20

Beveling

Beveling an edge is the same operation as edge

jointing, except that the fence is tilted to a

specified angle.

!

Make certain material being beveled is over

12 inches long, more than 1/4 inch thick and

1 inch wide.

To bevel:

1. Use a bevel gauge to determine the desired

angle. Then set the fence to the same angle.

2. Inspect stock for soundness and grain

direction (refer to

Direction of Grain

on

previous page).

3. Set the infeed table for a cut of

approximately 1/16.

4. If the board is bowed (curved), place the

concave edge down on the infeed table.

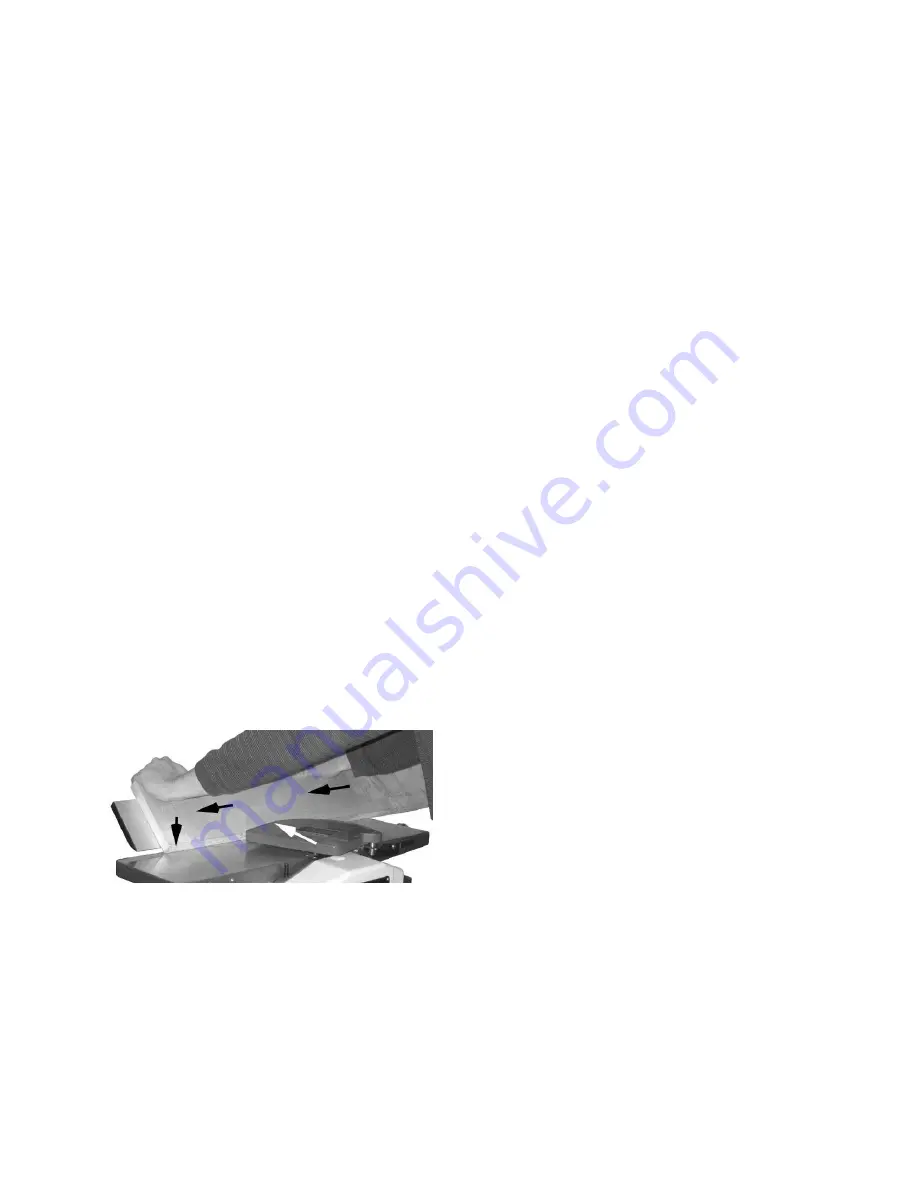

5. Feed the stock through the cutterhead,

making sure the face of the stock is

completely flat against the fence and the

edge is making solid contact on the infeed

and outfeed tables (Figure 23).

For wood wider than 3 inches –

hold with

fingers close together near the top of the

stock, lapping over the board and extending

over the fence.

For wood less than 3 inches wide

– use

beveled push blocks and apply pressure

toward the fence. Keep fingers near top of

push block.

Several passes may be required to achieve full

bevel.

Figure 23

Planer Operations

Depth of Cut

Thickness planing refers to the sizing of lumber to

a desired thickness while creating a level surface

parallel to the opposite side of the board. Board

thickness that the planer will produce is indicated

by the

scale

(see

Table Height Adjustment

on

page 13). Preset the planer to the desired

thickness of the finished workpiece using the

gauge. The depth-of-cut is adjusted by raising or

lowering the

planer table

(D, Fig. 12) using the

adjustable handle

(C, Fig. 12).

!

The quality of thickness planing depends on

the operator's judgment about the depth of

cut.

!

The depth of cut depends on the width,

hardness, dampness, grain direction and

grain structure of the wood.

!

The maximum thickness of wood that can be

removed in one pass is 5/64" for planing

operations on workpieces up to 5-1/2” wide.

The workpiece must be positioned away from

the center tab on the rollercase to cut 1/8”.

!

The maximum thickness of wood that can be

removed in one pass is 1/16” for planing

operations on workpieces from 5-1/2” up to

10" wide.

!

For optimum planing performance, the depth

of cut should be less than 1/16”.

!

The board should be planed with shallow

cuts until the work has a level side. Once a

level surface has been created, flip the

lumber and create parallel sides.

!

Plane alternate sides until the desired thick-

ness is obtained. When half of the total cut

has been taken from each side, the board

will have a uniform, moisture content and

additional drying will not cause it to warp.

!

The depth of cut should be shallower when

the workpiece is wider.

!

When planing hardwood, take light cuts or

plane the wood in thin widths.

!

Make a test cut with a test piece and verify

the thickness produced.

!

Check the accuracy of the test cut before

working on the finished product.

Precautions

!

A thickness planer is a precision wood-

working machine and should be used on

quality lumber only.

!

Do not plane dirty boards; dirt and small

stones are abrasive and will wear out the

blade.

!

Remove nails and staples. Use the planer to

cut wood only.

!

Avoid knots. Heavily cross-grained wood

makes knots hard. Knots can come lose and

jam the blade. Any article that encounters

planer blades may be forcibly ejected from

the planer creating a risk of injury.

Summary of Contents for JJP-10BTOS

Page 30: ...30 10 JOINTER PLANER ASSEMBLY DRAWING INDEX ...

Page 31: ...31 Planer Table Assembly ...

Page 32: ...32 Motor Front Frame Assembly 143 ...

Page 33: ...33 Chain Drive Assembly Front Cover Assembly ...

Page 34: ...34 Cutterhead Guard Assembly Dust Cover Assembly ...

Page 35: ...35 Jointer Infeed Table Assembly Jointer Outfeed Table Assembly 10 ...

Page 36: ...36 Cutter Head Feed Roller Assembly Jointer Fence Assembly ...