17

8. Replace the remaining two blades by

repeating steps 1 – 7.

9. Determine if knives need to be set.

Follow the

Outfeed Table Adjustment

section

steps 3 and 4 only to determine if

knives need to be set.

Do not complete the

entire outfeed table adjustment

. If knives

need to be set, proceed to the

Setting

Cutterhead Knives

section.

8.9

Setting knives for rabbeting and

nicks

(NOTE: Rabbeting is not applicable to the JJ-

6HHDX helical head jointer)

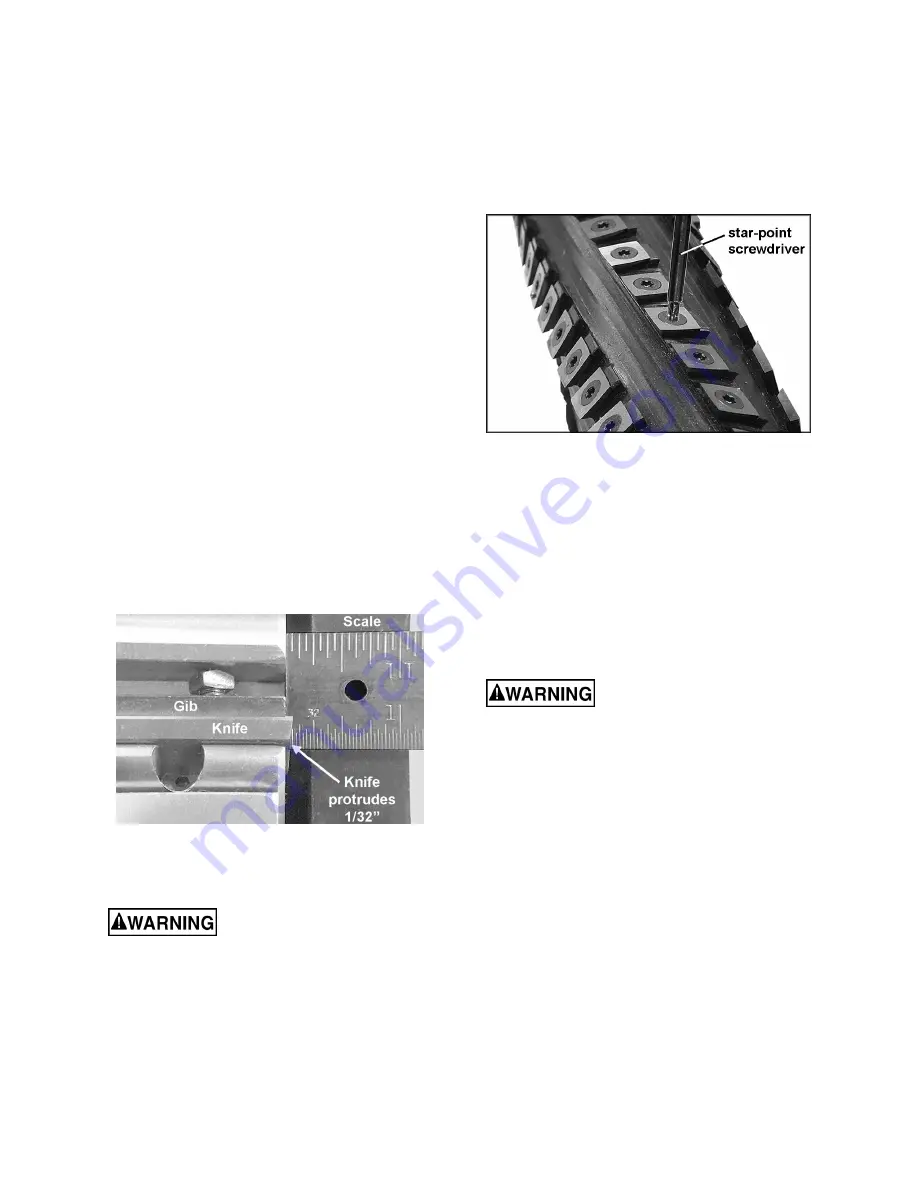

To position the knives for rabbet cuts, take a

shop scale with 1/32” graduations and place it

against the end of the cutterhead. Slide the knife

out until it is at the 1/32” mark on the scale; that

is, the knife will now be 1/32” beyond the edge

of the cutterhead. The gib should remain in

normal position, even with the edge of the

cutterhead. (Figure 30). This adjustment will

ensure that the knife clears the end of the gib

and cutterhead, and has good contact with the

workpiece. (See the

Rabbeting

section for

further information.)

Note:

This will also correct for small nicks

without requiring replacement of knives.

Figure 8-14

8.10

Rotating and replacing knife

inserts (JJ-6HHDX)

Knife inserts are dangerously

sharp. Use extreme caution when inspecting,

removing, or replacing knife inserts.

The knife inserts on the model JJ-6HHDX

Jointer are four-sided. When dull, simply remove

each insert, rotate it 90° for a fresh edge, and re-

install it. No further adjustment is necessary.

Use the two provided star point screwdrivers to

remove the knife insert screw. Use one of the

screwdrivers to help hold the cutterhead in

position, and the other to remove the screw. See

Figure 8-15. It is advisable to rotate all inserts at

the same time to maintain consistent cutting.

However, if one or more knife inserts develops a

nick, rotate only those inserts that are affected.

Each knife insert has an etched reference mark

so you can keep track of the rotations.

Figure 8-15 – HH models only

IMPORTANT:

When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform. Dust

accumulation between these elements can

prevent the insert from seating properly, and

may affect the quality of the cut.

Before installing each screw, lightly coat the

screw threads with machine oil and wipe off any

excess.

Securely tighten each screw which holds the

knife inserts before operating the planer!

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propelled at high speed from a

rotating cutterhead, causing injury.

8.11

Determining correct table height

When you receive the jointer, the knives have

been pre-set at the factory. However, the height

and parallelism of the knives with the outfeed

table should be checked, and any needed

adjustments made, before putting the jointer into

operation.

The

outfeed table

and

cutterhead knives

are

correctly adjusted when all three blades are

parallel to the outfeed table and all three blades

are set at the same height in the cutterhead.

Summary of Contents for JJ-6HHDX

Page 27: ...27 15 1 1 Fence Assembly All Models Exploded View...

Page 29: ...29 15 2 1 Stand Assembly JJ 6CSDX Exploded View...

Page 31: ...31 15 3 1 Stand Assembly JJ 6HHDX only Exploded View...

Page 33: ...33 15 4 1 Bed Assembly All models Exploded View...

Page 37: ...37 16 0 Wiring diagrams All Models...

Page 39: ...39 This page intentionally left blank...

Page 40: ...40 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com...