13

fence until the angle of the fence matches

the bevel of your gauge piece.

5. Tighten locking handle (C, Fig 8-2).

4.

Important:

When the tilted operation is

finished and the fence is returned to 90°, do

not forget to flip the 90° stop block (D, Fig.

8-2) back to its original position.

To tilt fence backward

5. The fence can be tilted backward up to 45°

(that is, for a total included angle of 135°

from table surface).

6. Loosen locking handle (C, Fig. 8-2).

7. Flip the 90° stop block (D, Fig. 8-2) out of

the way.

8. Move the lever (B, Fig. 8-2) back to the

desired angle up to 135 degrees. Or you can

place

8.3

Fence stop adjustments

Periodically check the 90° and 45° backward

(135°) tilt accuracy of the fence with an angle

measuring device, such as an adjustable square

or machinist’s protractor.

90º Fence adjustment

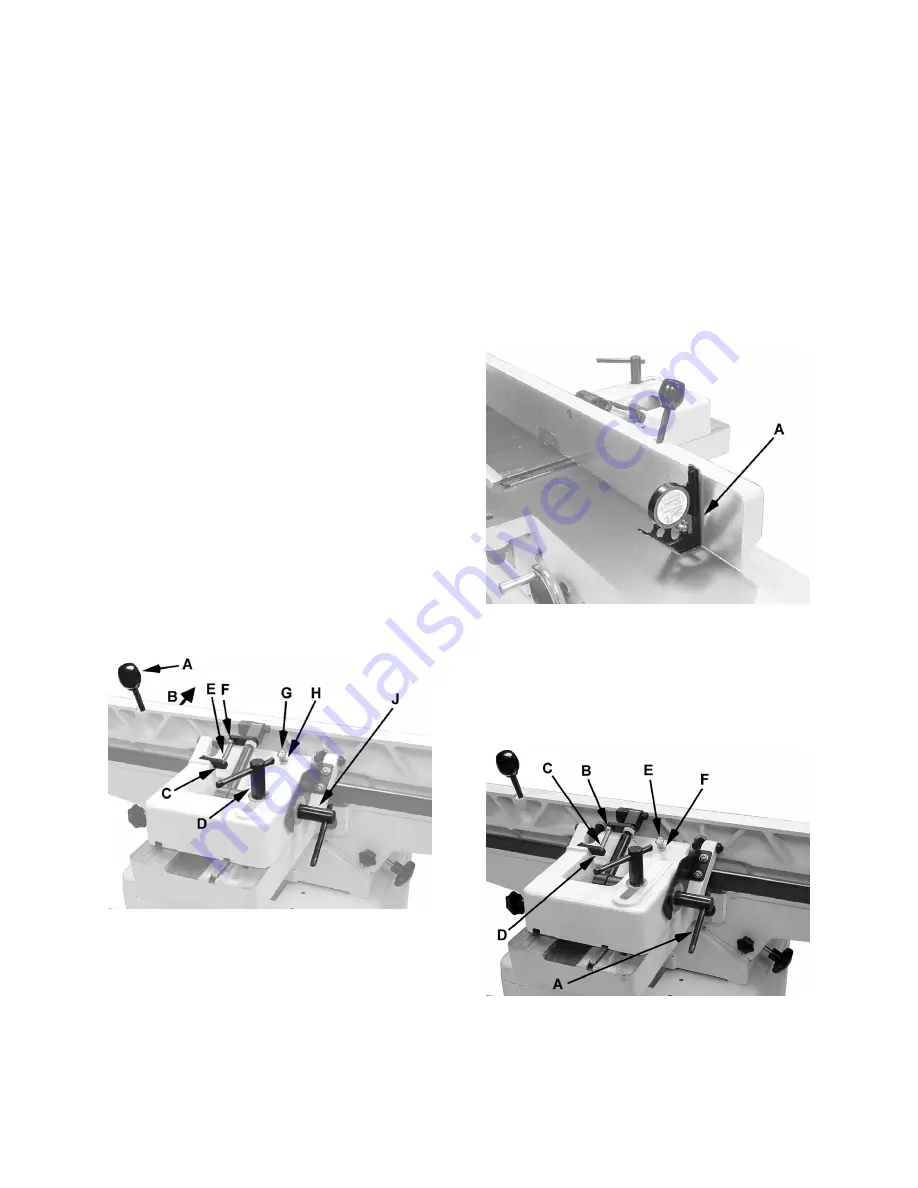

Refer to Figure 8-3:

The 90º stop is controlled by the

stop bolt

(E)

and the

stop plate

(C).

Figure 8-3

1. Set the infeed table to approximately the

same height as the outfeed table.

2. Move the fence by releasing

lock handle

(D)

and pushing the fence assembly until it

overlaps the tables (B).

3. Tighten

lock handle

(D).

4. Adjust the fence to a 90º angle by releasing

lock handle

(J), pulling up on the

fence

handle

(A), and tightening the

lock handle

(J).

Note:

The

stop bolt

(E) should be resting

against the

stop plate

(C).

5. Place an angle measuring device on the

table and against the fence to confirm a 90º

setting (A, Fig. 84).

6. If the fence is not square to the table,

release the

lock handle

(J), loosen the hex

nut (F), and turn the

stop bolt

(E) until the

fence is square to the table.

7. Tighten the lock nut (F) to retain the setting.

Tighten the lock handle (J).

Figure 8-4

45º Fence backward stop adjustment

Refer to Figure 8-5:

The 45º fence backward stop (fence positioned

away from the operator) is controlled by the

stop

bolt

(E).

Figure 8-5

1. Loosen the lock handle (A). Move the stop

plate (D) out of the way and position the

fence at the 135º angle. Make sure the

fence sits against the stop bolt. (E).

Summary of Contents for JJ-6HHDX

Page 27: ...27 15 1 1 Fence Assembly All Models Exploded View...

Page 29: ...29 15 2 1 Stand Assembly JJ 6CSDX Exploded View...

Page 31: ...31 15 3 1 Stand Assembly JJ 6HHDX only Exploded View...

Page 33: ...33 15 4 1 Bed Assembly All models Exploded View...

Page 37: ...37 16 0 Wiring diagrams All Models...

Page 39: ...39 This page intentionally left blank...

Page 40: ...40 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...