide bar bolts (A, Fig.

12). Belts are properly tensioned when

finger and thumb pressure midway

between the two pulleys causes

approximately 10 mm deflection.

Close and lock the pulley cover.

7.4 Table Tilt Adjustment

Disconnect the machine from the

power source (unplug).

Remove the alignment pin (B, Fig 13)

first by turning the nut (A) clockwise.

Fig 13

Loosen the hex cap bolt (C) to tilt the

table.

Caution:

Only loosen the hex cap bolt slightly,

otherwise the table assembly will

separate from the column and fall.

Tighten the hex cap bolt.

The alignment pin only works at 90

°

and must be reinserted when the table

is returned to 90

°

.

7.5 Return Spring Adjustment

Disconnect the machine from the

power source (unplug).

The return spring is adjusted at the

factory and should not need further

adjustment. If adjustment is

necessary:

Unplug the machine from the power

source.

Loosen two lock nuts (A, Fig 14)

approximately 6mm.